Vulcanizing tank device with novel suspending structure

A hanging device and vulcanization tank technology, applied in the field of vulcanization tank devices, can solve problems such as unfavorable promotion and application of tire retreading technology, consumption of operator's physical strength and time, long time interval for opening and closing the tank body, etc., so as to shorten the vacancy time and shorten the The effect of opening time and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

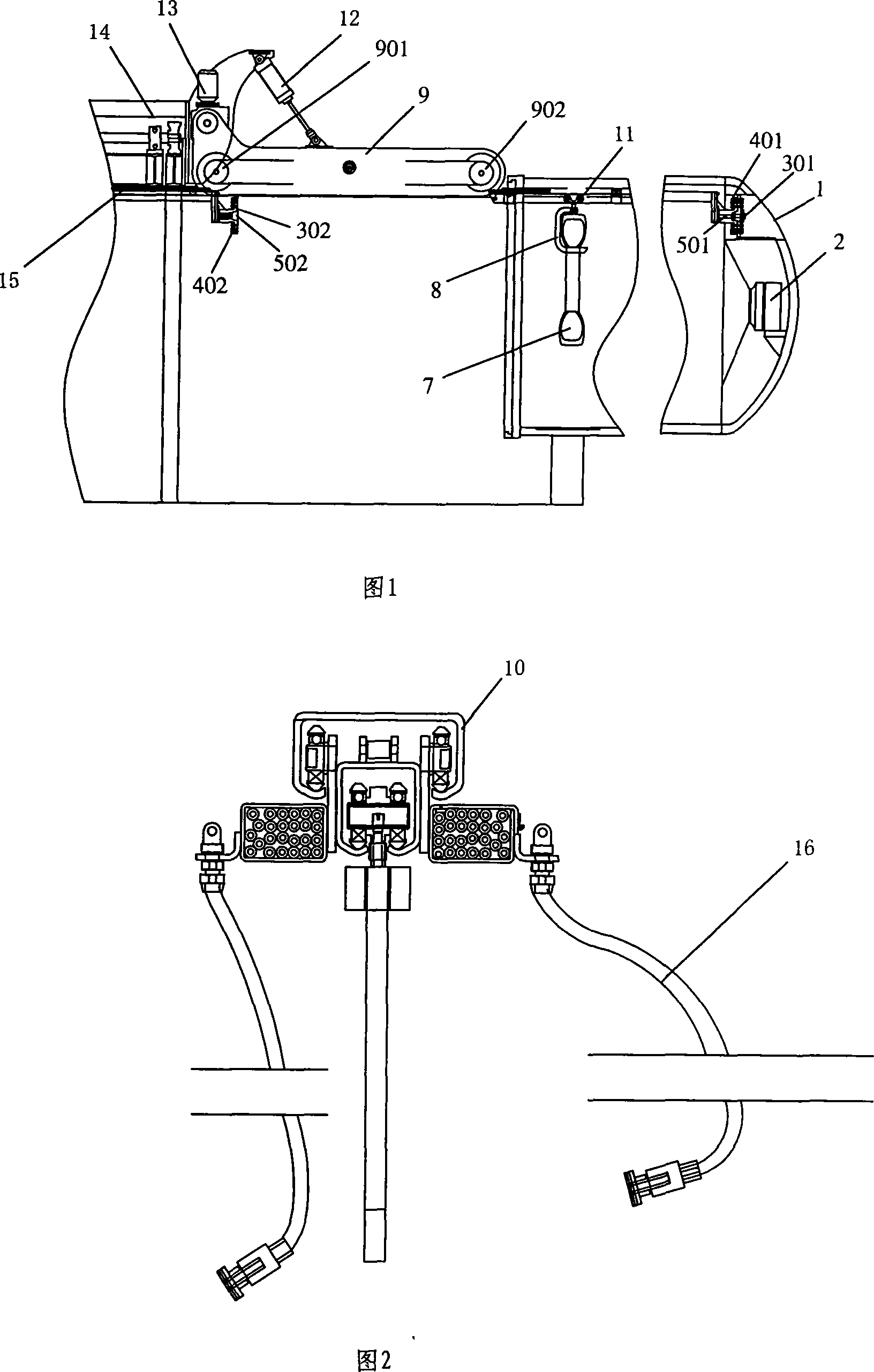

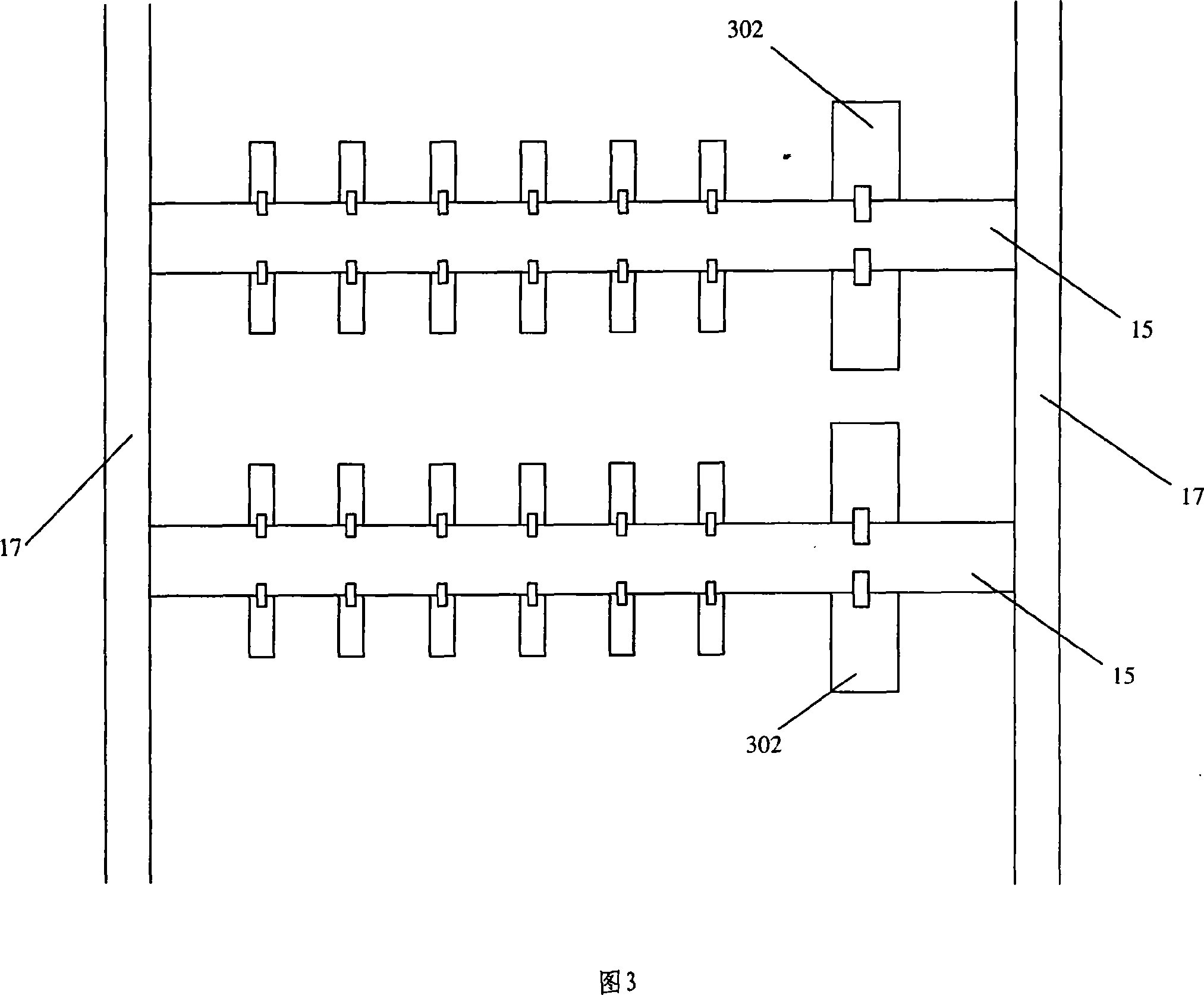

[0024] Fig. 1 is a schematic diagram of the structure of the present invention, and Fig. 2 is a schematic diagram of the structure of the pipeline connection system in the tank of the present invention. The tank body 1 is fixed with a tank inner rail 10, and the end of the rail 10 is provided with a fixed pipe connection plate 301. Several quick connectors 401 for pressure vessels are distributed on the surface of the pipe connection plate 301. The central position of the pipe connection plate 301 is provided with a positioning Pin-type guide shaft 501 . The pipeline connection plate 301 is fixed on the inner wall of the tank body 1 through the pedestal 2, each quick joint 401 is connected with the inflation and deflation device outside the tank through the pipeline 16, and the tire inflation and deflation and vacuum extraction in the tank are controlled by the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com