Fixer for heat radiator

A technology for fixing devices and heat sinks, which is applied in the direction of instruments, instrument cooling, electric solid devices, etc., can solve the problems of increasing the cost of heat sinks, and achieve the effect of easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

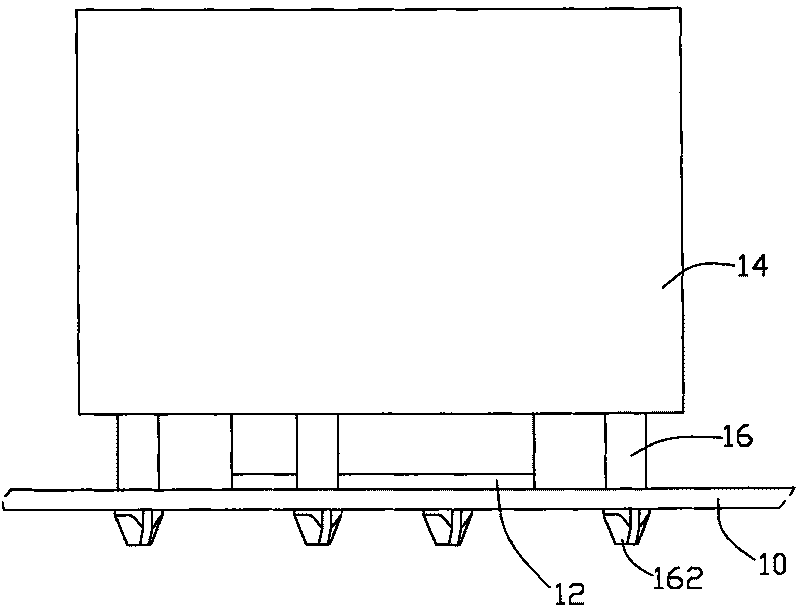

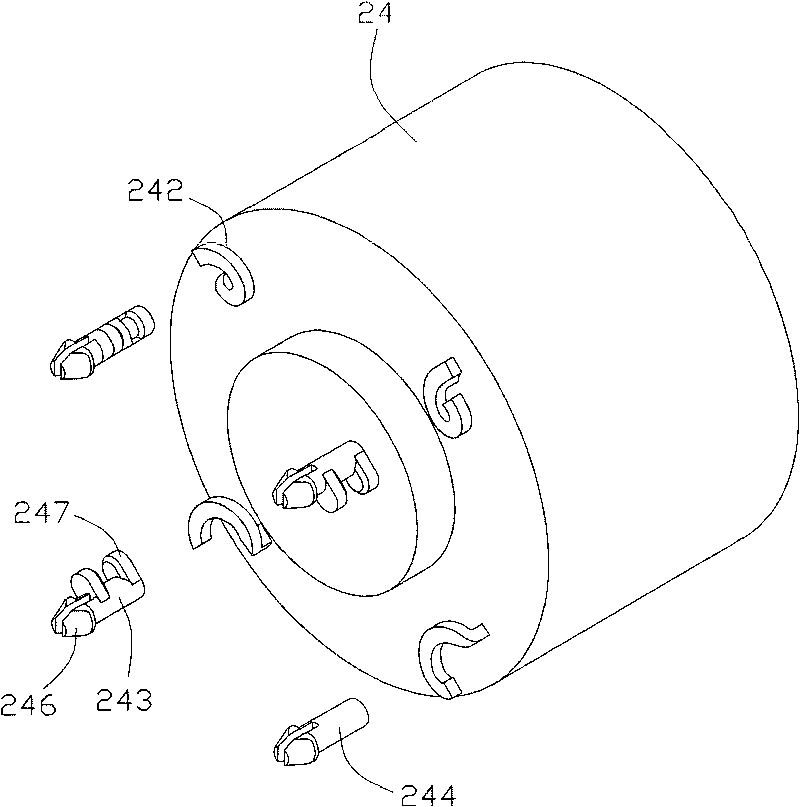

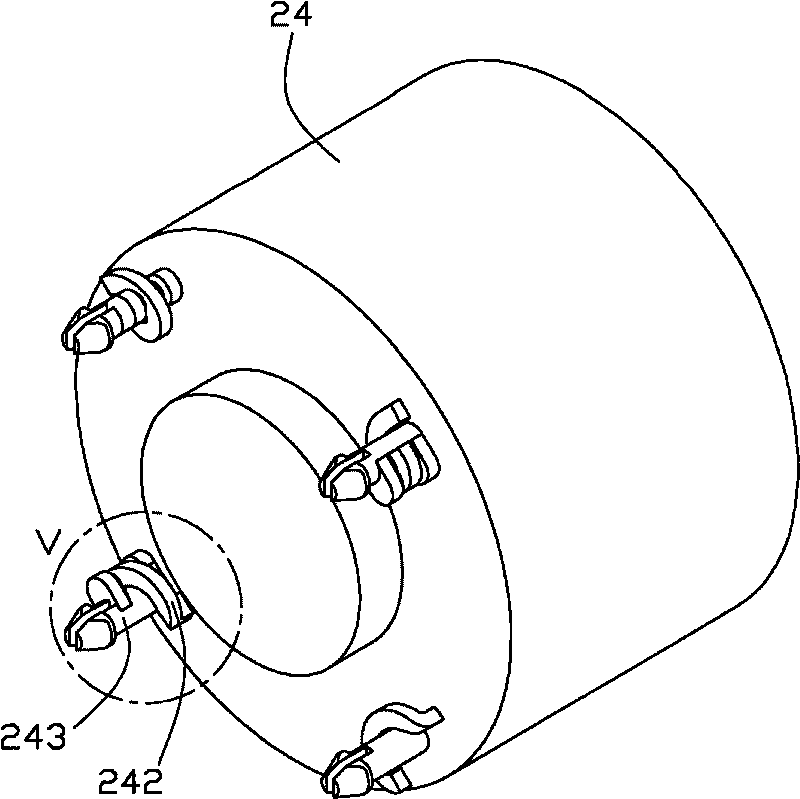

[0013] Please refer to Image 6 , is a preferred embodiment of the radiator fixing device of the present invention, and is used to fix a radiator 24 on a heating element 22 of a computer motherboard 20 . The radiator fixing device includes four fasteners 242 arranged on the bottom of the radiator 24 in an orthogonal direction and four buckles 243 fixed on the computer motherboard 20, the fasteners 242 and the clips The fasteners 243 are snap-fitted by mutual friction, and the heat sink 24 is fixed on the heating element 22 .

[0014] Please refer to Figure 2 to Figure 4 , each fixing piece 242 is in a spiral shape, one end is fixed on the bottom of the radiator 24, and the other end is a free end. Each buckle 243 includes a cylinder 244, and the lower end of the cylinder 244 is an elastic buckle 246. The buckle 246 is in the shape of an inverted cone, and its upper diameter is larger than that of the cylinder 244. The diameter of its lower part is smaller than the diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com