Method for measuring large-scale workpiece taper using ring-plane method

A technology of large workpieces and ring plates, which is applied in the field of measuring the taper of large workpieces by the ring plate method, can solve the problems of loss of accuracy, quality accidents, and low measurement accuracy, and achieve the effects of reducing construction workload, high work efficiency, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The method for measuring the taper of a large workpiece by the ring plate method comprises the following steps:

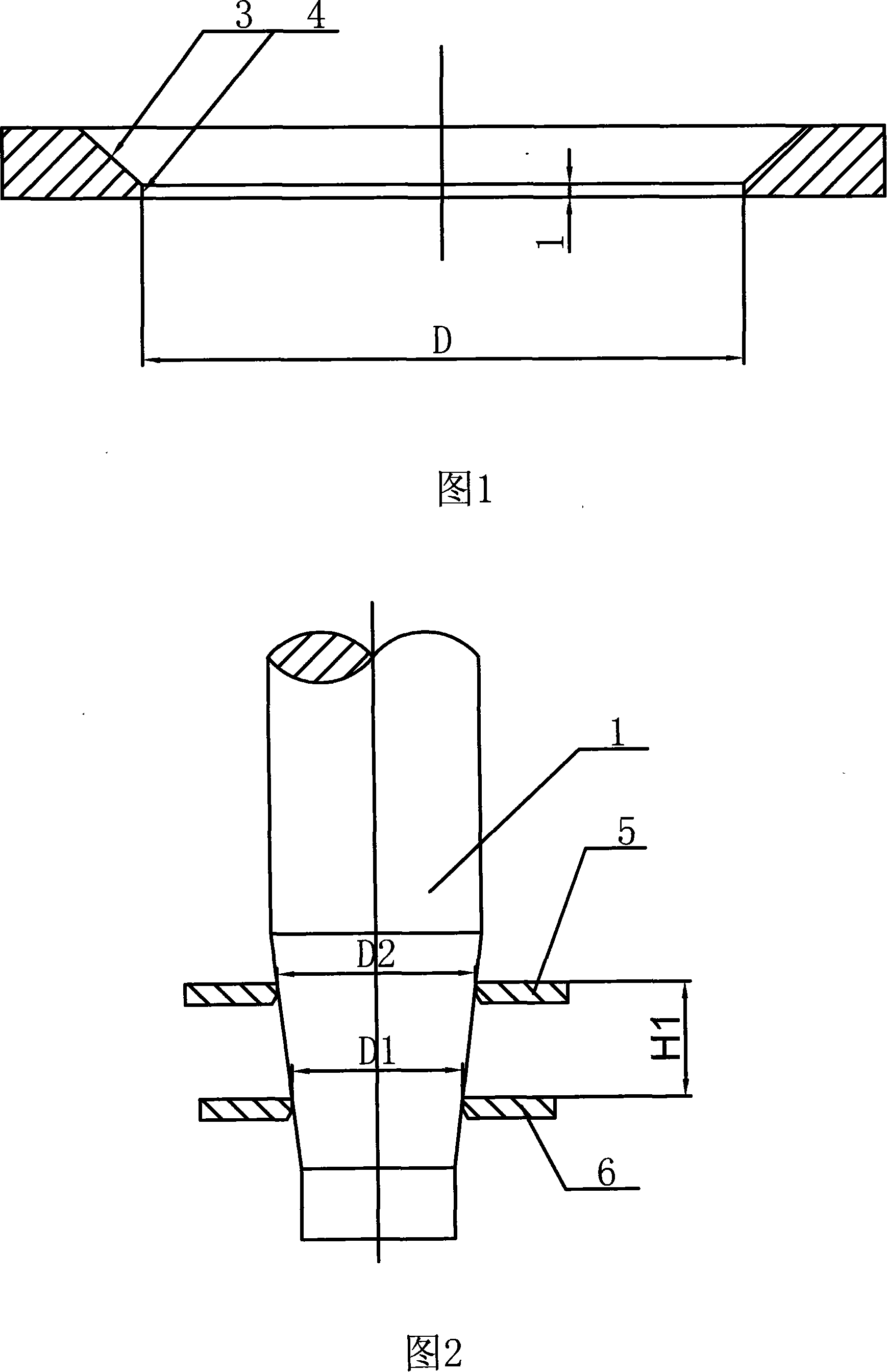

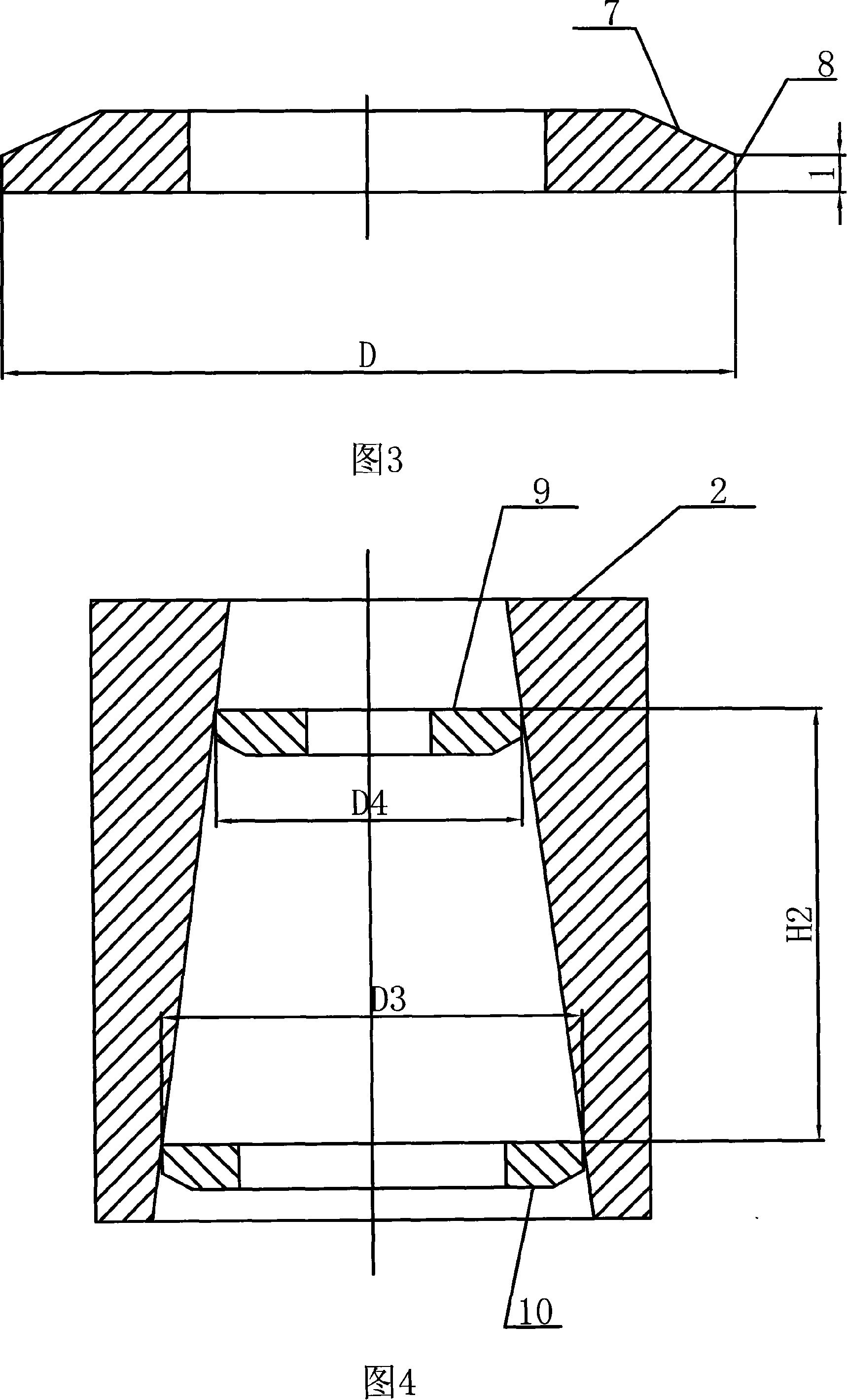

[0017] 1. According to the size of taper rod and taper hole, process and manufacture taper rod measuring large diameter ring plate 5 and taper rod measuring small diameter ring plate 6 with different diameter inner holes, and process and manufacture tapered hole measuring large ring plate 10 with different diameter outer circles and the tapered hole measuring small ring plate 9, the inner holes of the tapered rod measuring large diameter ring plate 5 and the tapered rod measuring small diameter ring plate 6 are all processed into an inner diameter platform part 4 and an inner diameter cone part 3; the inner diameter platform part 4 height 1 mm, the platform is perpendicular to the two ring surfaces, the inner diameter of the large-diameter ring plate 5 measured by the processed cone rod is smaller than the outer diameter of the large end of the measured cone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com