Steel pipe integral girders for constructing prestressing force and construction method thereof

A prestressed steel and prestressed technology, which is applied to the prestressed steel pipe integral truss and its construction field, can solve the problems of increased deformation of the overall truss, difficulty in realizing rigid connection of nodes, and large cross-section of local members, etc., to improve the bearing capacity Force and stiffness, high load-bearing capacity, effect of increased load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

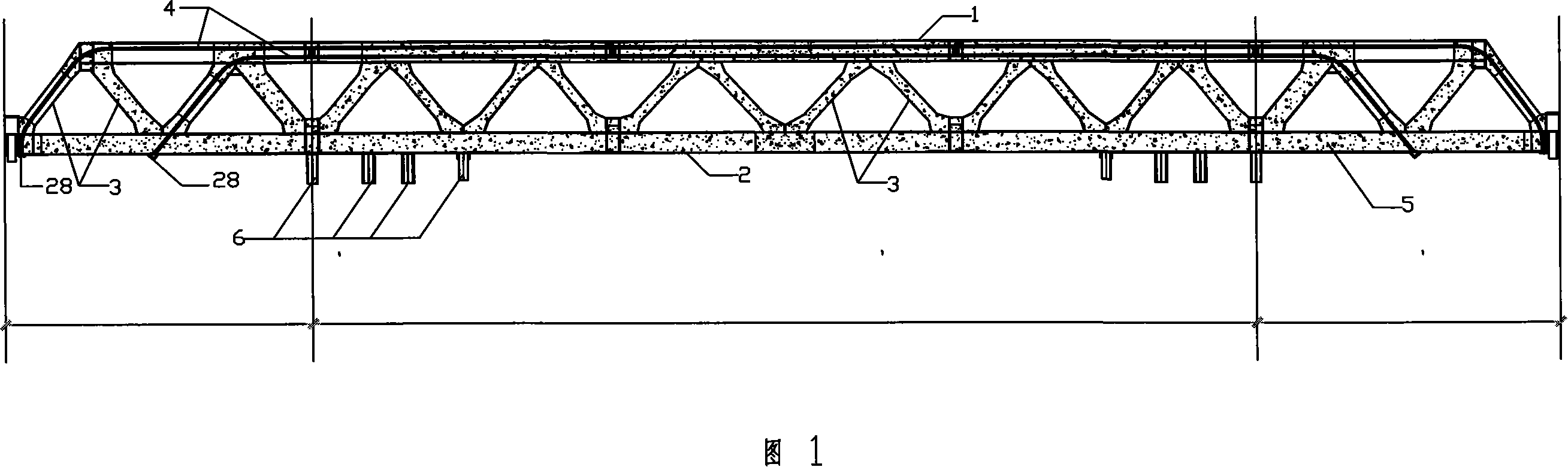

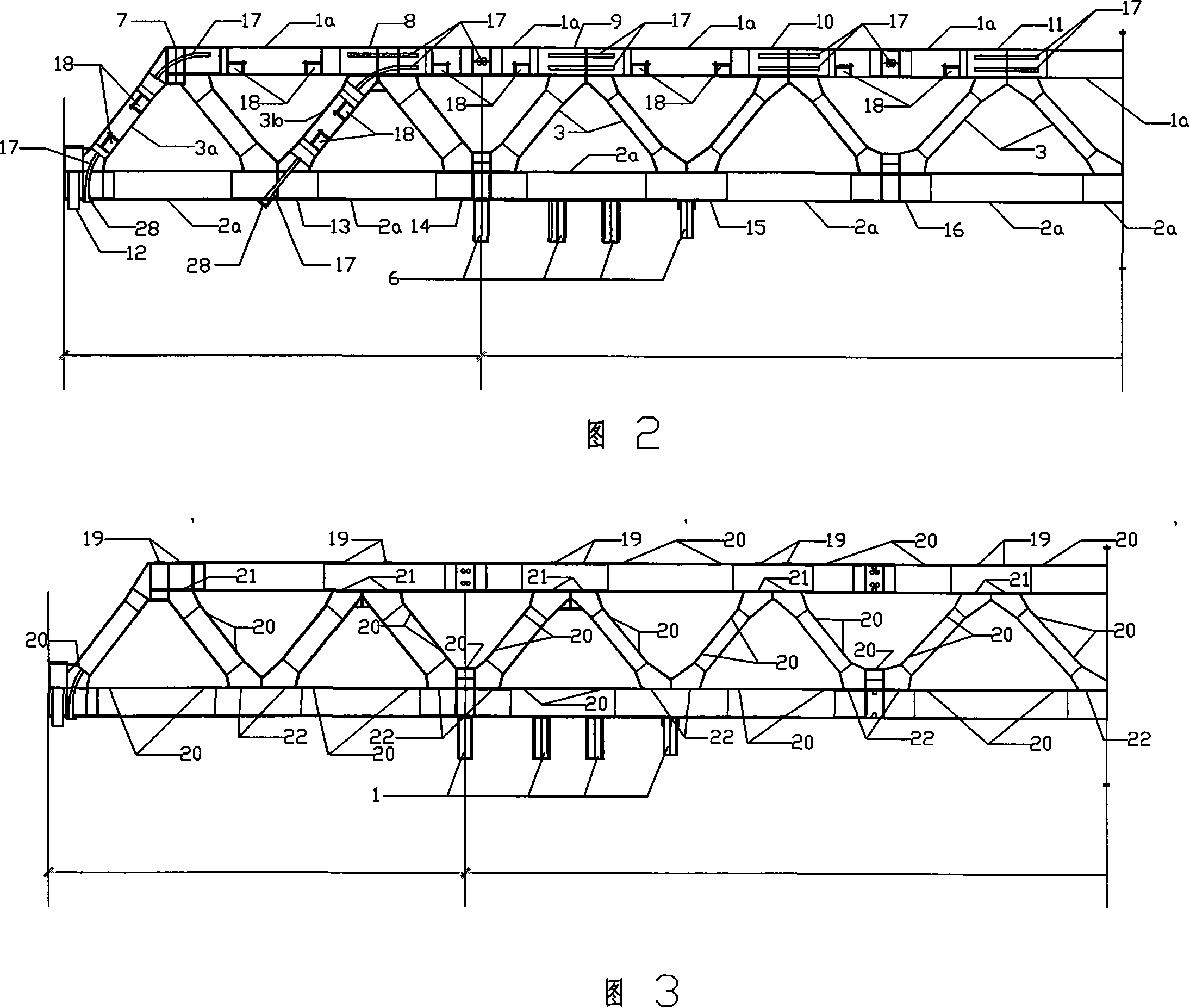

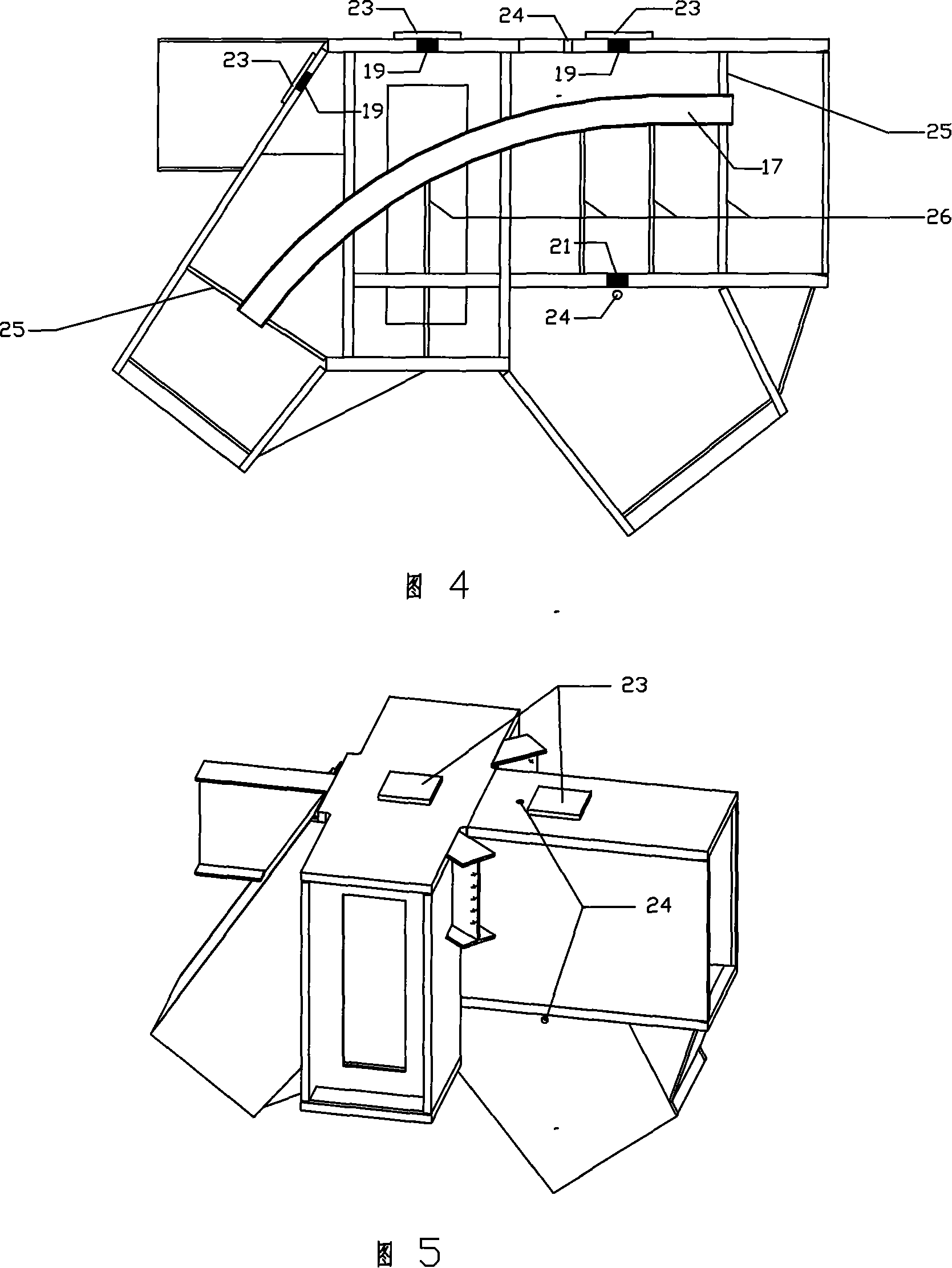

Embodiment 1

[0113] Embodiment 1 of the present invention is shown in Figures 1 to 17. In this embodiment, the prestressed steel pipe integral truss described in the present invention is the main force-bearing truss used in a