Liquid ejecting apparatus

A liquid and liquid box technology, applied in printing and other directions, can solve problems such as unsuitable operations and achieve the effect of improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

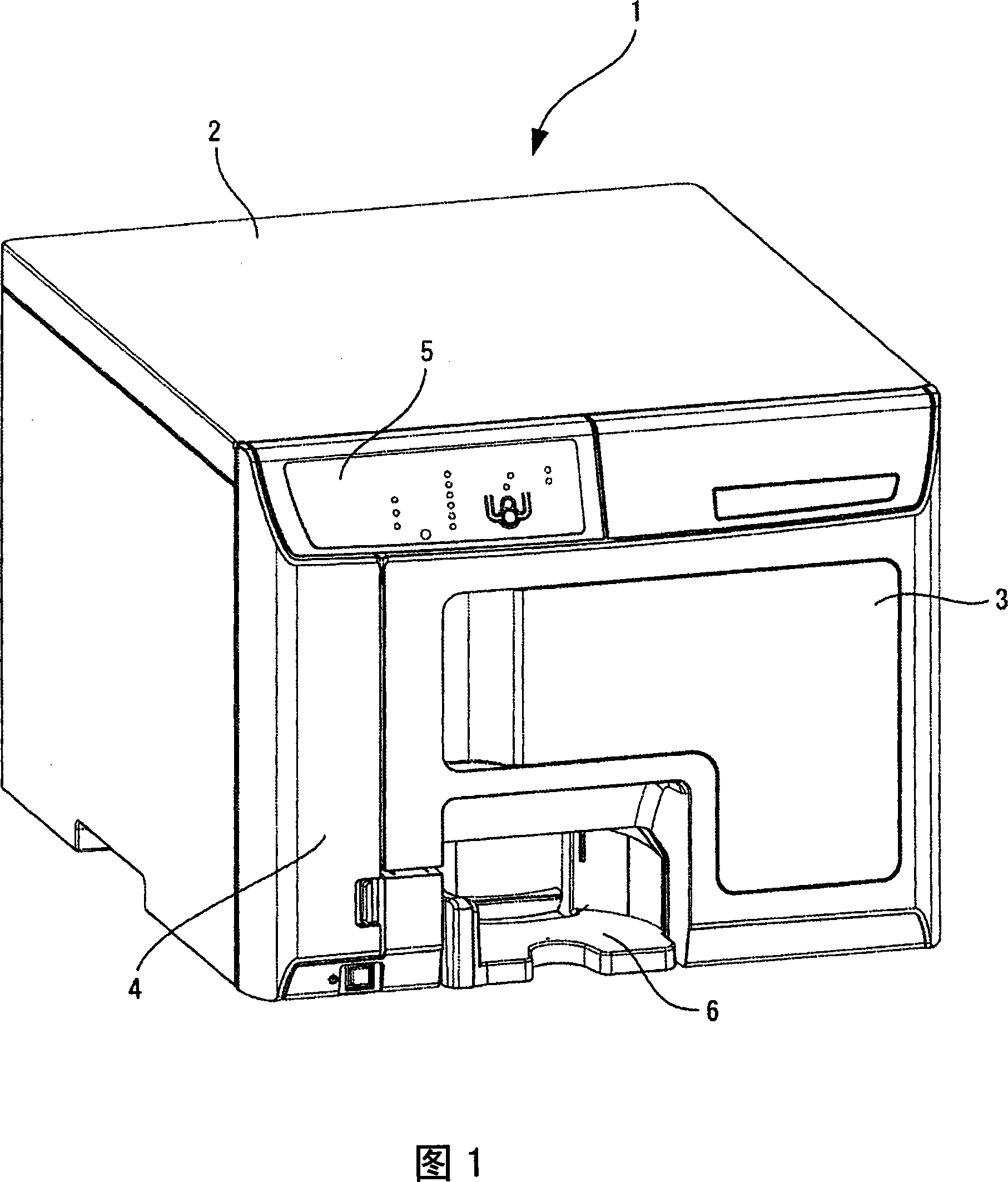

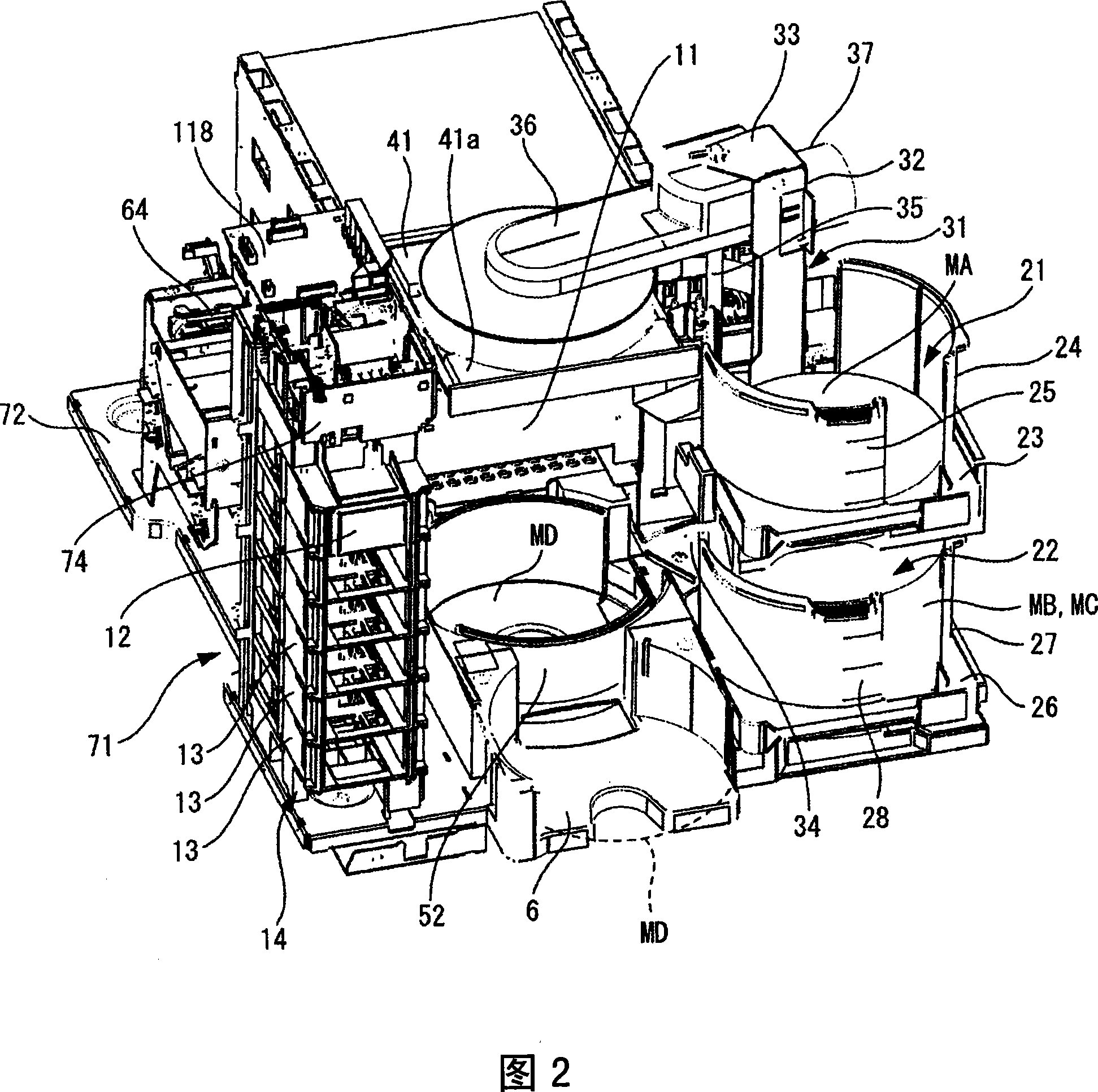

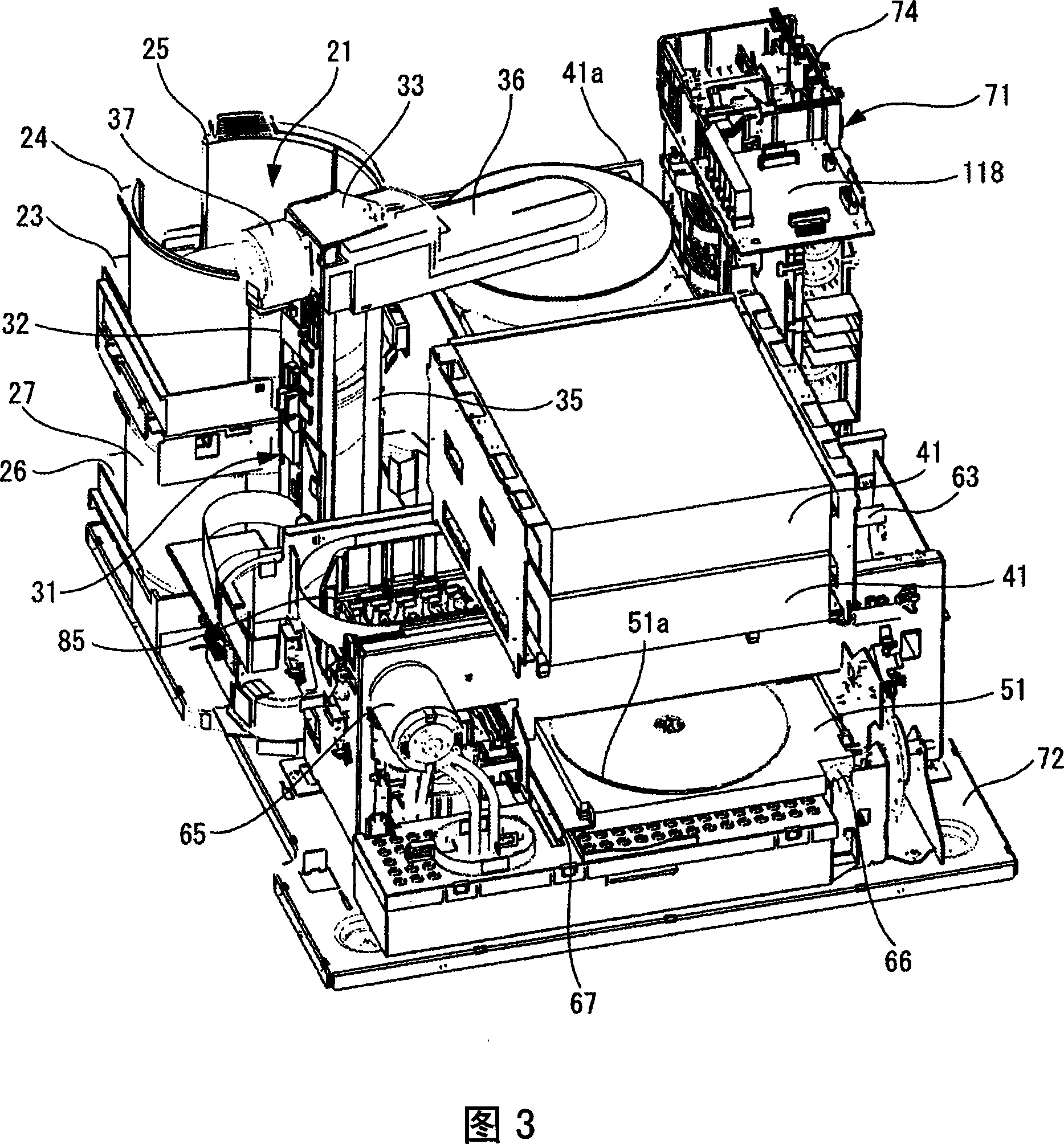

[0075] Hereinafter, an embodiment of a liquid ejecting apparatus including a cartridge holder of the present invention will be described with reference to the drawings.

[0076] In addition, in the present embodiment, a case where the liquid ejecting device is applied to a printing machine as a media processing device will be described as an example.

[0077] 1 is an external perspective view of a printing machine (media processing device), FIG. 2 is a front perspective view of the printing machine with its casing removed, FIG. 3 is a rear perspective view of the printing machine with its casing removed, and FIG. 4 FIG. 5 is a perspective view of a portion of the liquid ejection device installed in the printing machine, and FIG. 5 is a schematic diagram of the internal configuration of the printing machine.

[0078] The printing machine 1 is a media processing device that writes data to a disc-shaped medium such as a CD or a DVD, or prints on a label surface of the medium, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com