Beam type tridirectional vibration separator

A vibration isolator and beam-type technology, applied in the field of vibration control of electromechanical equipment, can solve the problems of increasing the volume and quality of the vibration isolation system and increasing the manufacturing cost of the vibration isolator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

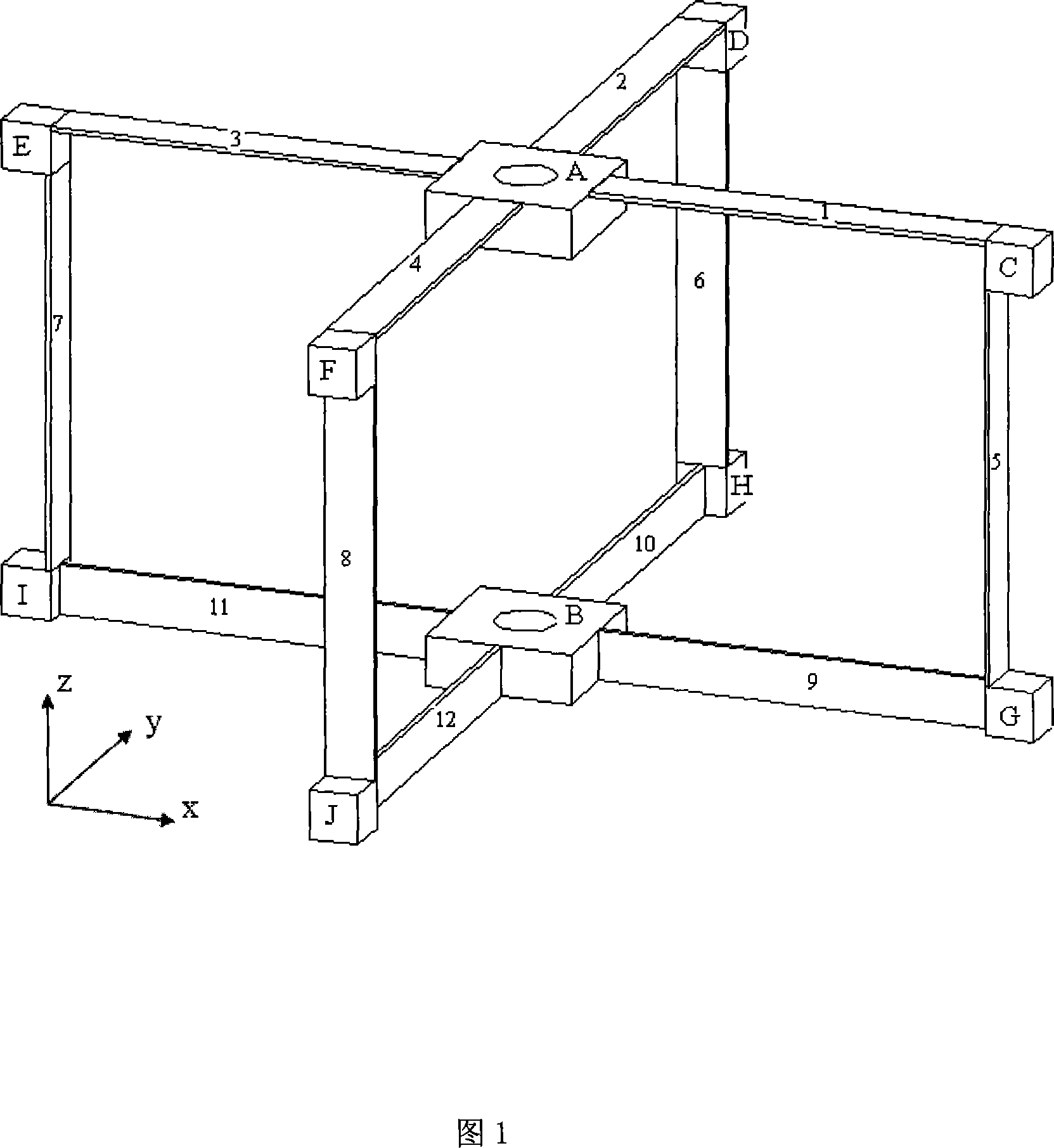

[0011] The present invention is a beam-type three-way vibration isolator, which is composed of twelve elastic beams and ten rigid blocks. According to the use environment of the vibration isolator, the beams can be made of spring steel, stainless steel or non-metallic materials with good elastic properties, and the rigid blocks are guaranteed In the case of reliable connection with the beam, a material different from the beam can be selected. The cross-section of the twelve beams must be flat and rectangular, and the cross-sectional aspect ratio can be designed according to the rigidity requirements without losing stability. The connection between the beam and the rigid block can be connected by bolts, or the two ends can be welded together with the rigid block. The lengths of the elastic beams 1, 2, 3, 4 are the same, the lengths of the elastic beams 5, 6, 7, and 8 are the same, and the lengths of the elastic beams 9, 10, 11, and 12 are the same. The space placement of the twelve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com