Angular position inductive sensor

A sensor and inductive technology, applied in the direction of converting sensor output, instruments, and using electric/magnetic devices to transfer sensing components, etc., can solve problems such as high cost and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

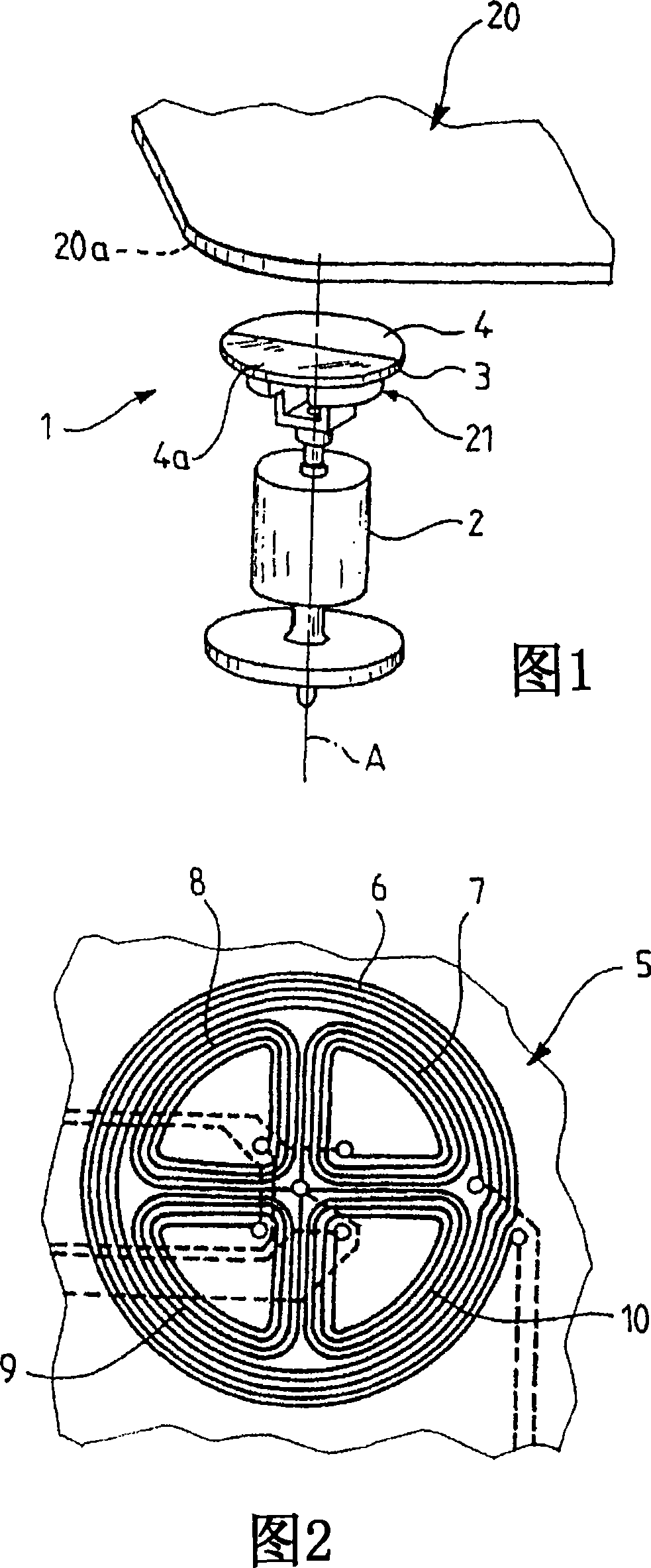

[0026] Referring to FIG. 1 , there is shown a rotary mobile body 2 which is driven to rotate about its axis of rotation A by, for example, a flow of liquid (not shown). The inductive angle sensor 1 includes a stator 20 and a rotor 21 . The stator 20 and the rotor 21 are angularly movable along the axis A relative to each other. It should be noted that the use of the term stator does not imply that the stator 20 has a fixed orientation.

[0027] The rotor 21 includes a rotating disk 3 . The rotary disk 3 is arranged on the rotary moving body 2 so that the rotary disk 3 as a whole rotates along the axis A of the rotary moving body 2 . The flat surface 4 of the disk 3 opposite the rotationally mobile body 2 is partially metallized. For example, half the disc 4a is metallized.

