Corrugated pipe fatigue life test machine cramping apparatus

A fatigue life and corrugated pipe technology, applied in the field of fixtures used in testing machines, can solve the problems of scrapped corrugated pipes, affected material properties of corrugated pipes, incorrect test data, etc., and achieve the effect of convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

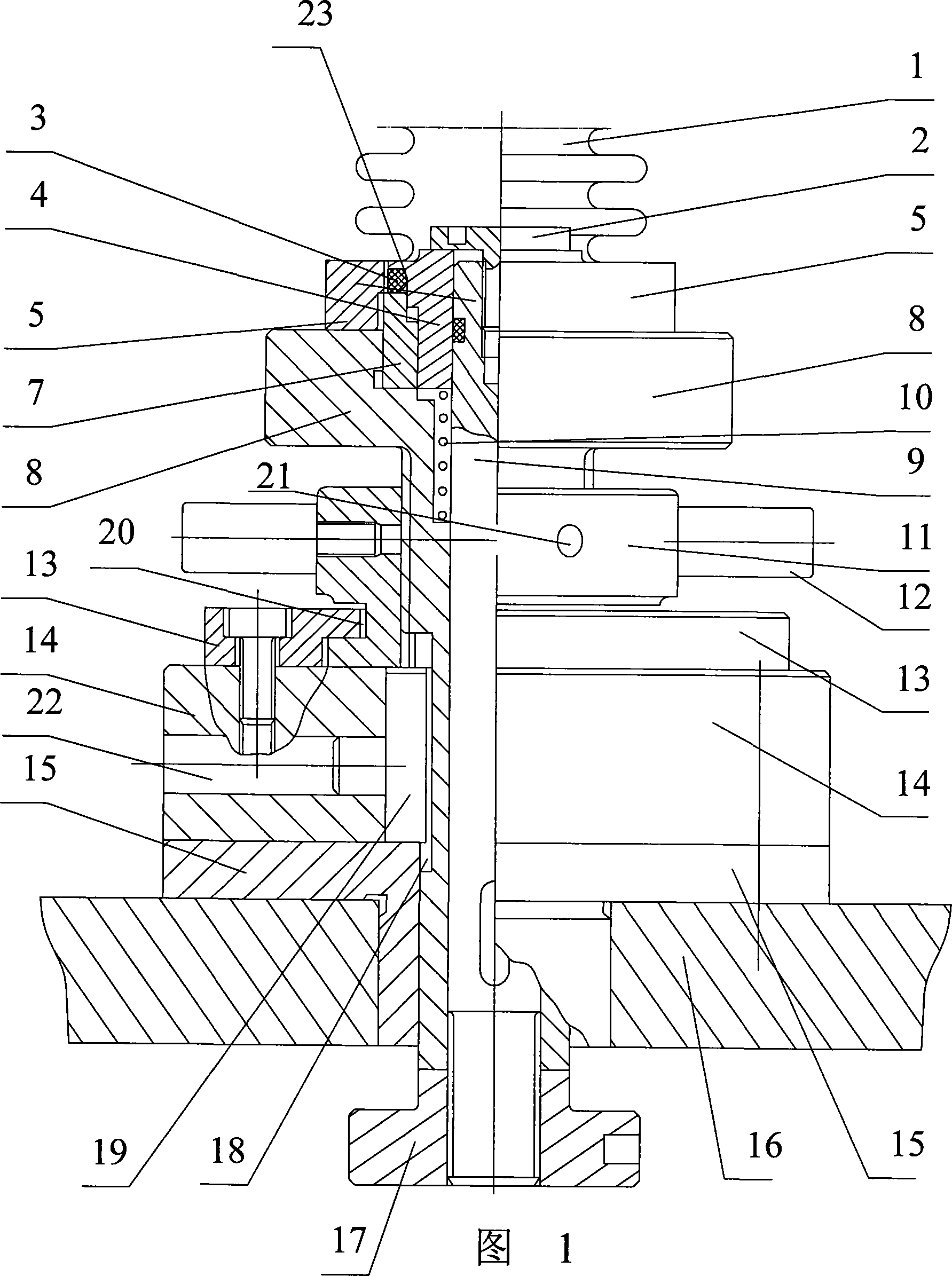

[0014] In the figure: 1 is the corrugated pipe to be tested, 2 is the gland, which is tightly connected with the tie rod 9; 3 is the sealing ring, which is used to fix and seal the bellows 1; 4 is the tension sleeve, which is used to compress the sealing ring 3; 5 7 is the middle seat; 8 is the fixture seat; 9 is the pull rod. When the pull rod 9 is pulled down, the gland 2 presses the tension sleeve 4 so that the sealing ring 3 is supported. Tighten the inner diameter of the bellows 1; 10, the spring, used to reset the pull rod; 11, the adjustment disc, used to adjust the upper and lower positions of the clamp seat and the pull rod, so as to adapt to bellows of different specifications; 12, the adjustment rod, used to drive the adjustment disc; 13. The limit plate is used to guide and limit the pull rod; 14. The support plate is used to support components such as the adjustment plate and the fixture seat; 15. The base acts as a support member; 16. The pull rod head is located ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com