Leaded light image amplification screen

An optical image and screen technology, applied in the video field, can solve the problems of increasing optical fiber optical loss, high manufacturing cost, rising splicing cost, etc., and achieves the effect of good viewing effect, good integrity, and elimination of physical seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

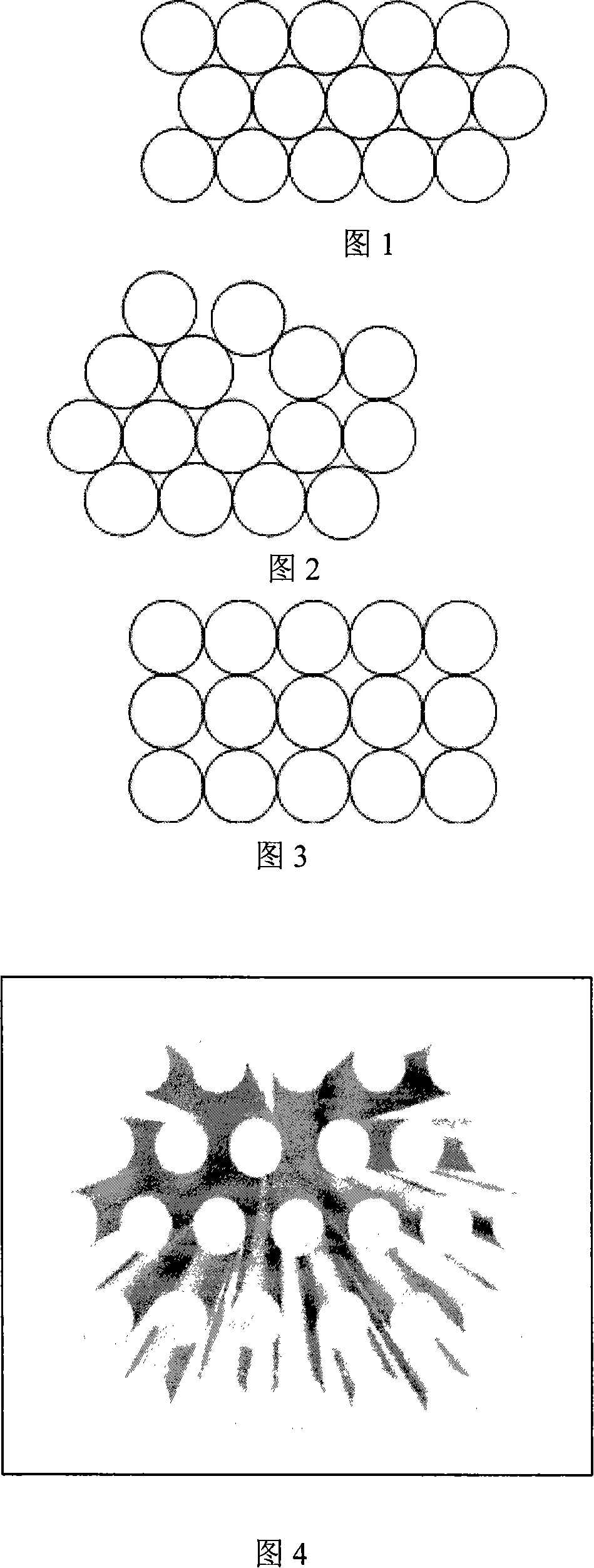

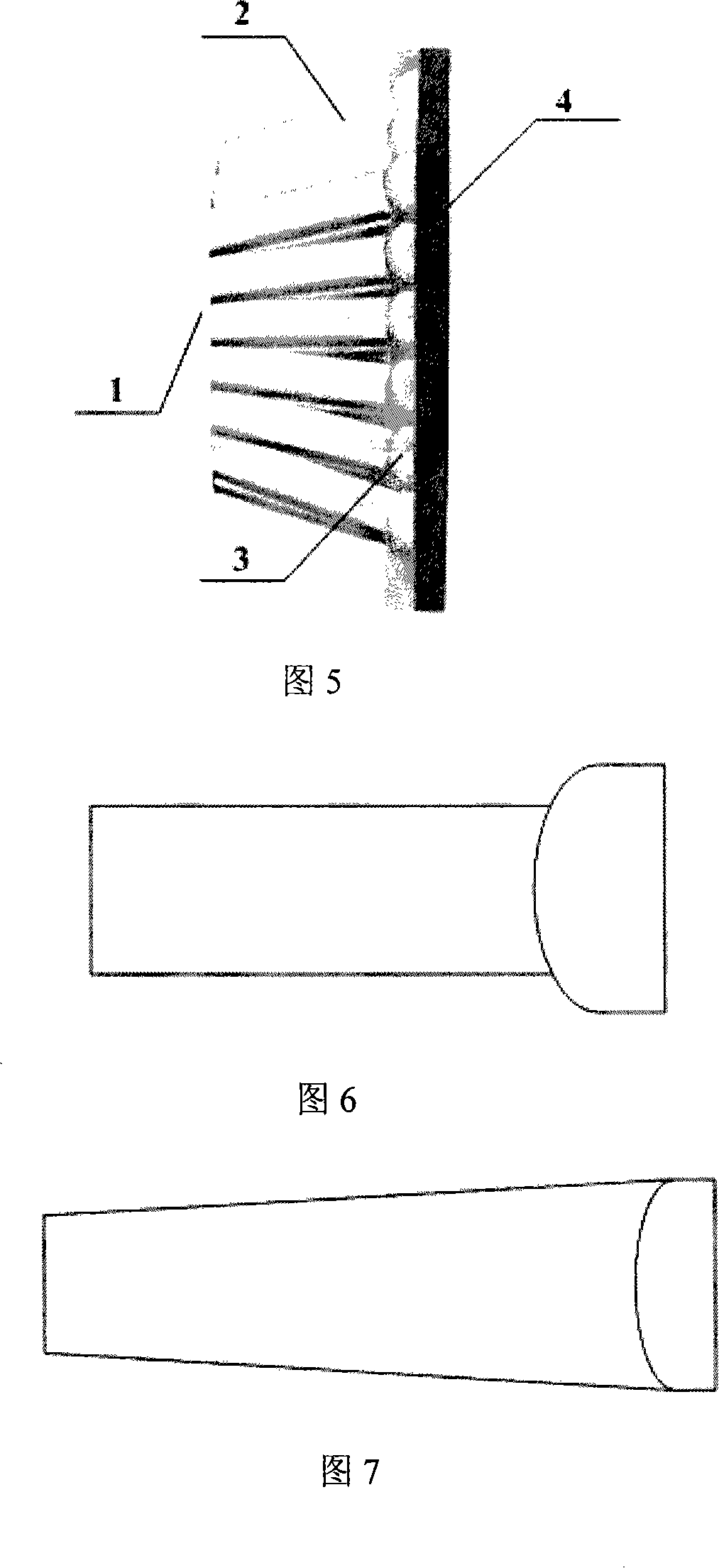

[0023] Embodiment 1: According to Figure 7, produce a mirror-changing optical fiber with a thin end and a thick end. The length of the optical fiber is 30-200mm. After grinding, polishing, and pasting the front light-transmitting layer, the light-receiving surface is formed. A light guide screen is formed by bonding the front light-transmitting layer and the rear-end light-transmitting layer.

Embodiment 2

[0024] Embodiment 2: According to Fig. 6, the uniform-diameter optical fiber with micromirror is produced, the length of the optical fiber is 30-200 mm, the light-receiving surface is piled up in a dense stacking manner and tightened and bonded according to the geometric size of the light-receiving surface light source, and the light-receiving surface is cut and polished , polishing, and pasting the front-end light-transmitting layer to form a light-receiving surface. A light guide screen is formed by bonding the front light-transmitting layer and the rear-end light-transmitting layer.

Embodiment 3

[0025] Embodiment 3: stick the optical fiber on the back-end light-transmitting layer with a micromirror, clamp and stick the optical fiber on the light-receiving surface according to the geometric size irradiated by the light source on the light-receiving surface, cut, polish, polish, and paste the front end of the light-receiving surface A different light image magnification screen is formed behind the light-transmitting layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com