Screen apparatus

A screening device, vibrating screen technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of blockage at the entrance of coal bunker, outage of main shaft belt conveyor, threatening the life safety of staff, etc. The effect of shipping and damage, increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

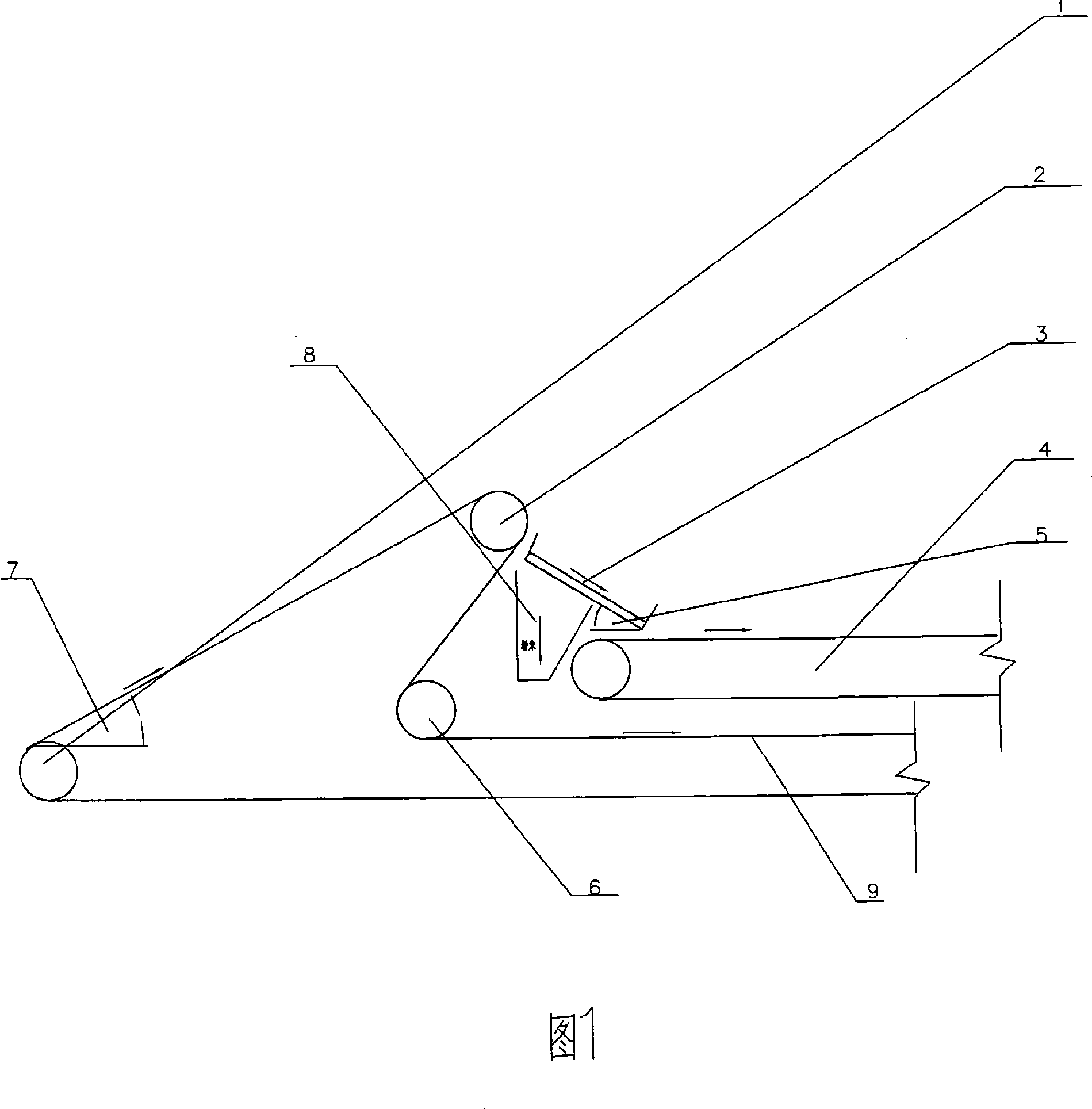

[0009] The screening device includes the tail drum 1, the transfer drum 2, the vibrating screen 3, the gangue picking belt conveyor 4, the redirecting drum 6, the chute 8. The tail drum 1 and the redirecting drum 6 and the transfer drum 2 form a belt conveyor. In the tail section of the machine, a vibrating screen 3 is installed below the transfer drum 2, a chute 8 is installed directly below the vibrating screen 3, and a gangue picking belt conveyor 4 is installed below the end. The belt formed by the tail drum 1 and the transfer drum 2 is horizontal The included angle is 7, the included angle is 8 degrees, the vibrating screen 3 and the horizontal, the included angle is 5, and the included angle is 6 degrees. The raw coal containing gangue (the lower group of coal) is discharged from the top of the transfer drum 2 into the vibrating screen 3, after the vibrating screen 3 works, the large pieces of raw coal and gangue flow into the gangue sorting belt 4, and the large pieces of g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com