Stationary vibration distributary screen

A technology of vibrating screen and fixed screen, applied in solid separation, filtering screen, separating solid from solid by air flow, etc., can solve the problems of large friction coefficient, large convection flow, large particle size difference, etc., and achieve long service life. , compact structure, high screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

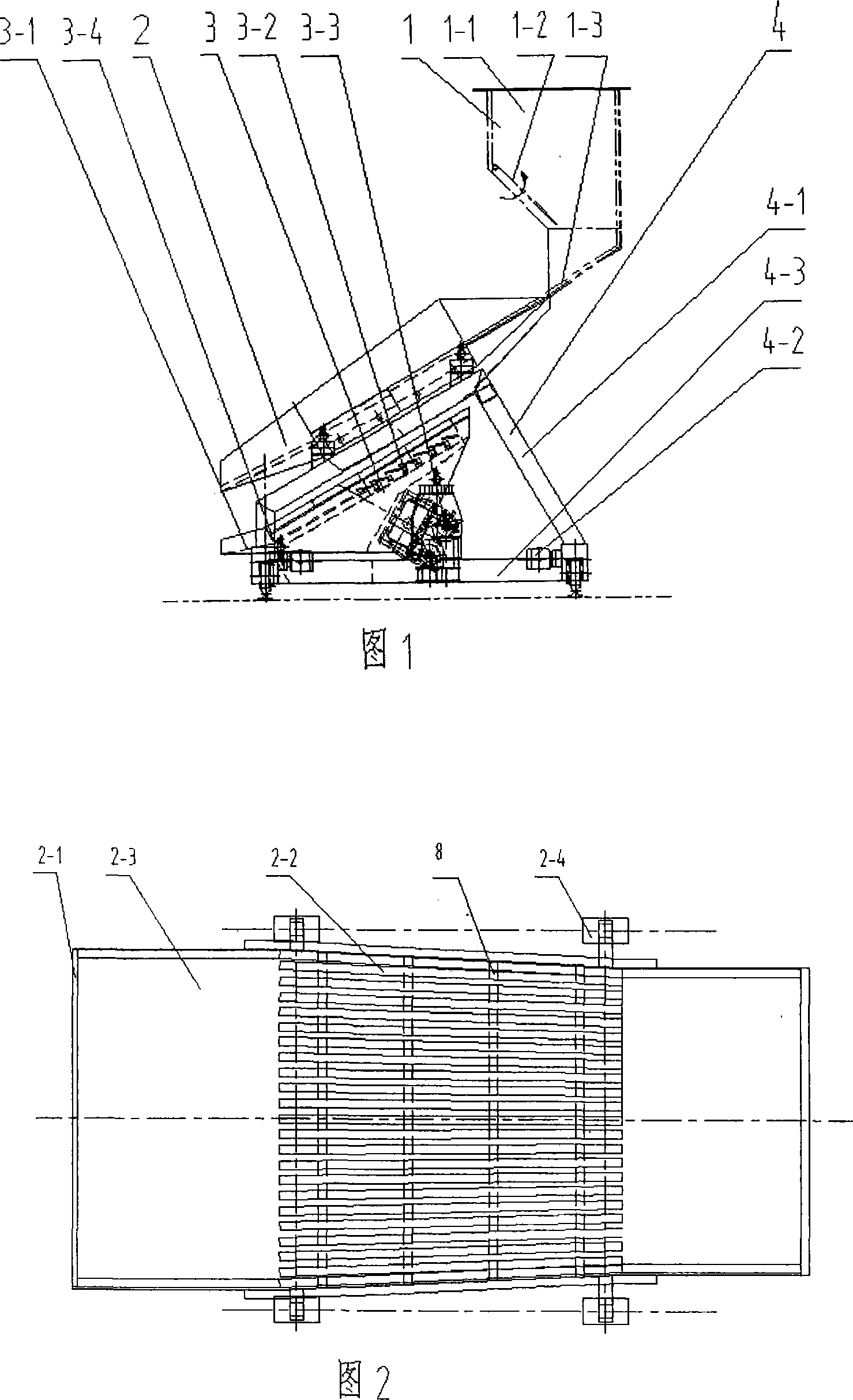

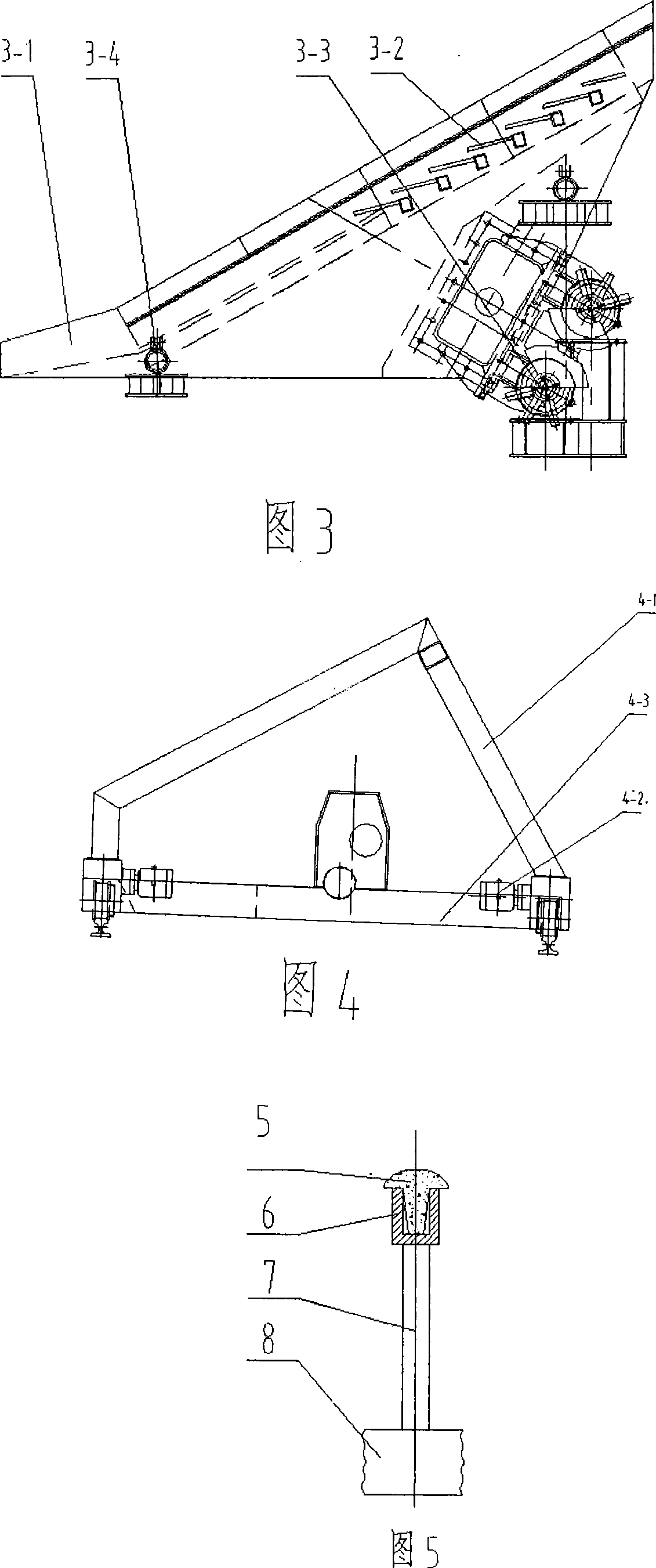

[0007] In the present invention, a gate 1 is arranged on the guide chute 1-1 above the fixed screen 2. When the material enters the fixed screen through the gate, it can be opened by the gate 1-2 provided on the guide chute and its liner 1-3. Control the amount of material added. Because the inclination angle of the fixed screen surface can be adjusted by adjusting the support 2-4, to improve the screening efficiency. Because the wear-resistant cast stone liner 2-3 is set on the screen surface of the fixed sieve, and the screen bars are replaced with cast stone bars 2-2 simultaneously, the service life of the equipment can be effectively extended. The specific structure of the cast stone screen bar is shown in Figure 5. Each cast stone screen bar is fixed in a U-shaped groove 6 with an adhesive, and the U-shaped groove is made of stainless steel. Each U-shaped groove is fixed on the beam 8 Connected support 7. At the same time, the gap between the sieve bars is made into a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com