Improvements in or relating to hydraulic rams

A technology of blowout preventer and ram, which is applied in wellbore/well components, sealing/isolation, earthwork drilling and production, etc. It can solve problems such as difficult configuration, heavy seabed blowout preventer or closing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

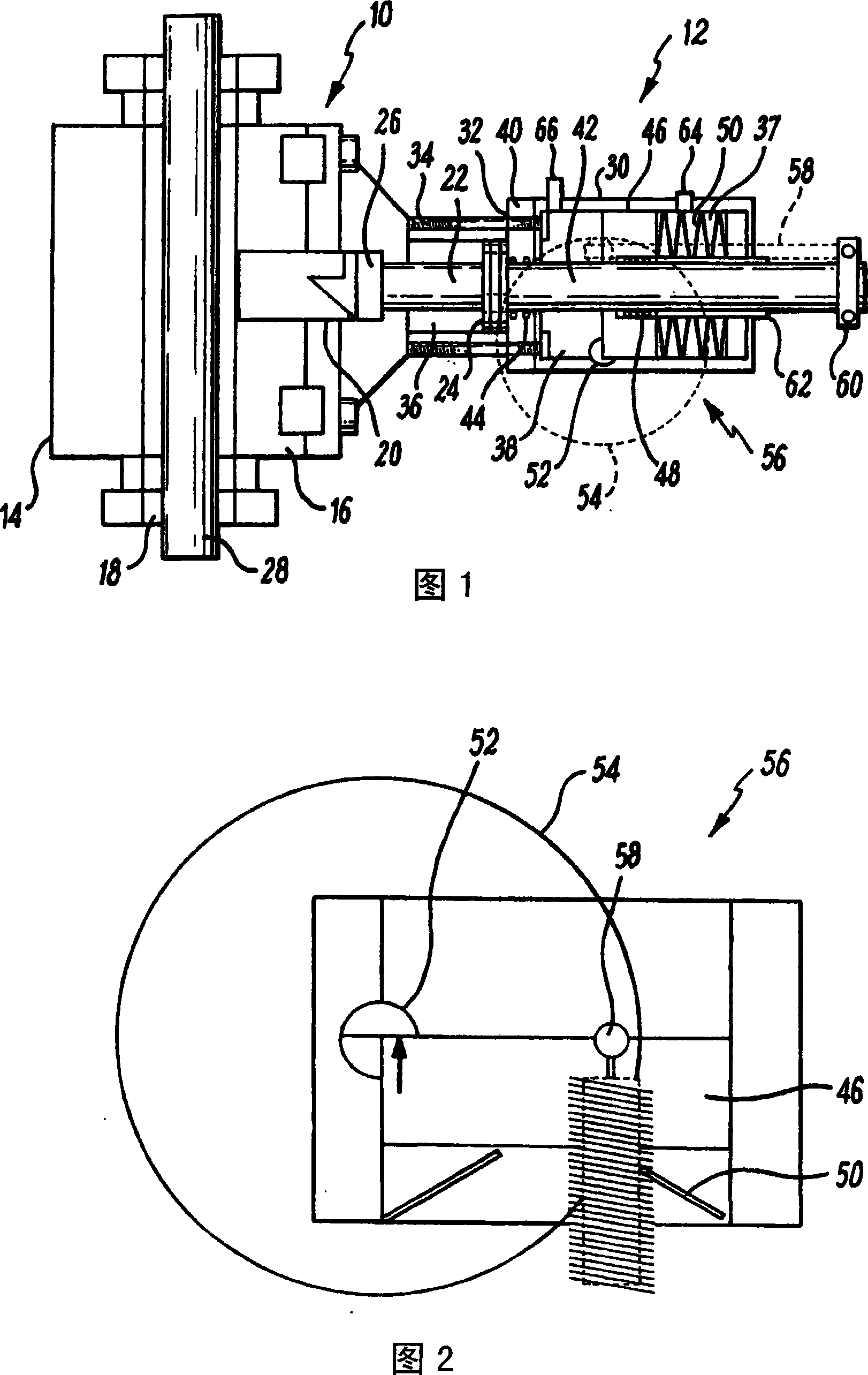

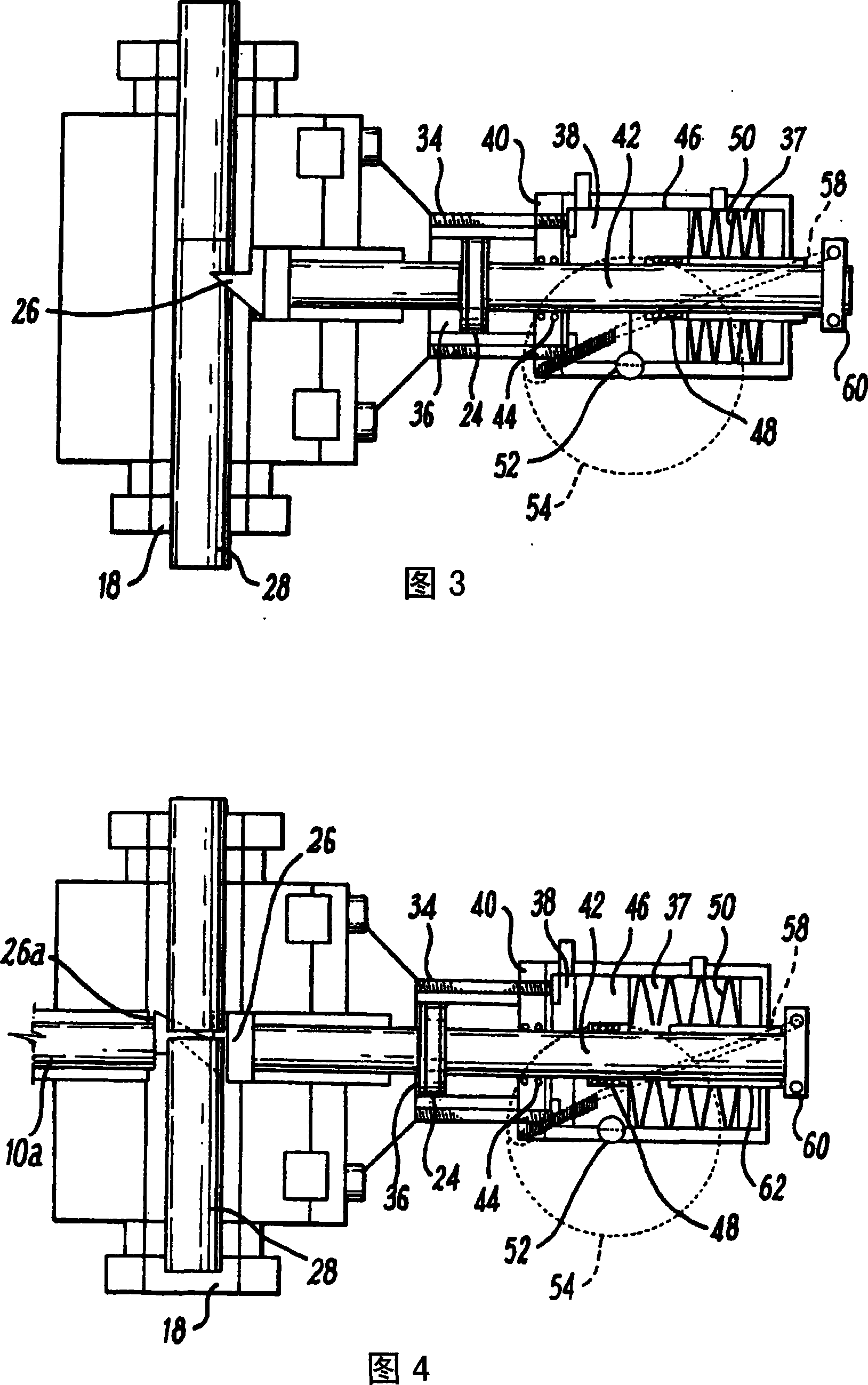

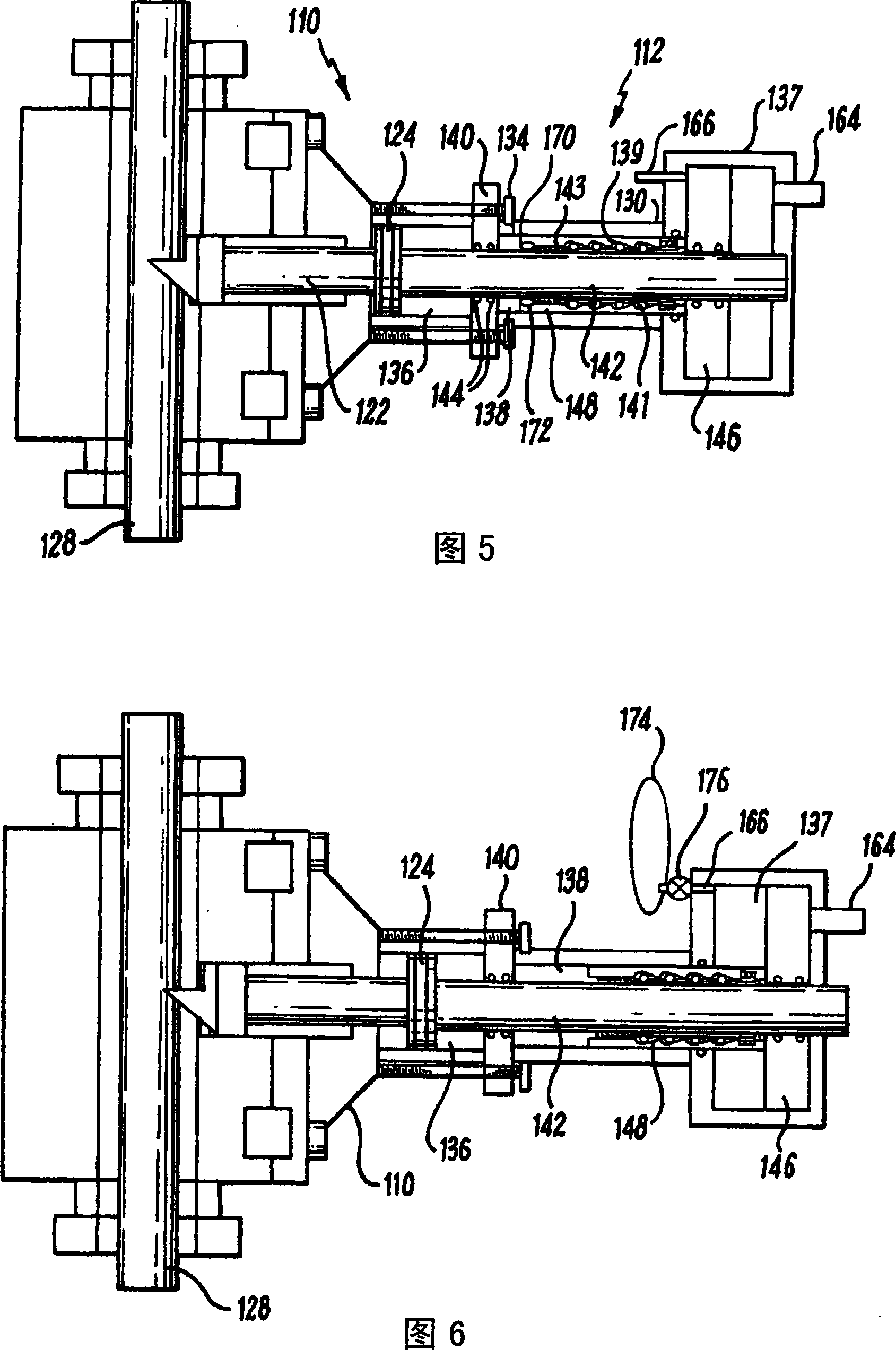

[0046] According to a first embodiment of the invention, reference numbers are first set in Figure 1 of the accompanying drawings showing a hydraulic blowout preventer ram generally indicated by reference numeral 10, auxiliary force actuator 12 is installed on the hydraulic blowout preventer ram.

[0047] Hydraulic BOP ram 10 is part of BOP 14 . The blowout preventer 14 includes a body 16 having an axial bore 18 therethrough and at least one transverse port 20 entering the bore 18 . The hydraulic BOP ram 10 is mounted at the transverse port 20 . The BOP ram 10 includes a cylindrical shaft 22 having a piston 24 at a first end and a shear blade 26 mounted at an opposite end. The piston operates in the BOP ram chamber 36 by pressurization of hydraulic fluid behind the piston 24 .

[0048] Drill rod or tubular 28 is positioned through bore 18 as is conventional. In the event of a blowout, the piston 24 is actuated to force the shaft 22 towards the bore 18 . Typically, two opp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com