Damping device for an output shaft in a gearbox

The technology of a shock absorbing device and a gear box is applied in the direction of supporting devices, drilling equipment, drilling equipment and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

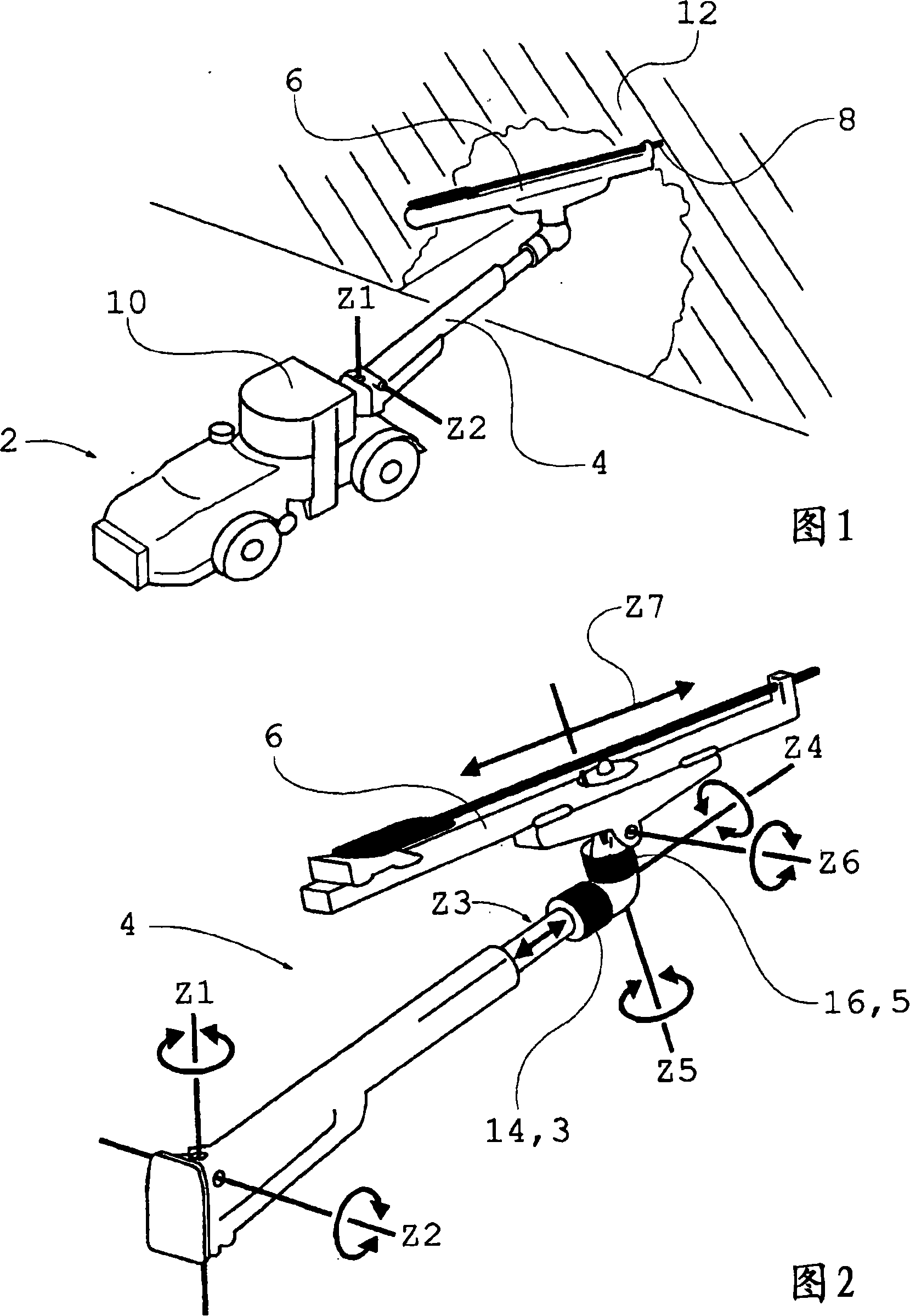

[0013] FIG. 1 shows a schematic view of a rock drilling rig 2 comprising a boom 4 , a thruster 6 and a cutting head 8 . The rock drilling rig 2 can be remotely controlled by an operator via a cable (not shown) or by wireless means, but can also be controlled by an operator located in an operating cabin 10 on the rock drilling rig 2 . The operator can control the rock drilling machine 2 manually, automatically or semi-automatically. When an operator wants to use the rock drill 2 to drill a hole in rock 12, it is important that the cutting head 8 of the pusher 6 can be positioned in the correct position and in the correct angular orientation relative to the rock 12 in order to produce the desired hole , especially when several holes are to be drilled into the rock 12 parallel to each other, such as occurs when drilling a tunnel through a mountain.