large-span suspension structure, and the components that make up the truss Including rods and nodes, the rods include upper chord 1, chords 1a, 2a of lower chord 2 and web 3, and a cantilever support 6 is provided under the lower chord 2 of the truss. The chords 1a, 2a and web 3 of the upper chord 1 and lower chord 2 of the truss are all steel pipes with rectangular cross-section; the chords 1a, 2a of the upper chord 1 and lower chord 2 and the web 3 are connected by "K" type nodes, The vertical sides of the "K" type joints are arranged horizontally and connected with the chords 1a and 2a; the two hypotenuses of the "K" type joints are connected with the inclined webs 3; The guide wire hole through which the hinge line 4 passes, the guide wire hole is arranged on the ...

Embodiment 2

[0124] Embodiment 2 of the present invention is shown in 18 and 19. The difference from the previous embodiment is that in this embodiment, the prestressed integral truss described in the invention is used in a large-span structure. The upper chord of the truss 1, The chords 1a, 2a of the lower chord 2 and the web 3 are rigidly connected "K" joints, and the end of the lower chord 2 is provided with an end support 6a. Contrary to the stress of ordinary cantilever structures, the upper chord 1 of the truss is under compression and the lower chord 2 is under tension, and each node of the lower chord 2 is provided with two pairs of guide cable holes and two horizontal guide cable tubes 17, so the prestressed steel hinge line 4 Set on the chord 2a of the lower chord 2 under tension and the node on the lower chord 2, the two ends of the steel hinge 4 are fixed at the node at the end of the lower chord 2 with riveting heads 28; The internal force of the webbing rod is much smaller th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com