Spinning machine with multi-stage drafting compression unit

A spinning frame and drafting technology, which is applied in the field of ring spinning frames, can solve the problems of unsatisfactory properties of textile yarns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

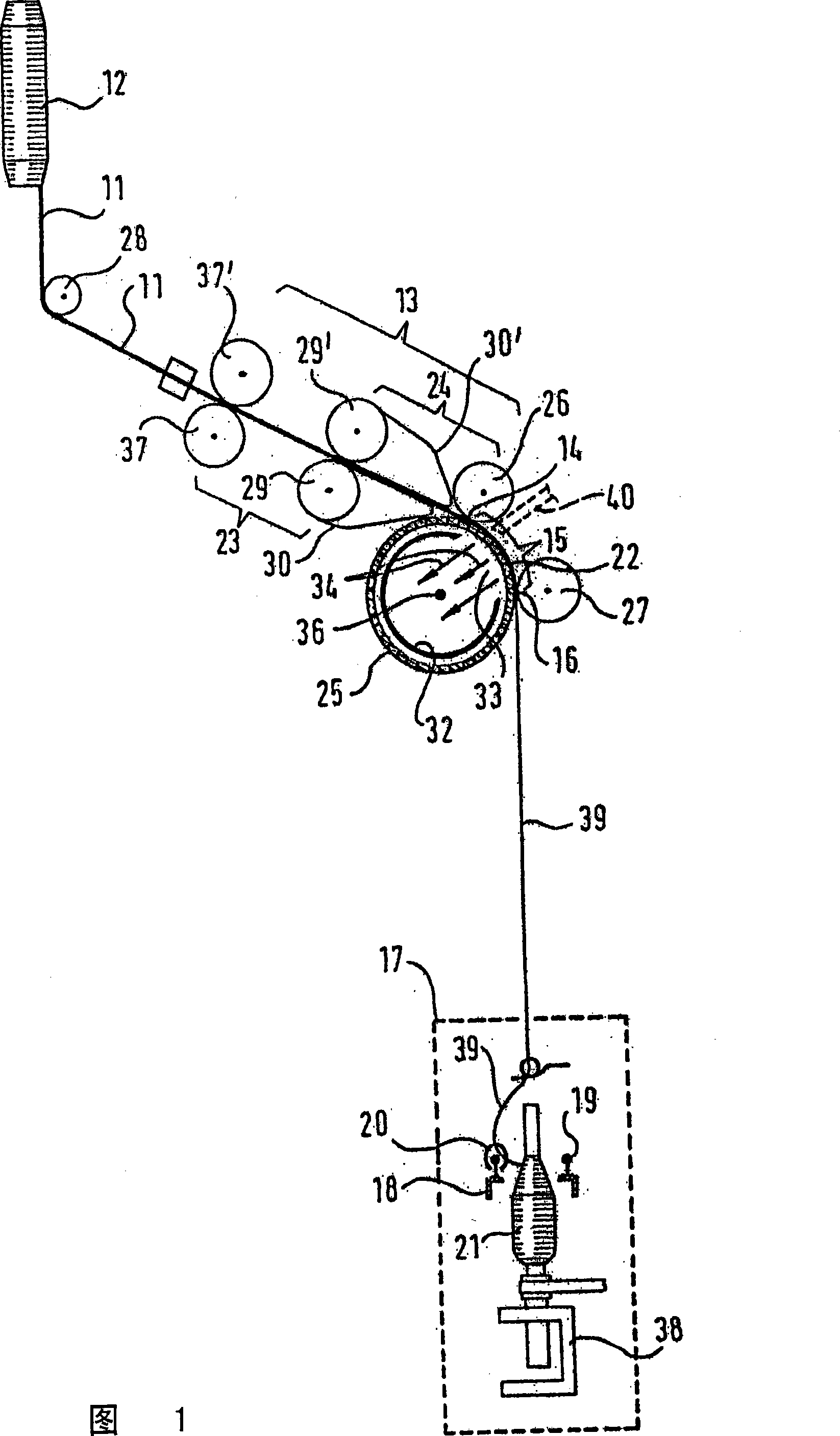

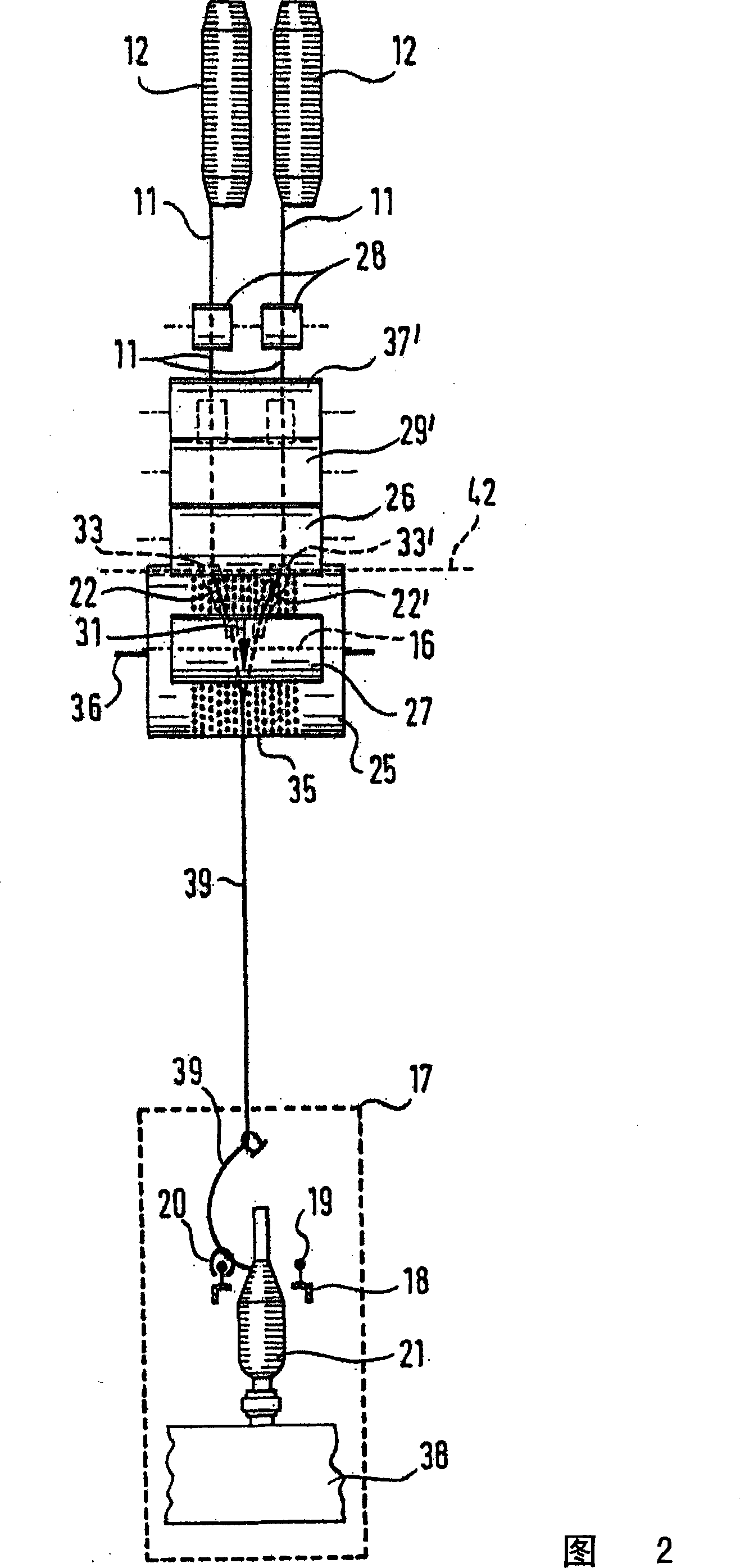

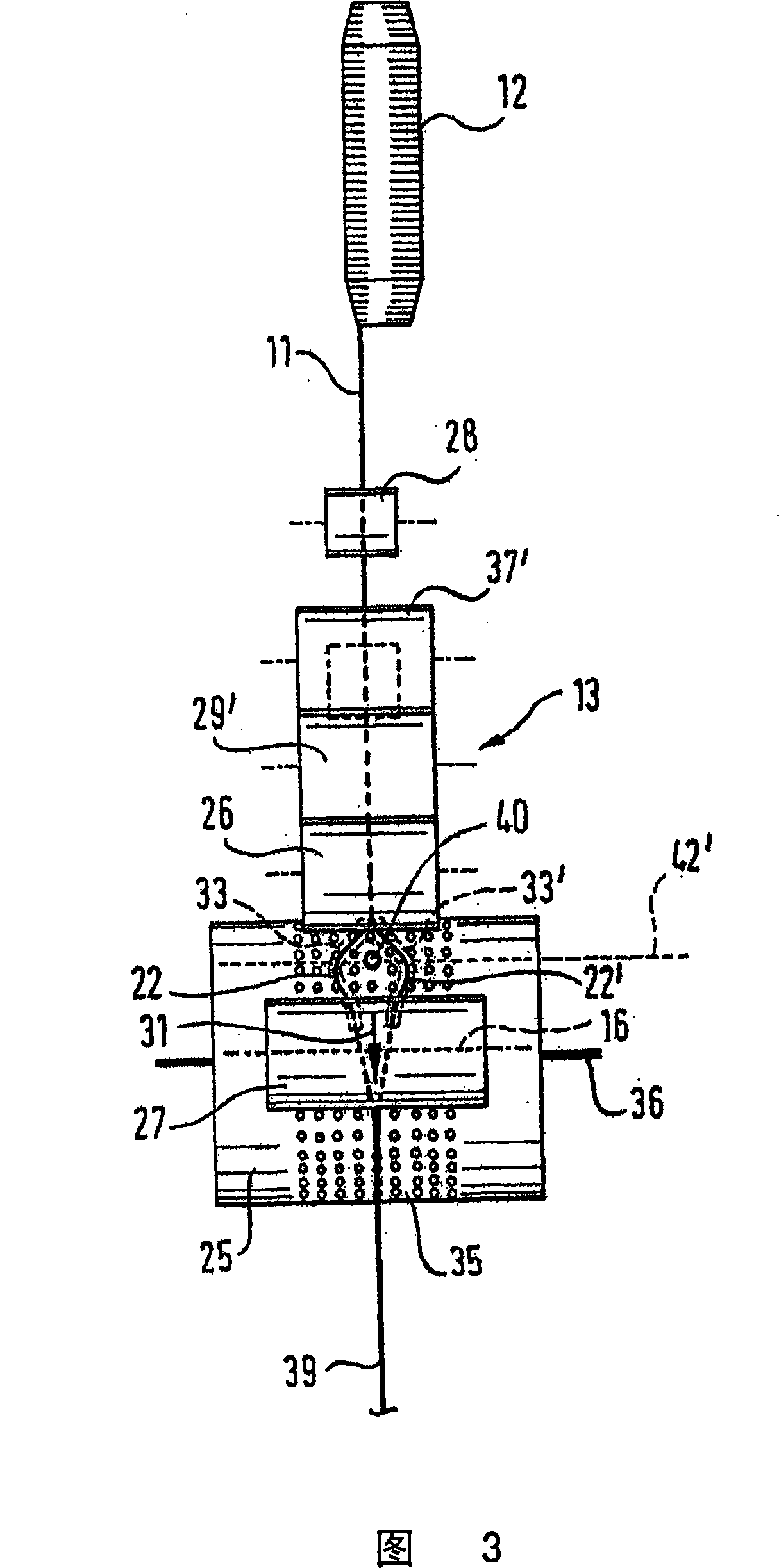

[0022] According to a particular embodiment of the invention, it relates to a spinning frame, in particular a ring spinning frame, which has at least one multistage drafting unit 13 with pairs of rollers 29, and consists of one or two roving bobbins 12 Or one or two bar cans supply fiber bundles, at its pair of outlet rollers 25,26 place or at its pair of outlet rollers 25,26 nears arrange a suction device 25, have the perforated area 35 that spreads over its circumference above, It (suction device), along a path segment 15, on its circumference, moves together with one or more fiber bundles, creating a guiding surface for these fiber bundles, so as to constitute a coagulation stage, in which At least one fibrous web comprising the final draft, but at least not yet substantially twisted or not fully twisted, is coalesced and / or bundled into compact fiber bundles 22, 22' preferably less than 1 mm wide, whereby along The path section 15 moving therewith, directly radially within...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com