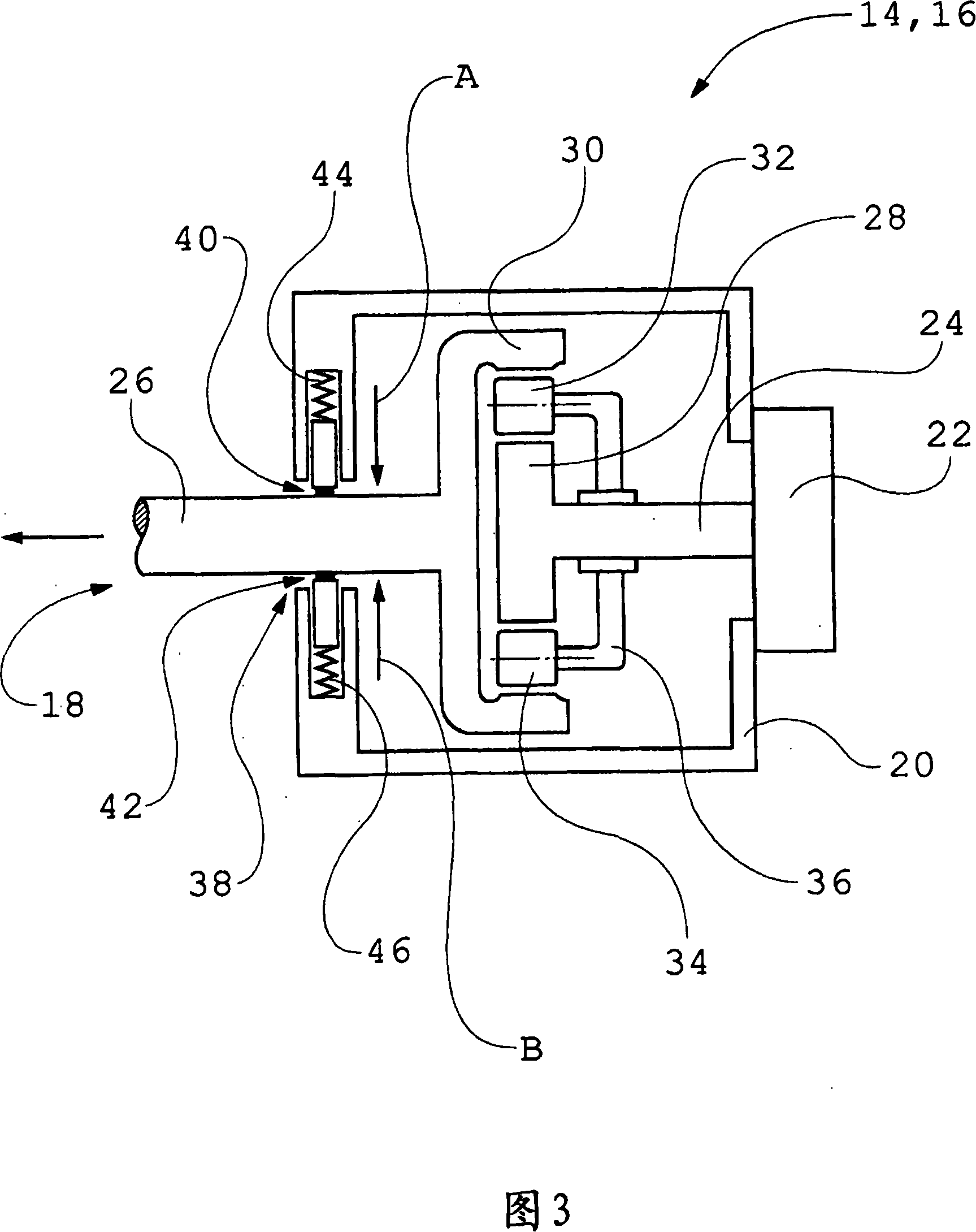

[0014] FIG. 2 shows a schematic diagram of the drill boom 4 on the rock drilling machine 2 in FIG. 1 . According to this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com