Retting hemp water resolved loose washer

A loose and glued technology, applied in mechanical treatment, fiber treatment, fiber mechanical separation, etc., can solve the problems of low work efficiency, high resistance to hemp moving, slow washing speed, etc. The effect of forward resistance and improving the speed of hemp washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

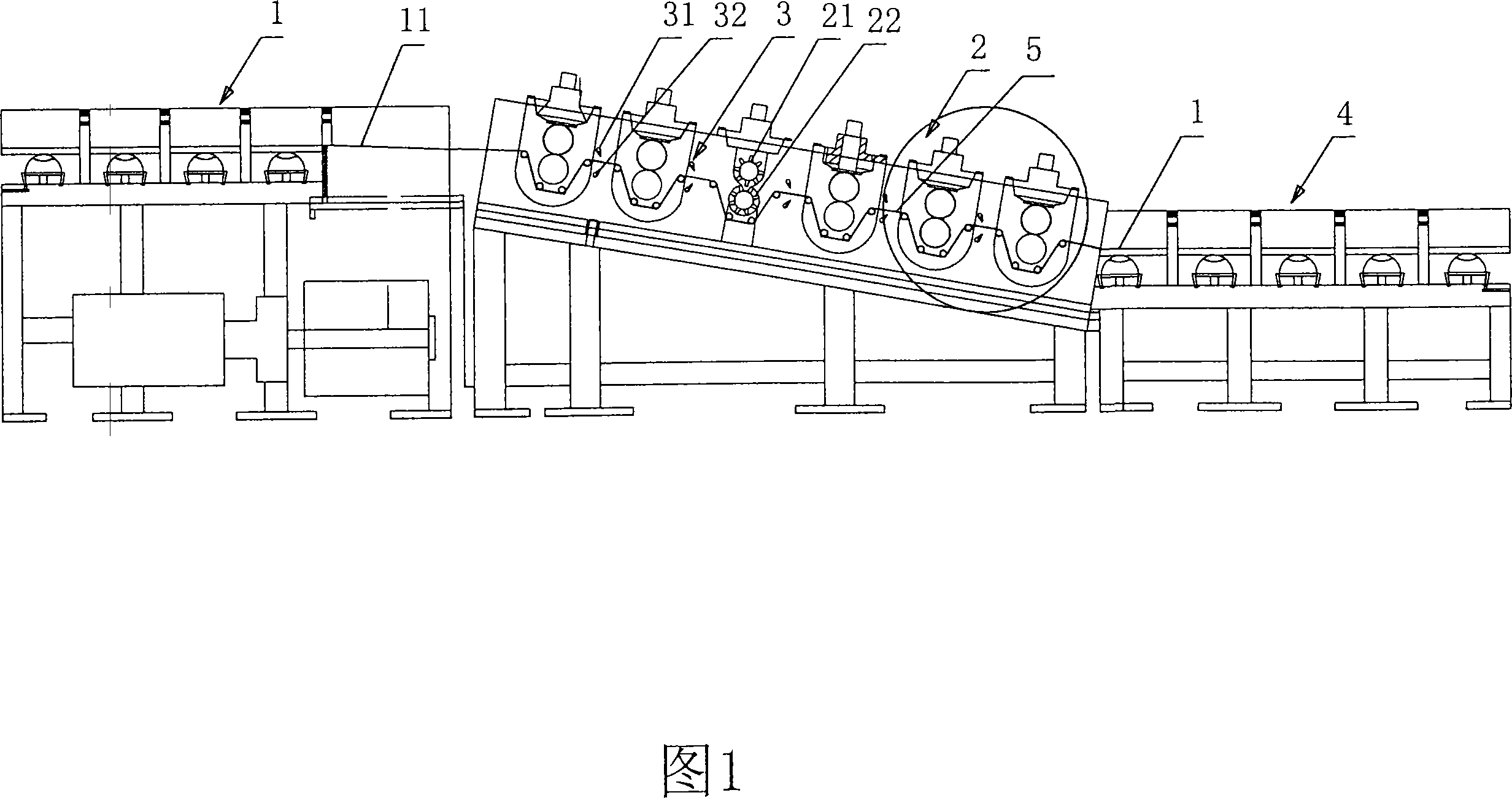

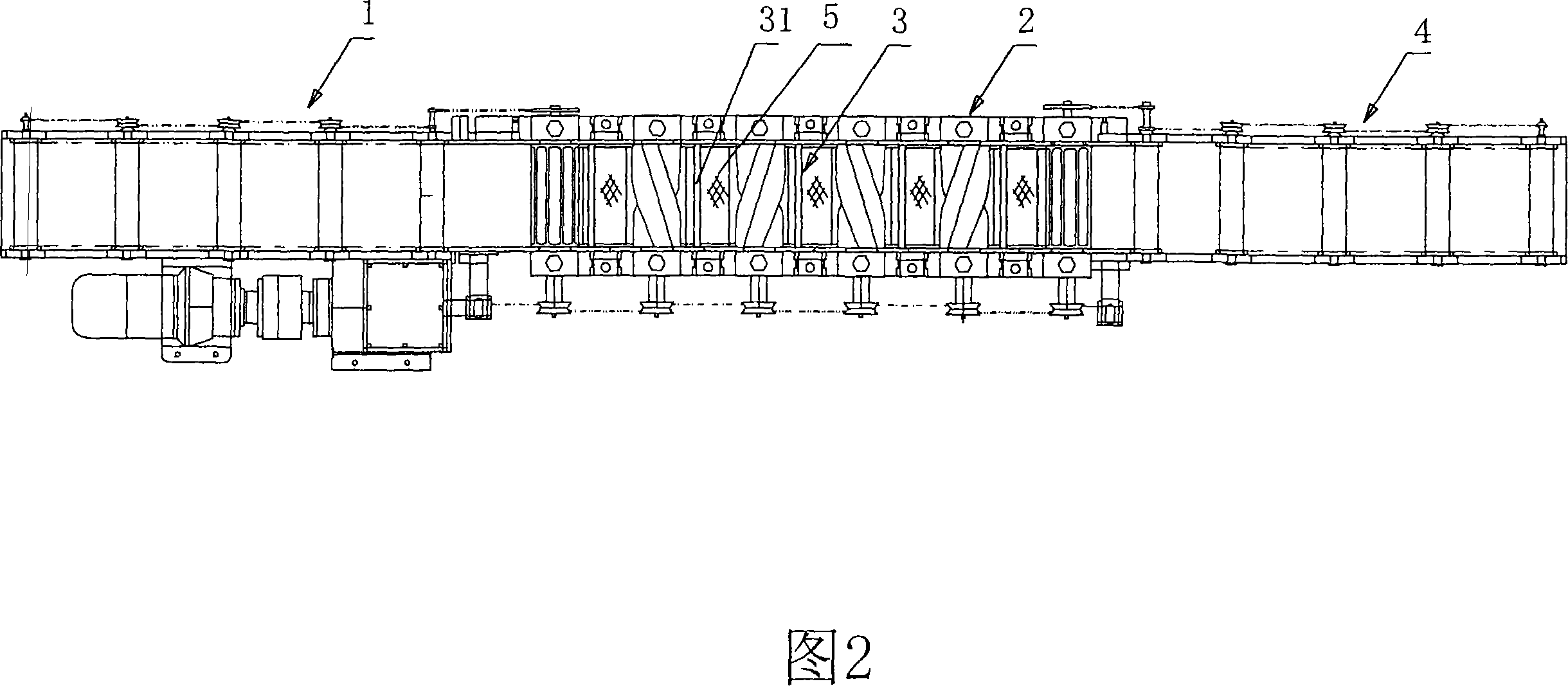

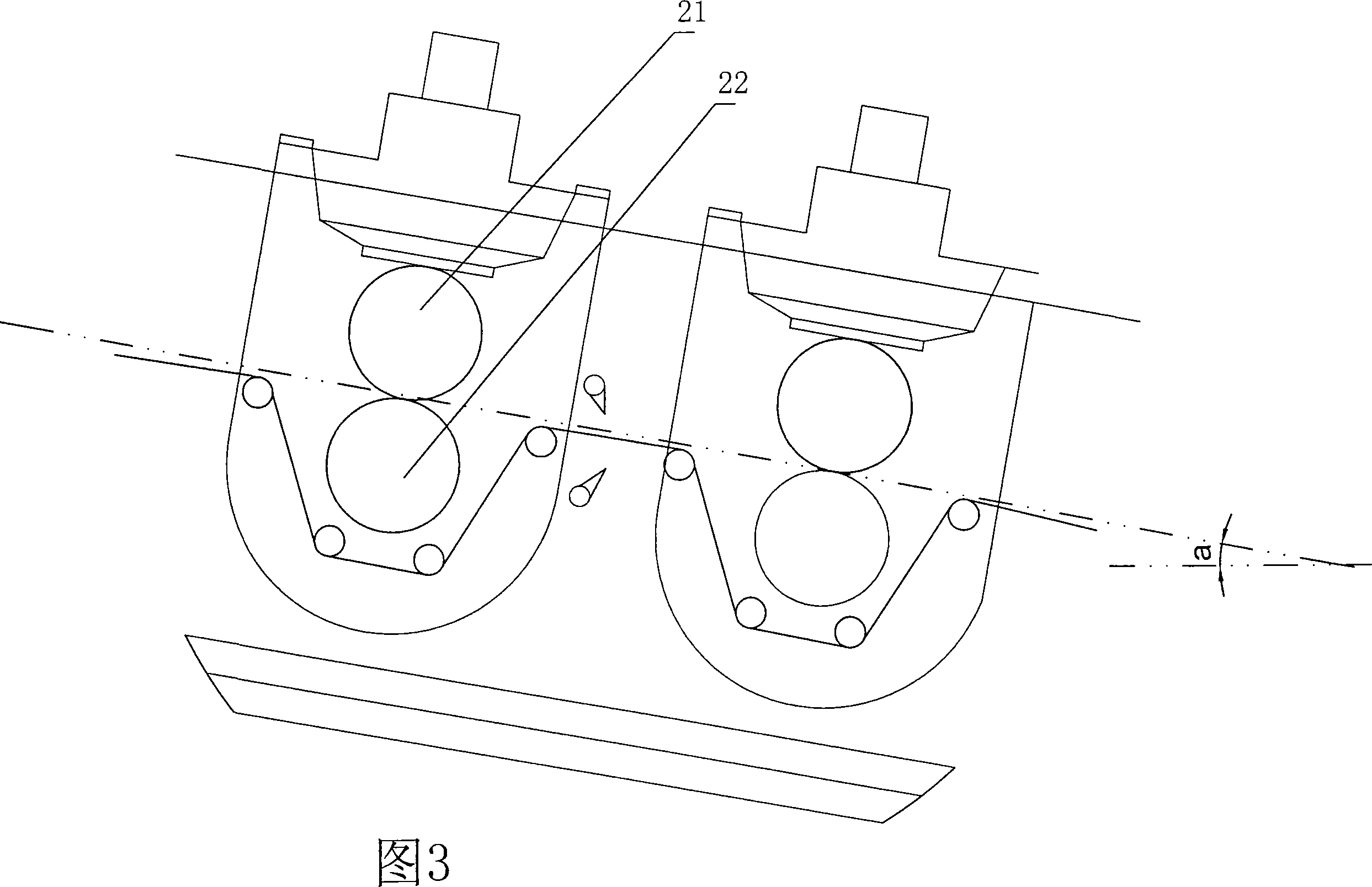

[0014] It can be seen from Fig. 1-Fig. 3 that the present invention comprises a hemp feeding mechanism 1, a rolling mechanism 2, a spraying mechanism 3 and a hemp discharging mechanism 4, and the hemp feeding mechanism 1 and the hemp discharging mechanism 4 are located at the beginning and end of the rolling mechanism 1 respectively. two ends, and the hemp feeding mechanism 1 is higher than the hemp discharging mechanism 4. The hemp feeding mechanism 1 and the hemp output mechanism 4 still have the conveyor belt (11,41) driven