Automatic detection device of fuel charger

A technology of automatic detection device and fuel dispenser, which is applied in distribution devices, special distribution devices, liquid distribution, conveying or transfer devices, etc., can solve the problems of large measurement errors, troublesome procedures, slow speed, etc. Simple and efficient results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

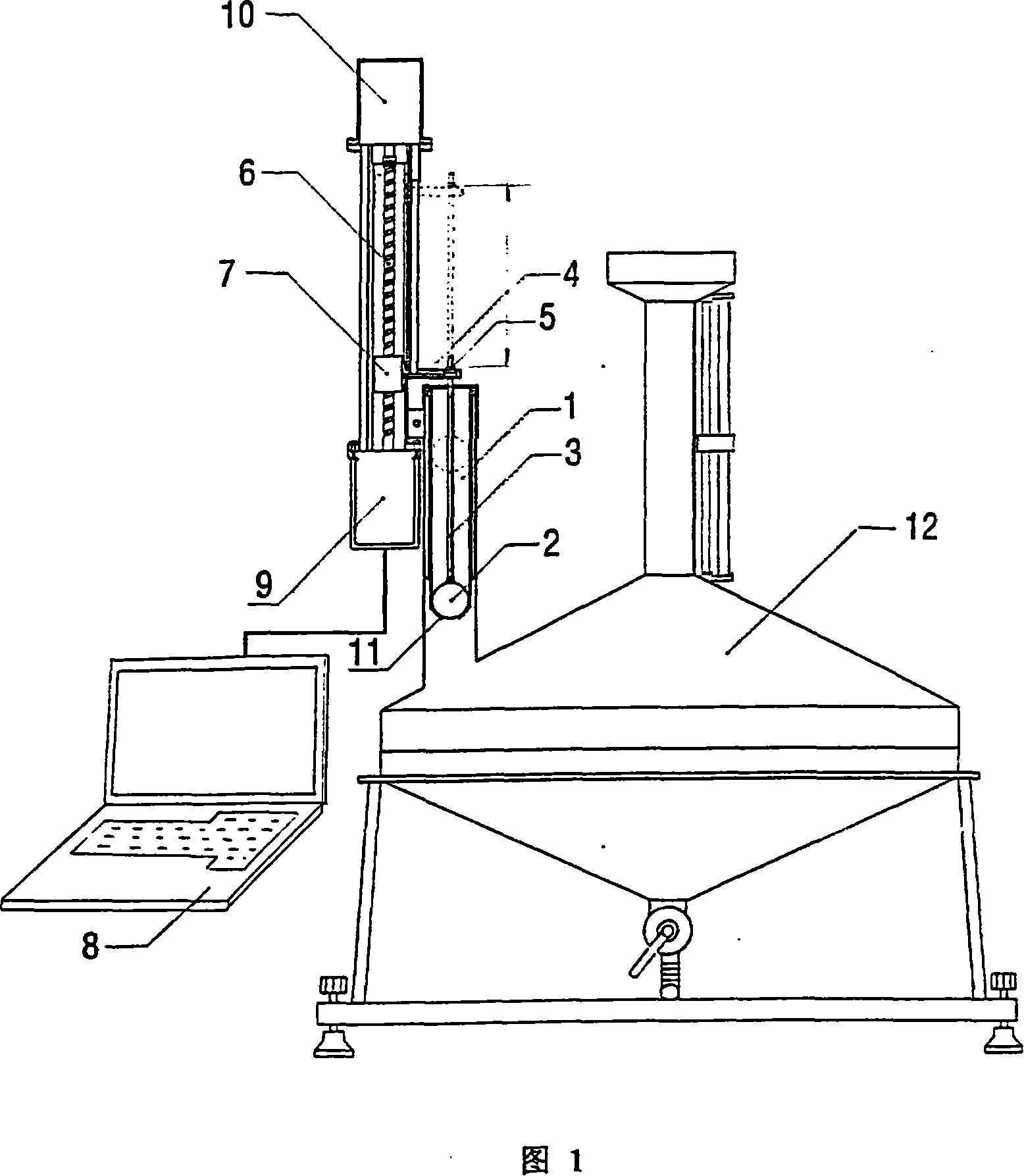

[0008] The present invention will now be further described with reference to the accompanying drawings,

[0009] An automatic detection device for a fuel dispenser, comprising a standard measuring cylinder 12, and its structure is: a hollow cylindrical straight pipe 1, with a float 2 of approximately the same diameter inside, the upper part of the floating ball is vertically topped with a straight rod 3, extending out of the straight pipe A measuring head 5 is fixed on the outer straight rod last week, and its outer jacket is a strip-shaped induction head 4. The induction head is connected with the ball nut 7 mounted on the parallel ball screw 6, and one end of the screw is connected with the portable computer 8. The micromotor 9 is connected to the shaft, and the other end of the screw rod is equipped with a coded transmitter 10 connected to the operation display;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com