Pneumatic motor

An air motor and cylinder technology, which is applied to machines/engines, rotary piston engines, fluid pressure actuating devices, etc., can solve the problems of difficulty in production and processing, large volume and weight of air motors, and bulky equipment, and achieves a lightweight, compact appearance. Weight and volume reduction, flexible handling and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

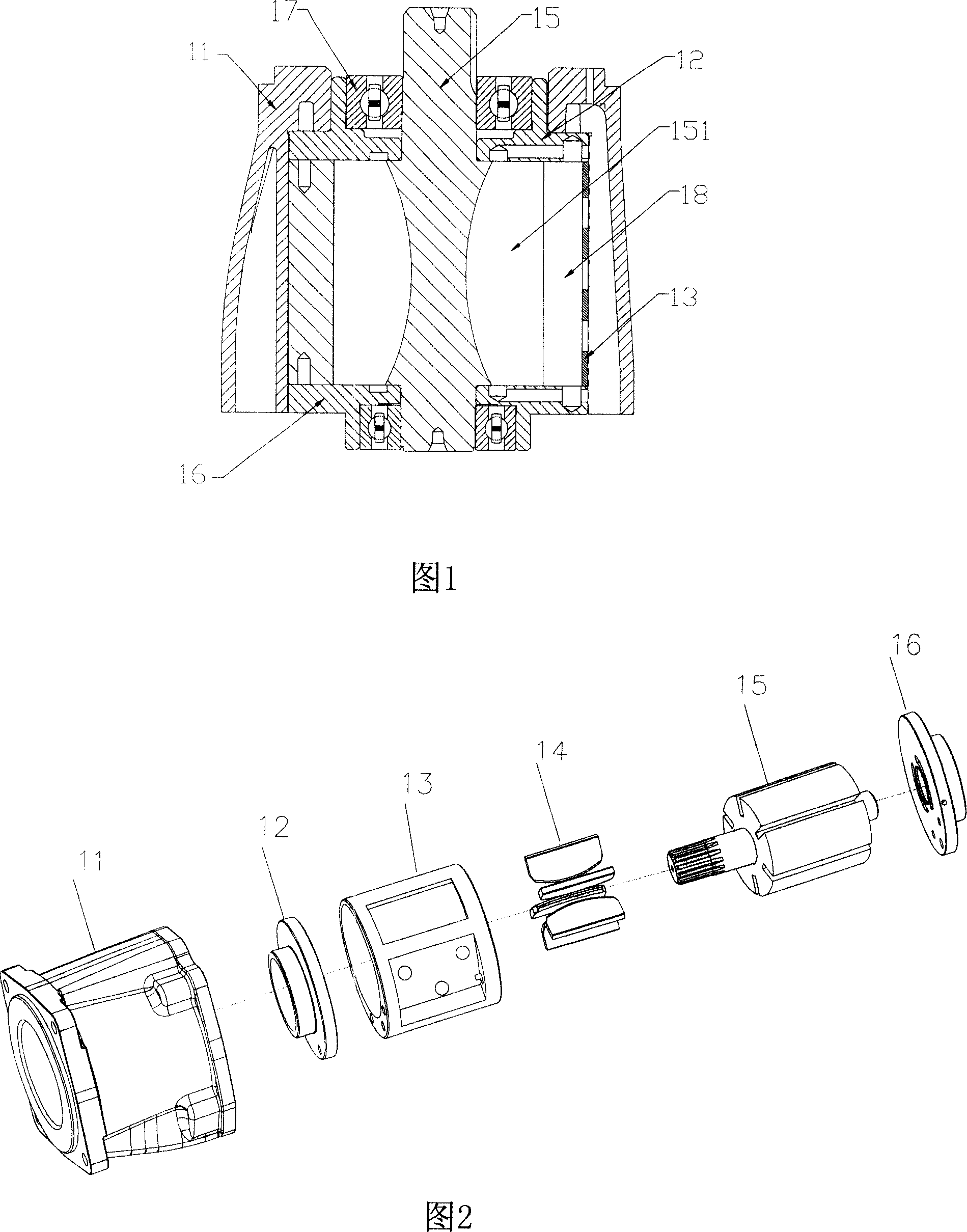

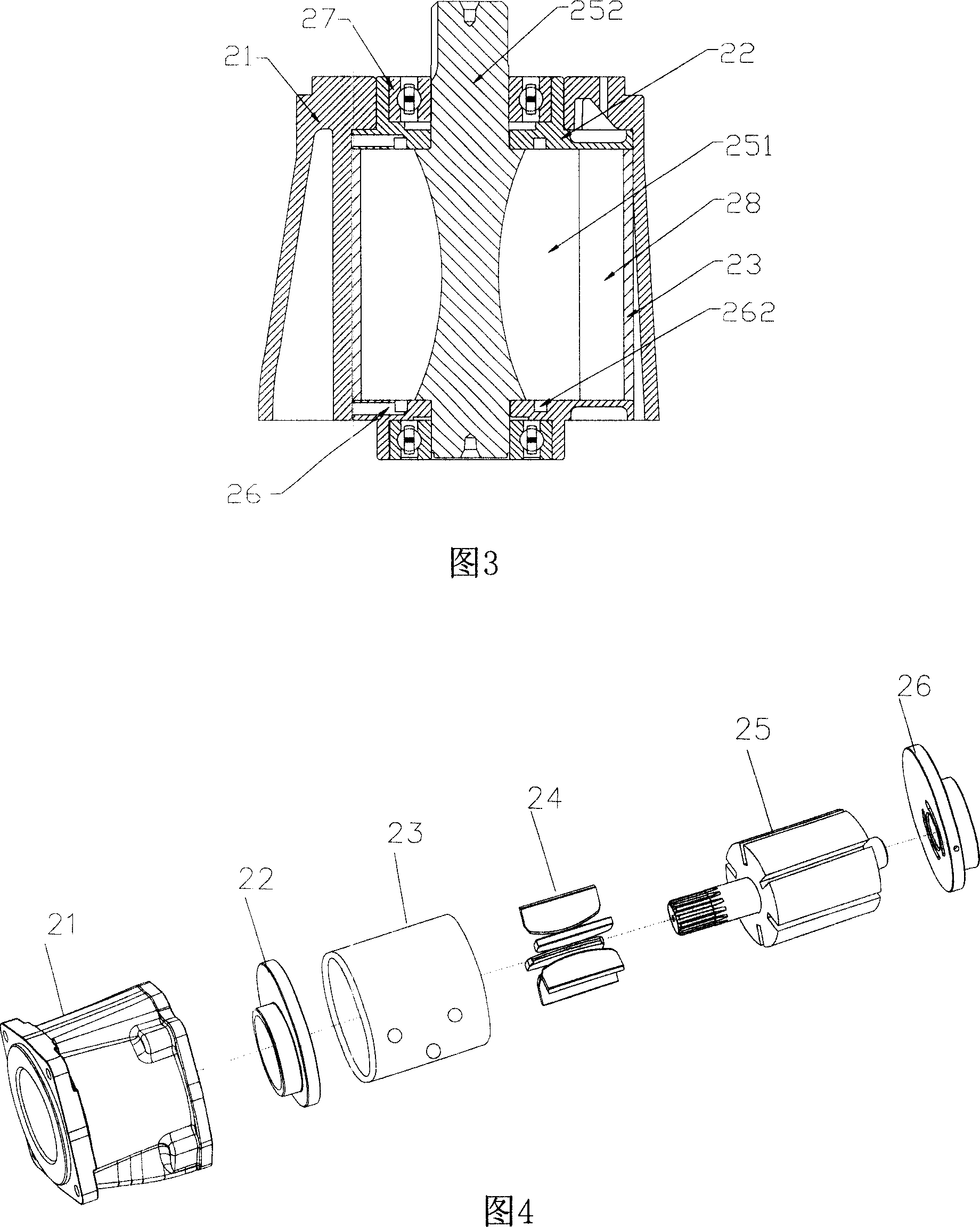

[0021] As shown in Figures 3, 4, and 6, it is a preferred embodiment of the present invention, including a main body 21 and a cylinder lower seat 22, a cylinder 23, blades 24, a pneumatic rotor 25 and an upper cylinder seat 26 installed in the main body 21, The cylinder lower seat 22 and the cylinder upper seat 26 are fixed at both ends of the cylinder 23, the pneumatic rotor 25 is placed therein, and the pneumatic rotor 25 is provided with blade grooves 251 for inserting the blades 24. Two bearings 27 are respectively arranged in the cylinder lower seat 22 and the cylinder upper seat 26 for fixing the rotor shaft 252 of the pneumatic rotor 25 .

