Holweck vacuum pump

A technology of vacuum pumps and rotors, which is applied in the direction of pumps, pump components, axial flow pumps, etc., and can solve problems such as reducing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

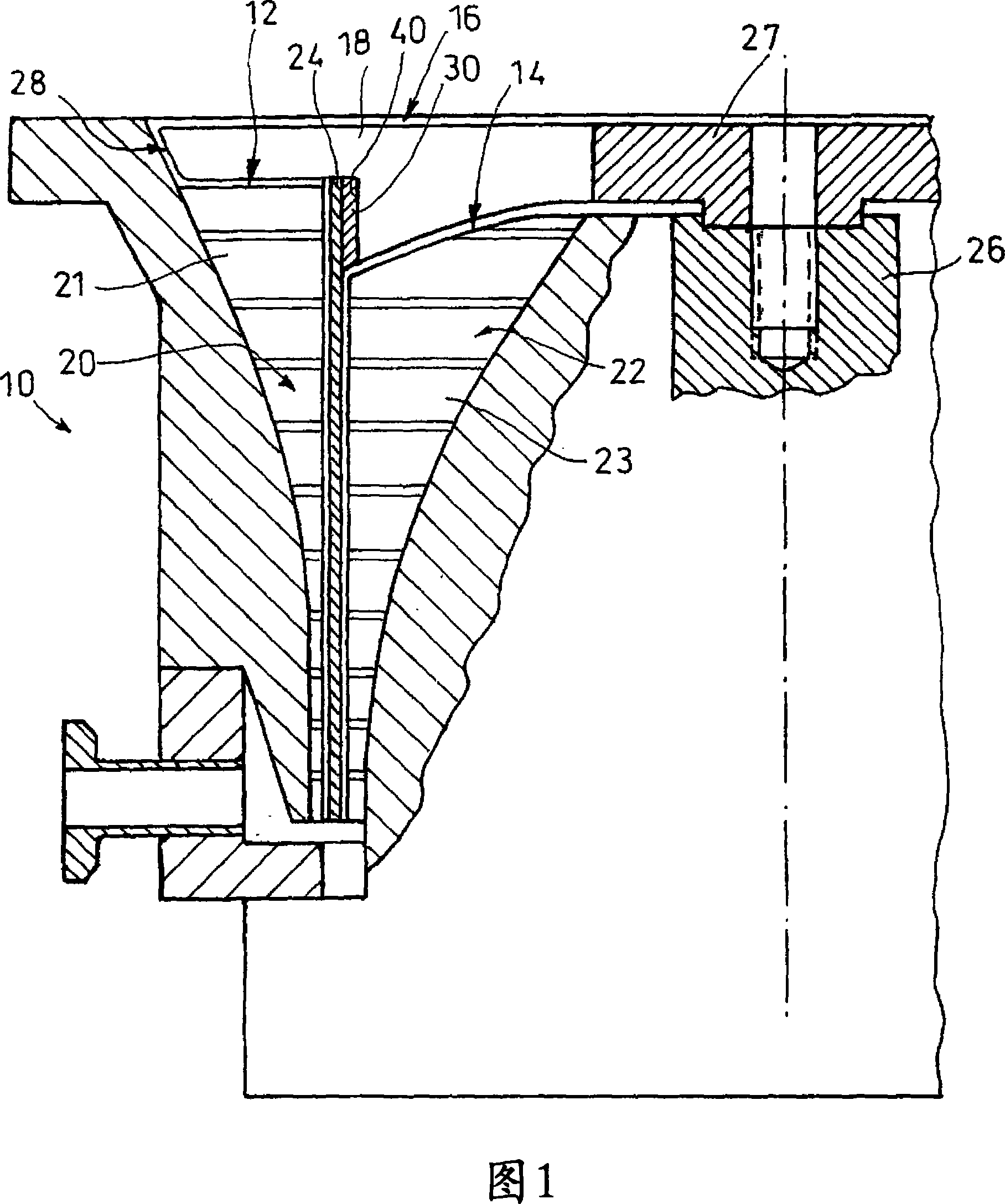

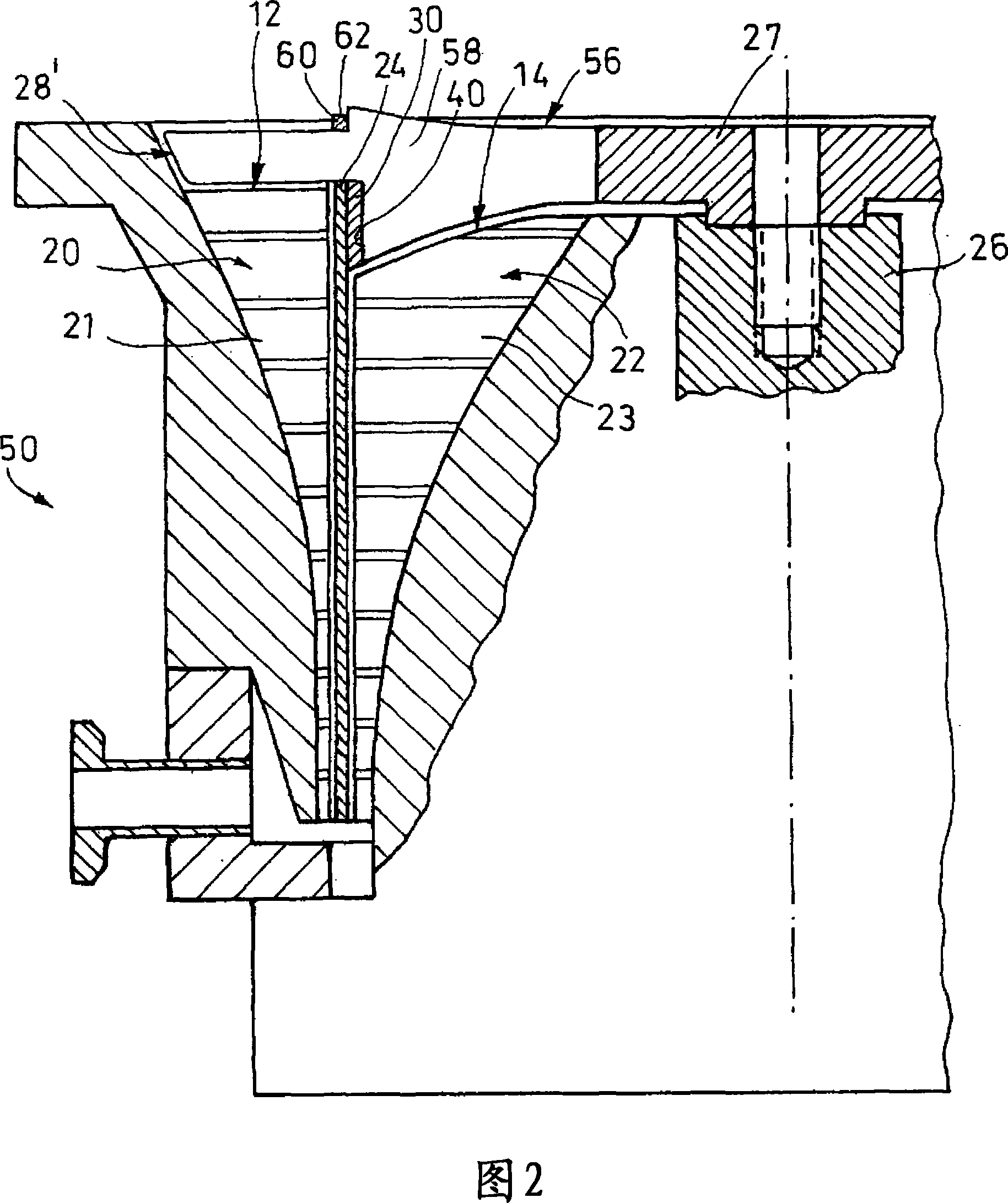

[0014] Figures 1 and 2 show Holwick vacuum pumps 10, 50 comprising two parallel Holwick pump stages 12, 14, respectively. On the inlet side, the two Holwick vacuum pumps 10, 50 include rotor impellers 28, 28', respectively, and the rotor impellers 28, 28' have a plurality of blades 18, 58, respectively.

[0015] The two Hallwick pump stages 12, 14 are basically composed of a radially outer pump stator 20, a radially inner pump stator 22, and a rotor tube 24 arranged between the two stators 20, 22, respectively. The inner and outer pump stators 20, 22 respectively include spiral thread grooves 21, 23, and the groove bottoms of the spiral thread grooves 21, 23 respectively taper radially toward the outlet.

[0016] The pump rotor 16 basically includes a shaft 26, a hub 27, a blade 18, a support ring 30, and a rotor tube 24, and the shaft 26 is supported by a rolling bearing and / or a magnetic bearing. The pump rotor 56 of the vacuum pump 50 shown in FIG. 2 further includes a second g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com