[0028] The stator 20 includes a printed circuit 5 (Fig. 2). The printed circuit 5 is arranged on the right next to the disc 3 and substantially parallel to the surface 4 .

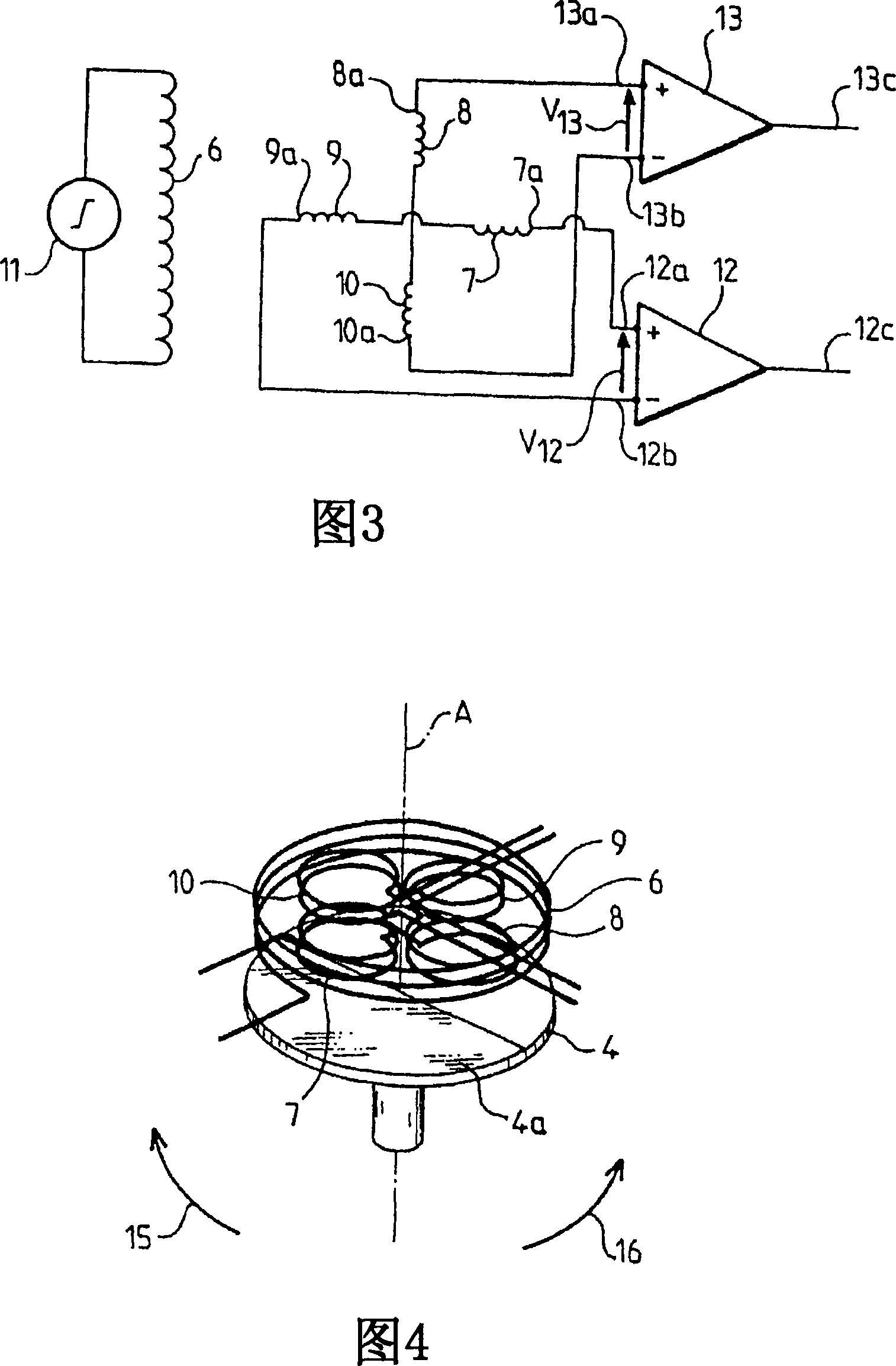

[0029] Referring to Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com