LED road lamp

A technology for LED street lamps and substrates, which is applied in the loss prevention measures of lighting devices, cooling/heating devices of lighting devices, outdoor lighting, etc., can solve the problem of inability to adapt to the long-term working requirements of street lamps, inability to form effective convection, and low air heat transfer coefficient and other problems, to achieve the effect of good heat dissipation, help heat dissipation, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

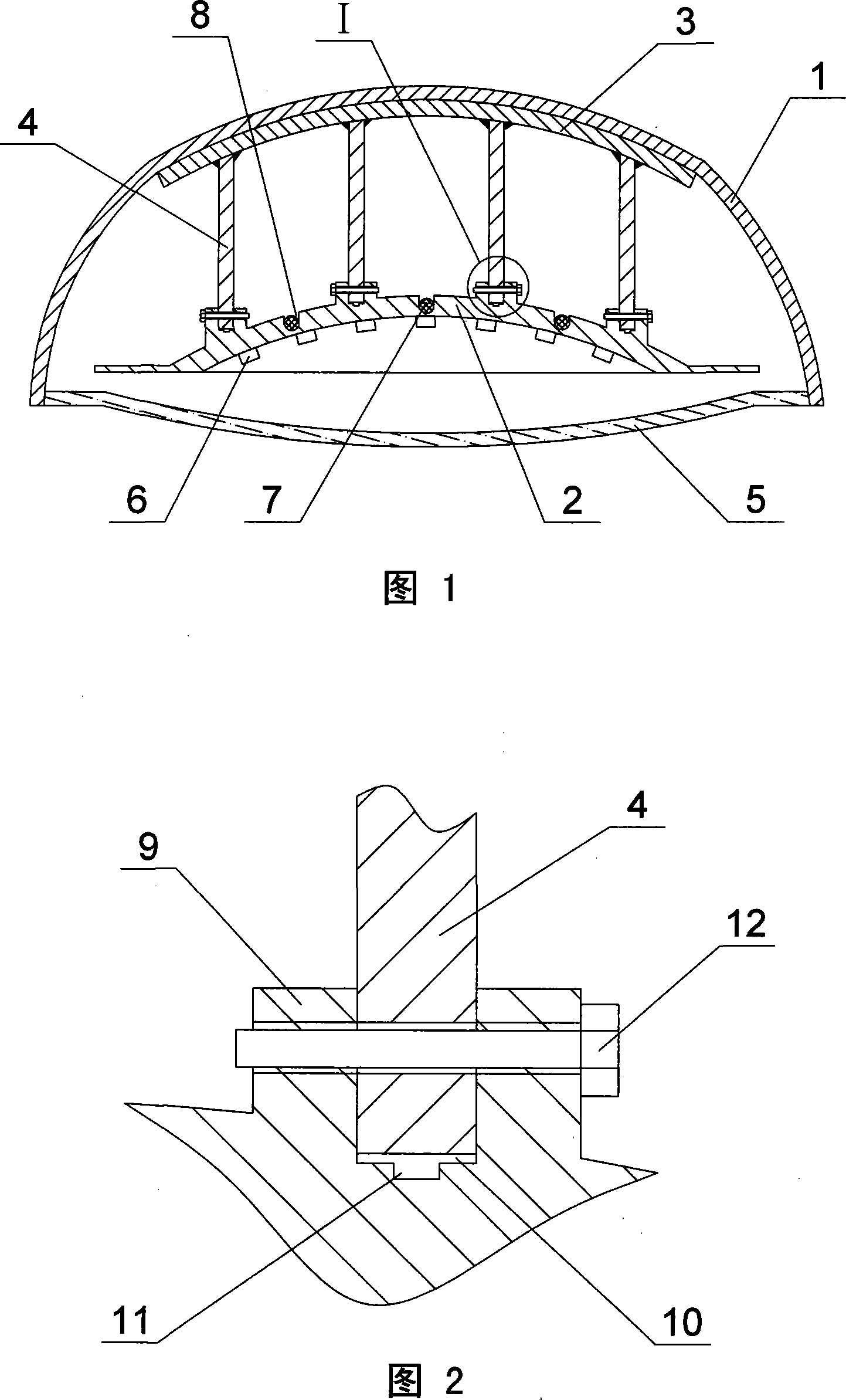

[0027] As shown in Figures 1 and 2, the present invention includes a metal back cover 1, a substrate 2, a heat-conducting back plate 3, several heat-conducting ribs 4, a light-transmitting front cover 5, and several LEDs 6, and several LEDs 6 are mounted on the The front side of the substrate 2 is arranged together with the substrate 2 in the cavity surrounded by the rear cover 1 and the front cover 6. The substrate 2 is inwardly concave, and of course it can also be in other shapes such as outwardly convex , the back side of the substrate 2 is provided with several wire grooves 8 and several convex parts 9, of course, the wire grooves 8 can also be arranged on the front of the substrate 2, and the wires 7 are placed in the wire grooves 8, so that the wires The arrangement is neat and beautiful and easy to identify. The heat-conducting backplane 3 is in close contact with the inner surface of the rear cover 1 and the shapes of the two are compatible. The upper and lower parts o...

