Method for monitoring fatigue damage using ferromagnetic materials surface stray magnetic field signal

A stray magnetic field and fatigue damage technology, applied in the size/direction of the magnetic field, material magnetic variables, magnetic properties measurement, etc., can solve the problem of no mapping relationship, and achieve the degree of fatigue damage, good repeatability, and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is realized by following measures:

[0024] The material of the tested component is 18CrNiWAVA steel, and the metal magnetic memory testing instrument is EMS-2003.

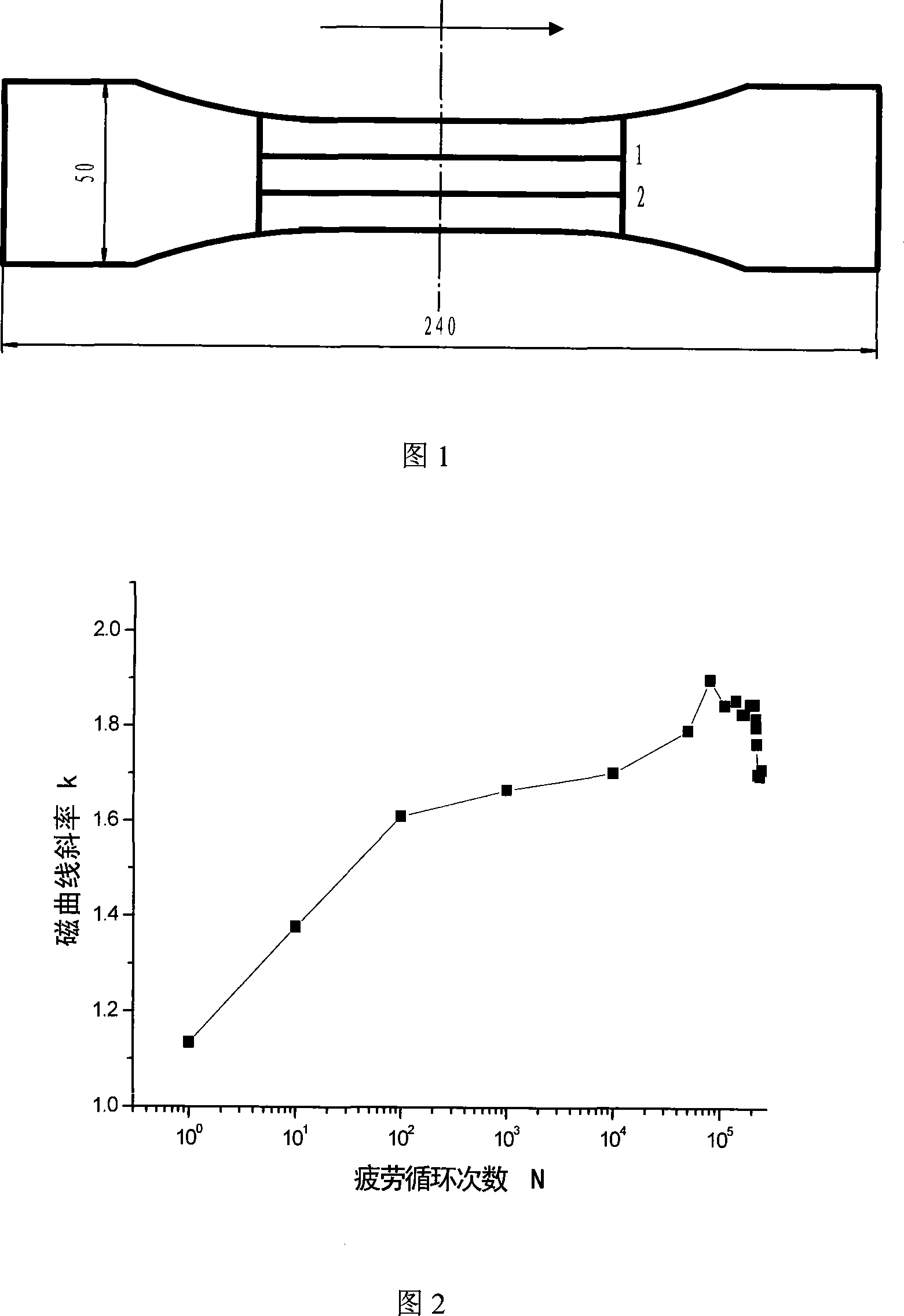

[0025] First of all, the ferromagnetic material 18CrNiWAVA steel, which is the same as the material of the tested component, is selected, and the plate-shaped smooth fatigue test piece is made according to the national standard. Carry out final heat treatment on the standard sample according to the heat treatment specification of the tested component, in a vacuum of 8×10 -1 Heat it to 860°C in Pa WZC-30 type vacuum heat treatment furnace, keep it warm for 30 minutes, oil quench, then temper at 180°C, and water cool to room temperature to obtain a pure initial magnetic state.

[0026] Secondly, mark two parallel detection lines on the surface of the test piece with a length of 240mm, the length of the detection line is 100mm, and the vertical distance between the two lines is 10mm, as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com