Pilot type control valve

A control valve, pilot-operated technology, applied in the field of control valves, can solve the problems of inability to finely adjust the valve opening, increase in opening area, poor response, etc., achieve good control characteristics and action stability, and speed up pressure equalization. time, noise suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, embodiments of the pilot control valve of the present invention will be described with reference to the drawings.

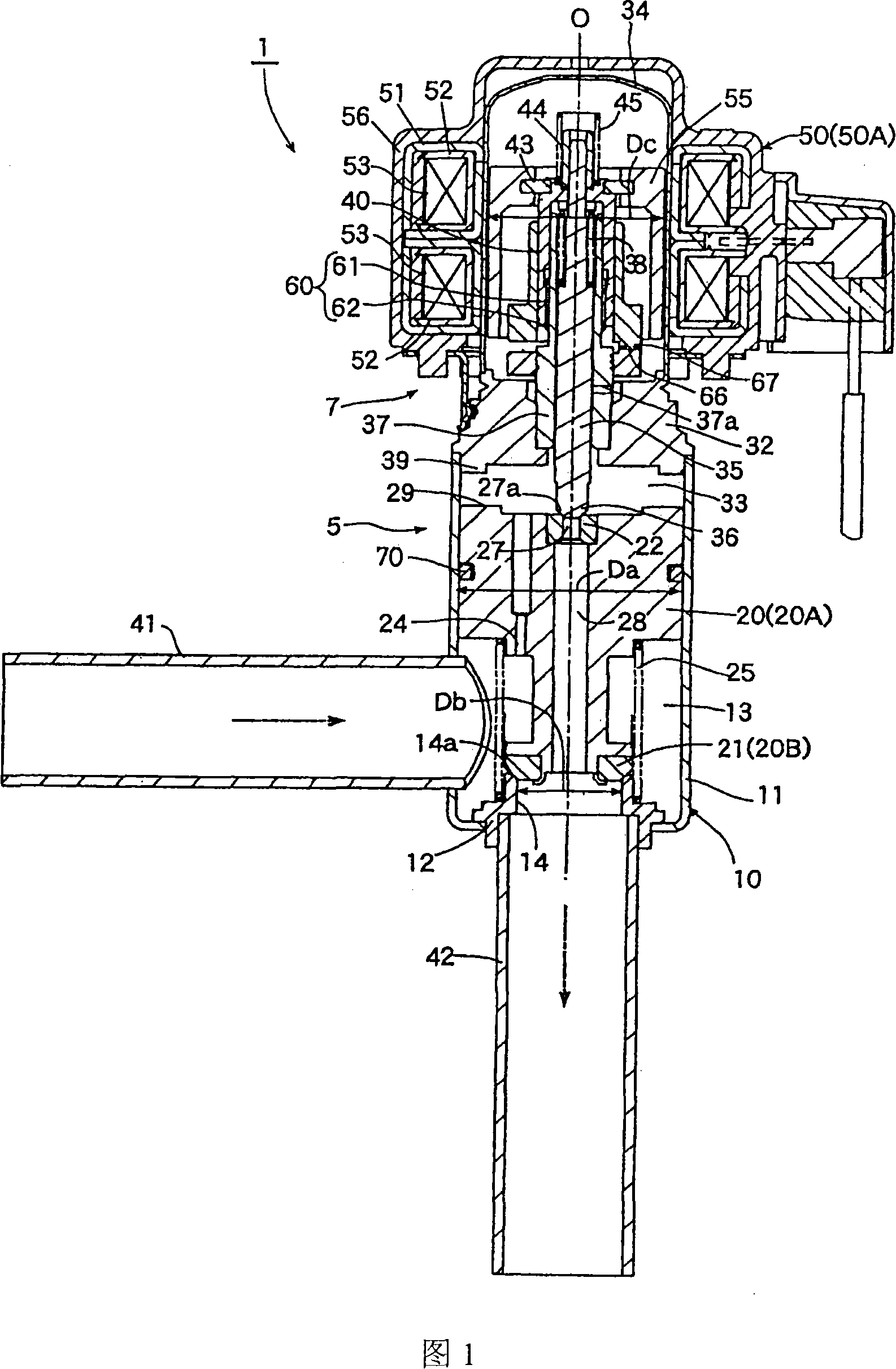

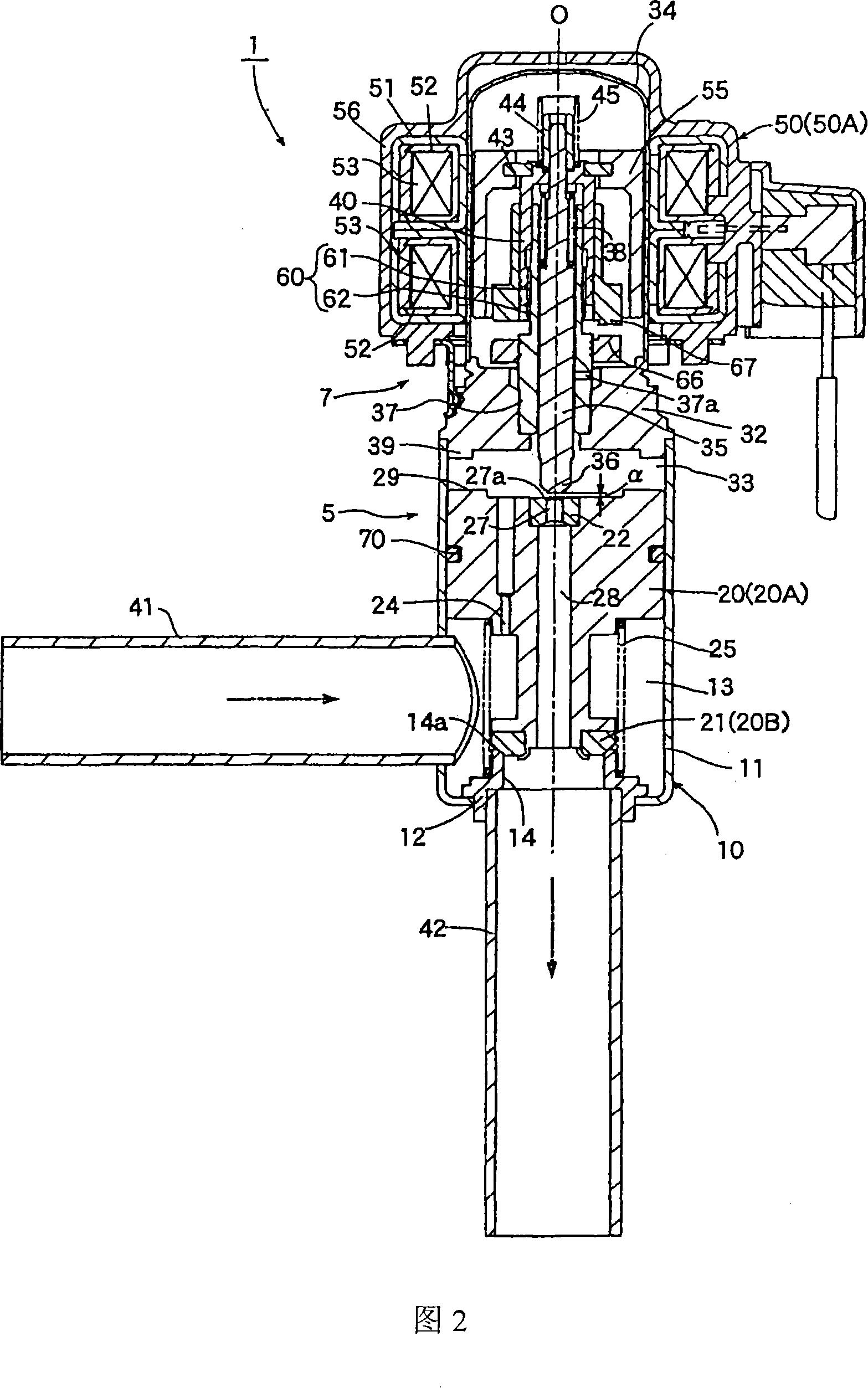

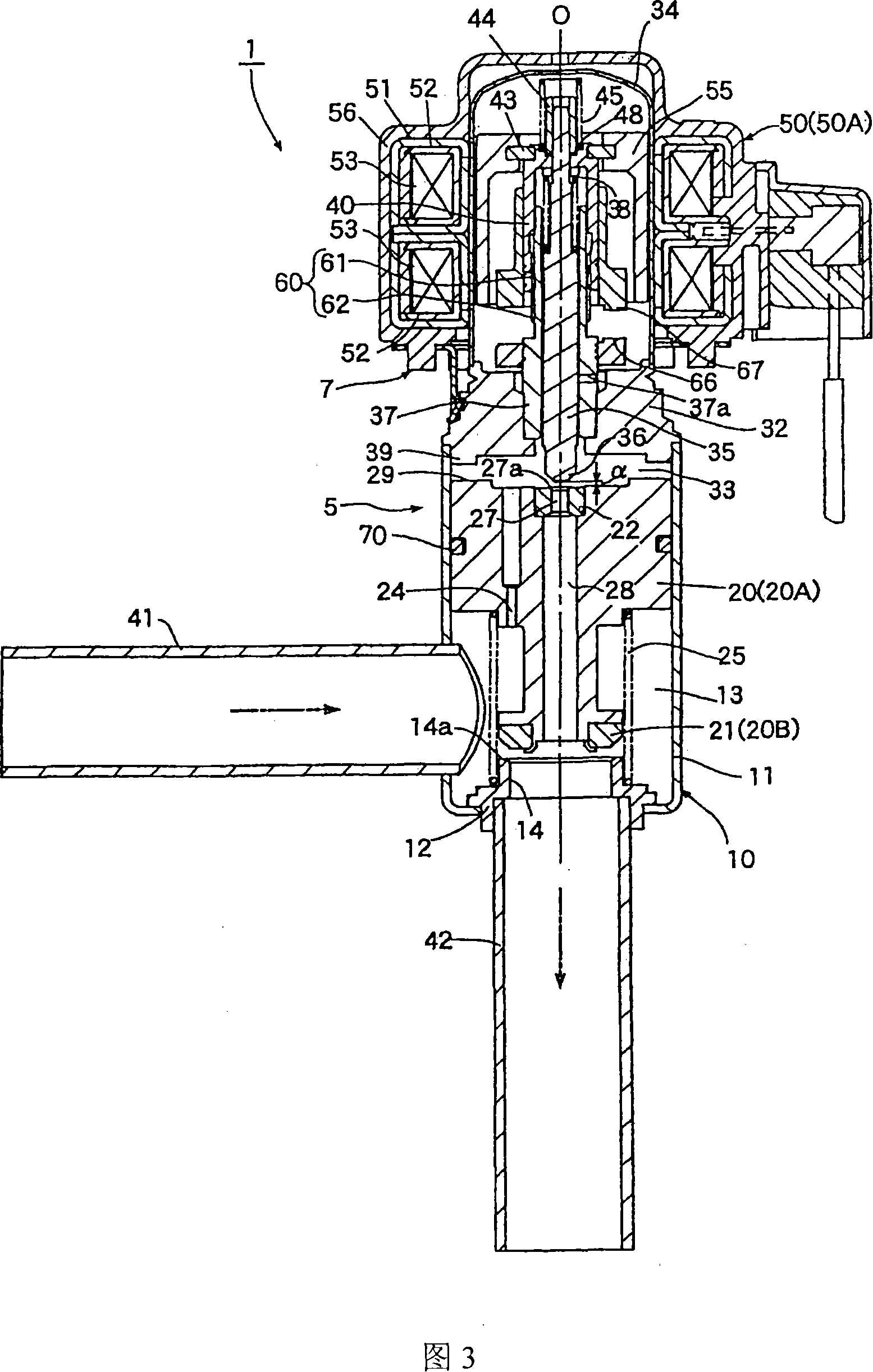

[0026] Fig. 1 is a longitudinal sectional view showing an embodiment of a pilot control valve of the present invention.

[0027] The pilot-operated control valve 1 of the illustrated embodiment is suitable for being arranged between the outdoor unit and the indoor unit in an air conditioner such as a multi-connected air conditioner. Side electric pilot valve 7 constitutes.

[0028] The above-mentioned main valve 5 has a valve body 10, and the valve body 10 includes: a cylindrical valve chamber body 11 with a bottom with a hole; The seat member 12 has a valve chamber 13 formed in the valve body 10. In addition, an inlet conduit (joint) 41 for introducing high-pressure refrigerant into the valve chamber 13 is connected to the outer peripheral side, and at the bottom (valve seat member 12) An outlet pipe (joint) 42 for leading out the refrigera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com