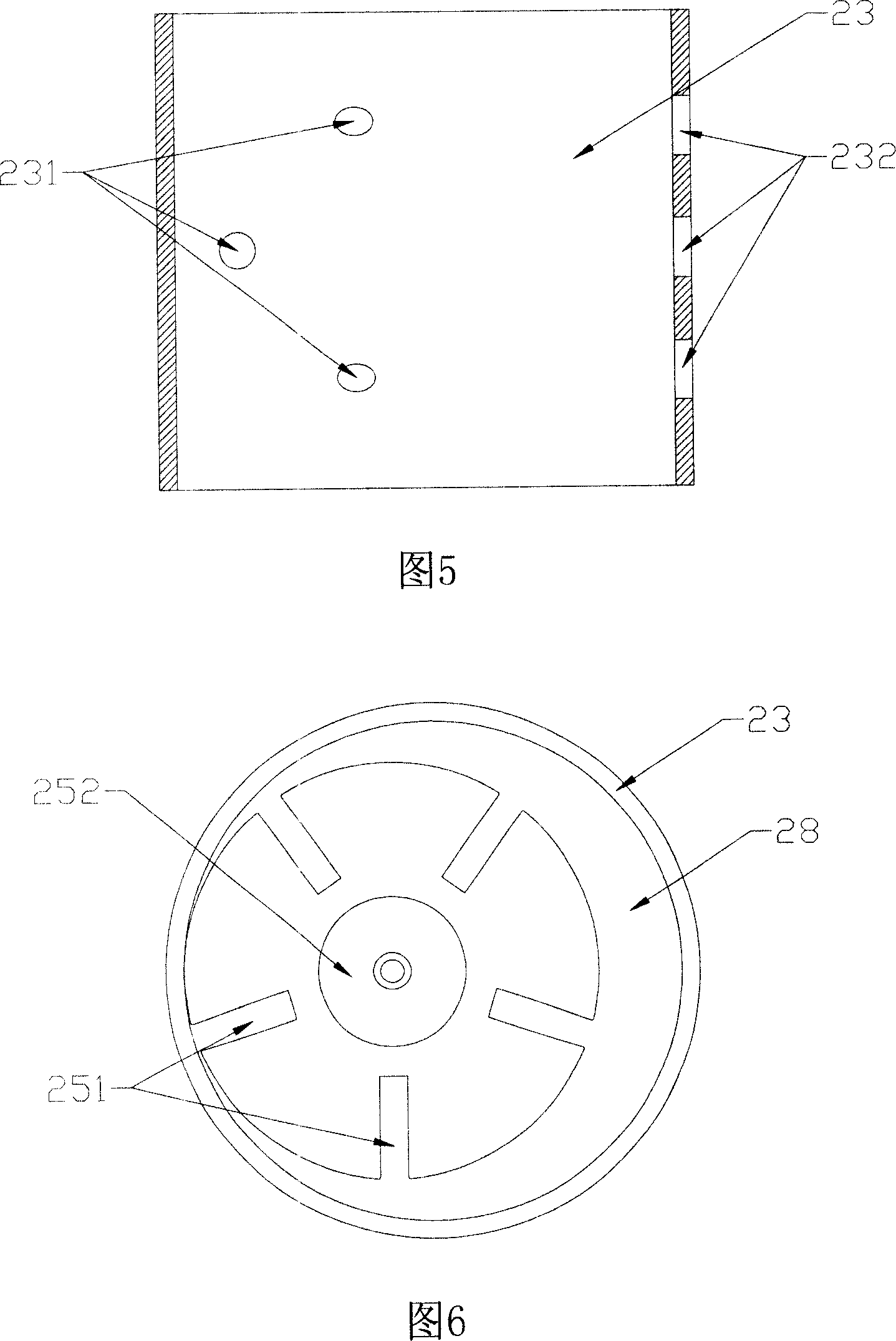

[0022] Described cylinder 23 as shown in Figure 5, outer circumference and inner circumference are concentric, make the wall thickness of whole cylinder wall the same, in order to guarantee enough air gap is left between described cylinder and pneumatic rotor, described cylinder lower seat 22 The inner circumference of the bearing on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com