Embodiment 2

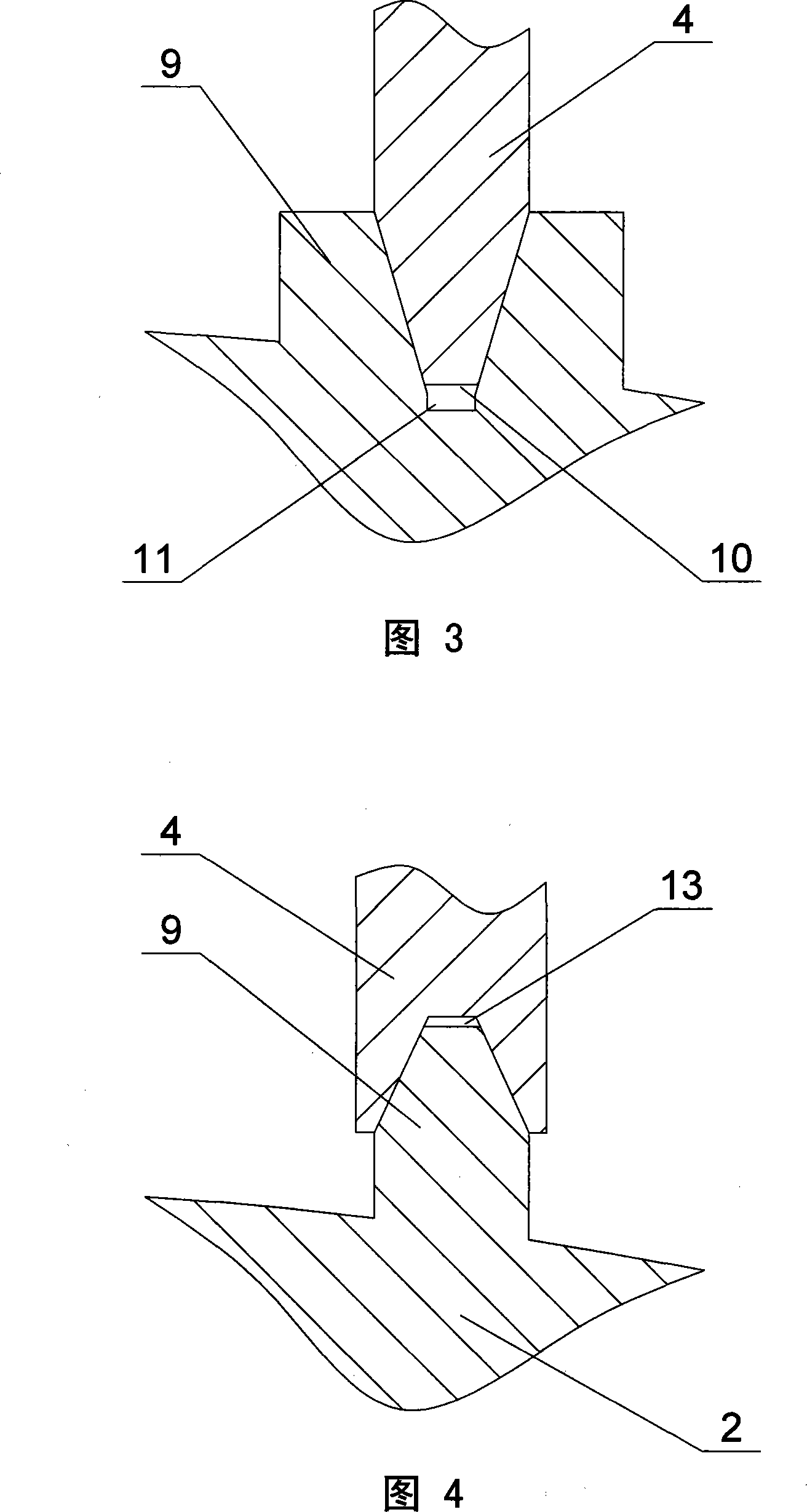

[0029] As shown in Figure 3, the difference between this embodiment and Embodiment 1 is that the groove 10 is a dovetail groove, and the positioning fastener 12 is not provided in this embodiment, but is fixed by the specific shape of the dovetail groove itself. purpose of positioning.

[0030] The remaining features of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0032] As shown in Figure 4, the difference between this embodiment and the second embodiment is that: the bottom of the heat conducting rib 4 is provided with an upward groove 13, and the shape of the top of the convex part 9 is adapted to the groove 13 and fixedly arranged In the groove 13, the groove 13 is a dovetail groove, of course, the groove 13 can also be a straight groove, and the thermal conductive glue groove 11 is not provided in this embodiment.

[0033] The other features of this embodiment are the same as those of Embodiment 2.

[0034] The invention has simple structure, convenient installation, high luminous efficiency, good heat dissipation effect and long service life, and is an ideal replacement product for existing street lamps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com