Steel truss of through bridge

A steel truss and truss technology, applied in truss bridges, bridges, bridge forms, etc., can solve problems such as excessive material consumption, difficulty in production, construction and post-maintenance, and achieve low cost, easy processing and installation, and reduced lateral amplitude. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

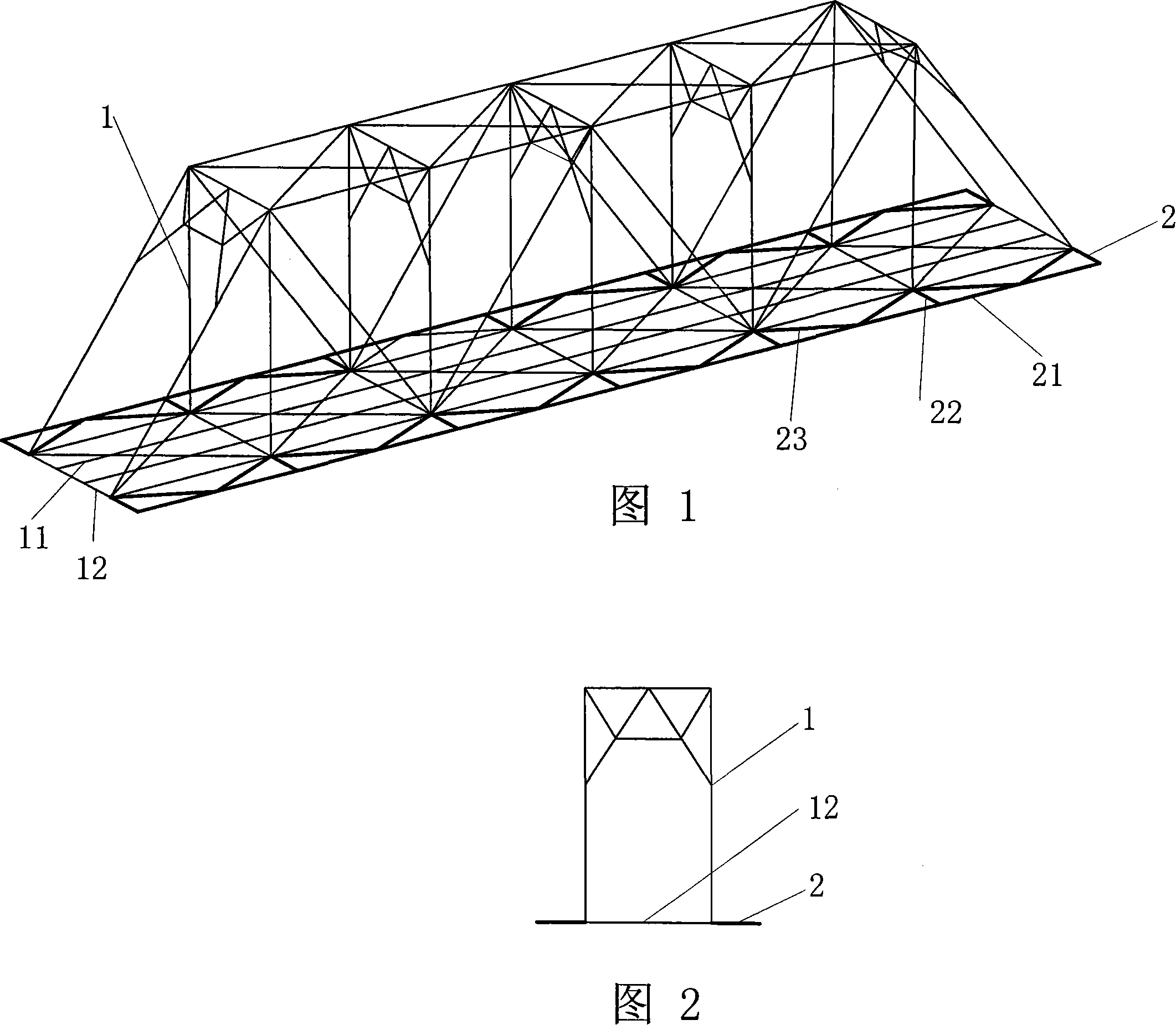

[0014] Figures 1 and 2 show that a specific embodiment of the present invention is: a steel truss of an underpass bridge, including a truss 1 with a rectangular cross section. Both sides of the bottom of the truss 1 are fixedly connected with a plane bracket 2 of steel structure, and the plane bracket 2 is on the same plane as the bottom of the truss 1 .

[0015] The planar bracket 2 is composed of: the end of the bottom beam 12 of the truss 1 is extended to connect the cross brace 22, the chord 21 connected with the cross brace 22 and parallel to the longitudinal beam 11, and several chords 21 and the cross brace 22 constitute There are oblique braces 23 connected obliquely in the rectangular internodes, and the chords 21 , cross braces 22 and diagonal braces 23 form the plane bracket 2 .

[0016] Obviously, in practical implementation, the beam 12 and the cross brace 22 of the present invention can be an integrated structure composed of a steel piece.

[0017] There are one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com