Combined harvester

A technology of combine harvester and harvesting section, applied in the direction of harvester, cutter, agricultural machinery and implements, etc., can solve the problem of heavy opening and closing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

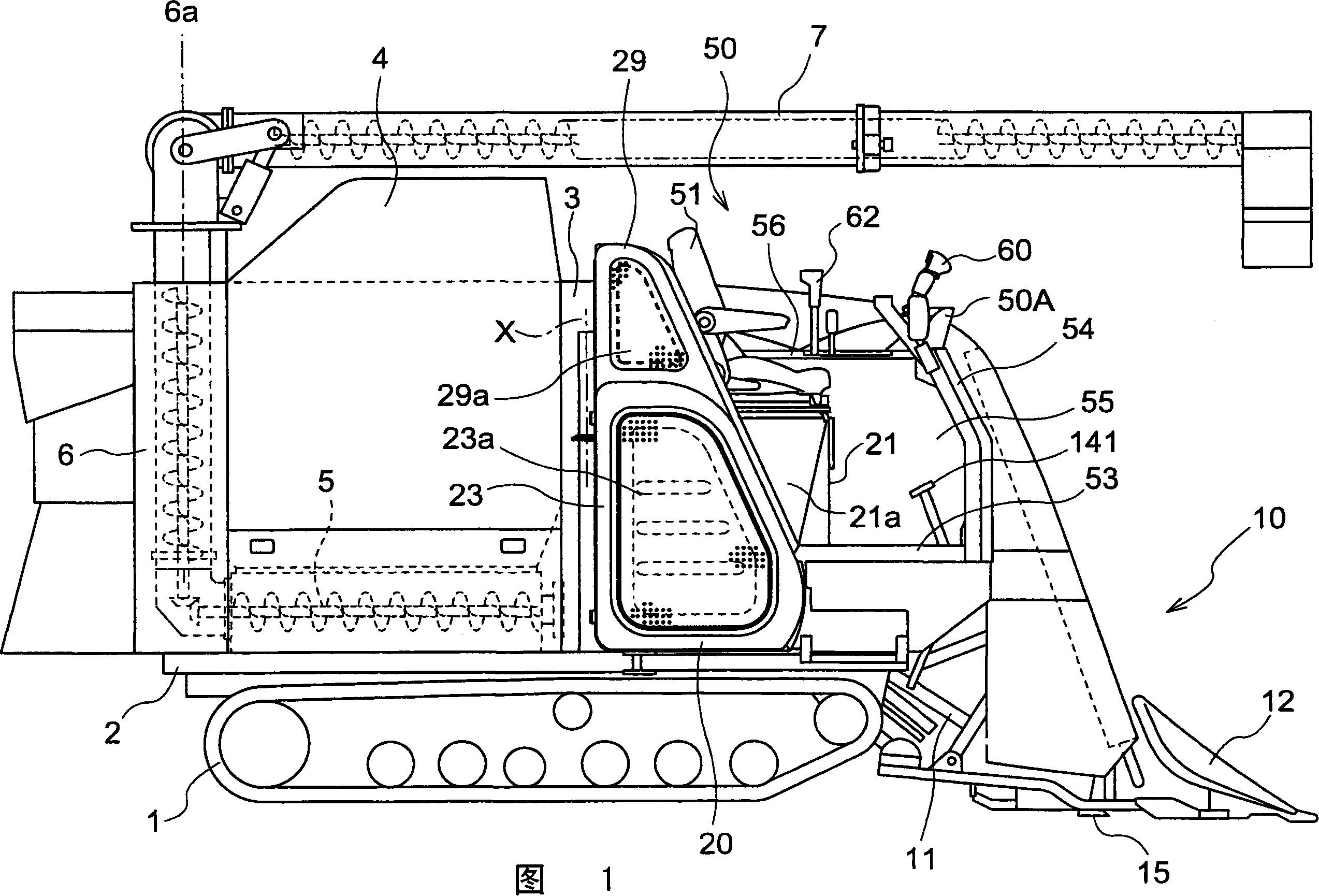

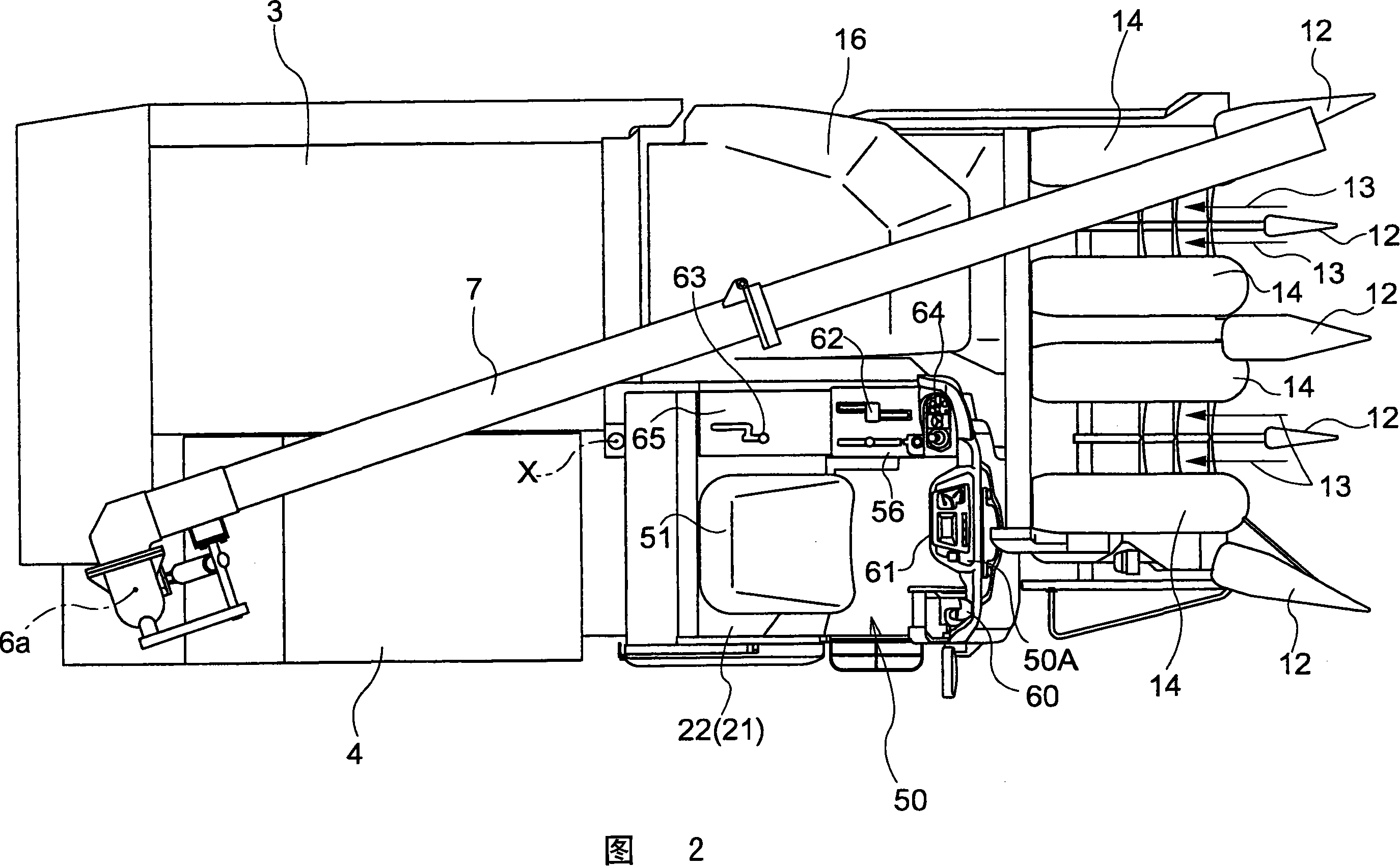

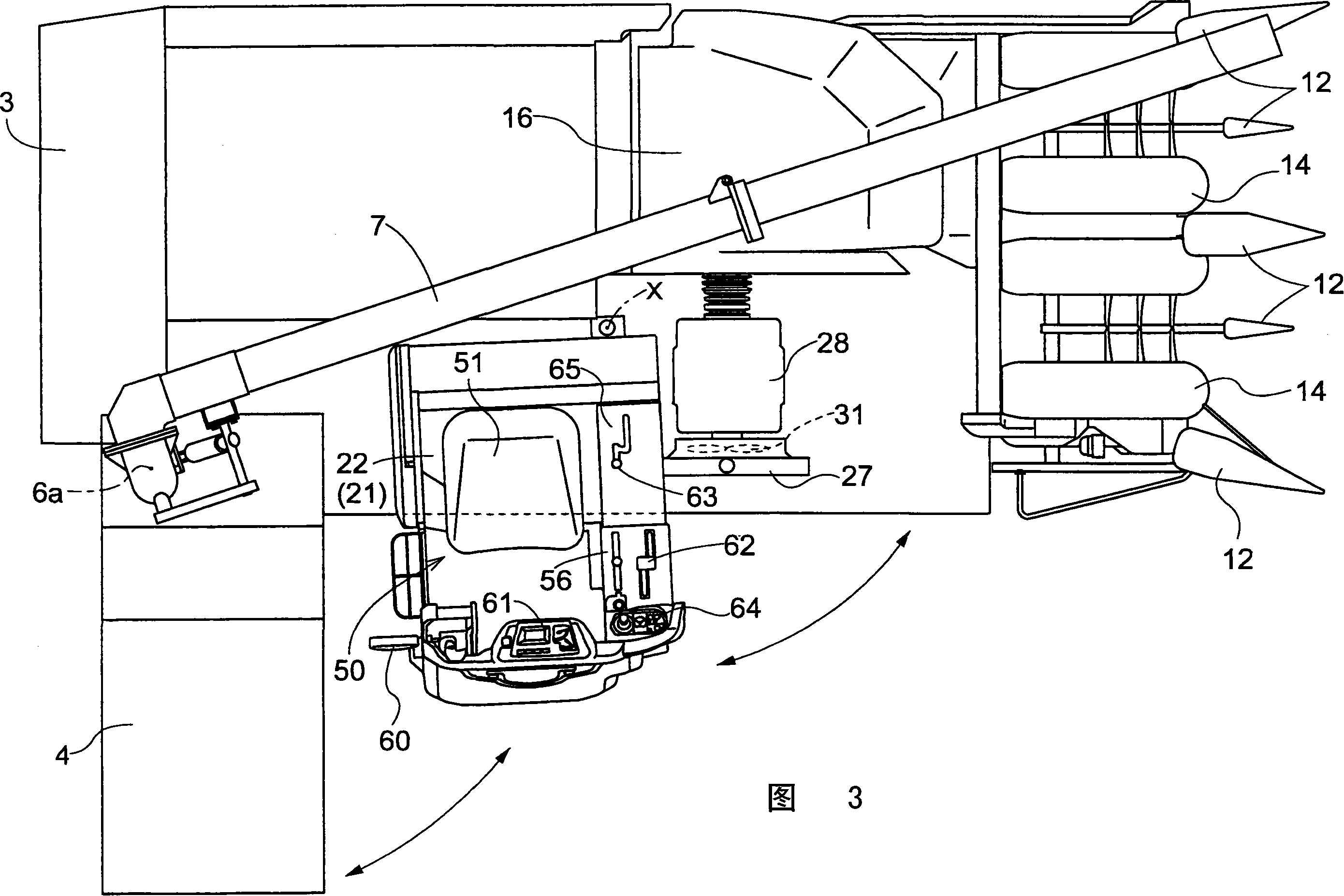

[0085] Fig. 1 is an overall side view of a combine harvester according to an embodiment of the present invention. Fig. 2 is an overall plan view of the combine according to the embodiment of the present invention. As shown in these figures, the combine harvester related to the embodiment of the present invention is provided with a body having a crawler belt traveling device 1, a harvesting section 10 connected to the