by the motor, and the rolling mechanism 2 has many pairs of master-slave roller pairs (21,22) that are engaged with each other. Gradually lower from one end of the hemp feeding mechanism to the one end of the hemp discharging mechanism, and the inclination a is greater than 0 degrees and not greater than 90 degrees, wherein the driving roller is driven by the motor through the transmission part, and the driving roller and the driven roller are meshed with...

Embodiment approach 2

[0016] Fig. 4-Fig. 5 has reflected the structure of embodiment two, can find out from the figure that this embodiment is compared with embodiment one, and embodiment two has replaced traction mesh belt 5 with deflector plate 6, and each deflector plate and each There is a gap between the rollers, and the upper shower pipe 31 and the lower shower pipe 32 are located at the gap and flush the hemp up and down. The inclination angle a of each pair of rollers arranged from high to low is between 15-90 degrees, preferably between 45-90 degrees, and the hemp is guided from the upper pair of rollers to the lower pair of rollers through the deflector. This embodiment partially utilizes the dead weight of hemp, and is simpler in structure than embodiment one.

Embodiment approach 3

[0018] Figure 6-Figure 7 reflects the structure of the third embodiment, it can be seen from the figure that this embodiment has neither traction mesh belt nor deflector, but requires the angle between the injection direction of the upper and lower spray pipes and the hemp channel β is greater than 0 degrees and not less than 90 degrees, preferably between 15-40 degrees, and requires that the inclination angle a of each roller pair arranged from high to low is between 70-90, preferably between 75-85 degrees, so that the Utilize self-weight to sag, and then directly clamp the anesthesia by the upper and lower spray pipes (31, 32). The structure of this embodiment is the simplest, and at the same time, the hemp can be degummed and loosened more fully.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com