front part of the body frame 2 of the body, arranged in a horizontal direction along the body, and mounted on the above-mentioned The threshing device 3 and the grain box 4 at the rear of the body frame 2.

[0086]The combine harvester is a device for harvesting grains such as rice and wheat. That is, the harvesting unit 10 is vertically arranged to be positioned at the front end of the harvesting unit 10 by a hydraulic cylinder (not shown) that swings the main frame 11 of the harvesting unit 10 up and down relative to the body frame 2 . The crop divider 12 is l...

no. 2 Embodiment approach

[0127]Next, the combine harvester which concerns on 2nd Embodiment is demonstrated, referring drawings following FIG. 23. FIG. In the following description, the same reference numerals are assigned to the same members as those of the first embodiment, and description thereof will be omitted.

[0128] As shown in Fig. 23 and Fig. 24, the threshing device 3 equipped with the threshing feed chain 3a, the driving part 50, etc. are mounted on the traveling body traveling by the crawler traveling device 1, and the combine harvester will be equipped with a pull-up device. 14. The harvesting unit 10 such as the harvesting device 15 and the supply device 16 for transporting the harvested straw is arranged in front of the traveling body, and the rear of the threshing device 1 is equipped with a straw discharge processing device 210 .

[0129] As shown in FIG. 23 and FIG. 24, the cylindrical main frame 209B used also as a transmission case is extended toward the front from the front-end|...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com