Track system and concrete slab of a fixed track

A technology for concrete slabs and fixed tracks, applied in the field of track systems, can solve the problems that railway transportation cannot be interrupted, reconstruction measures cannot be taken, difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

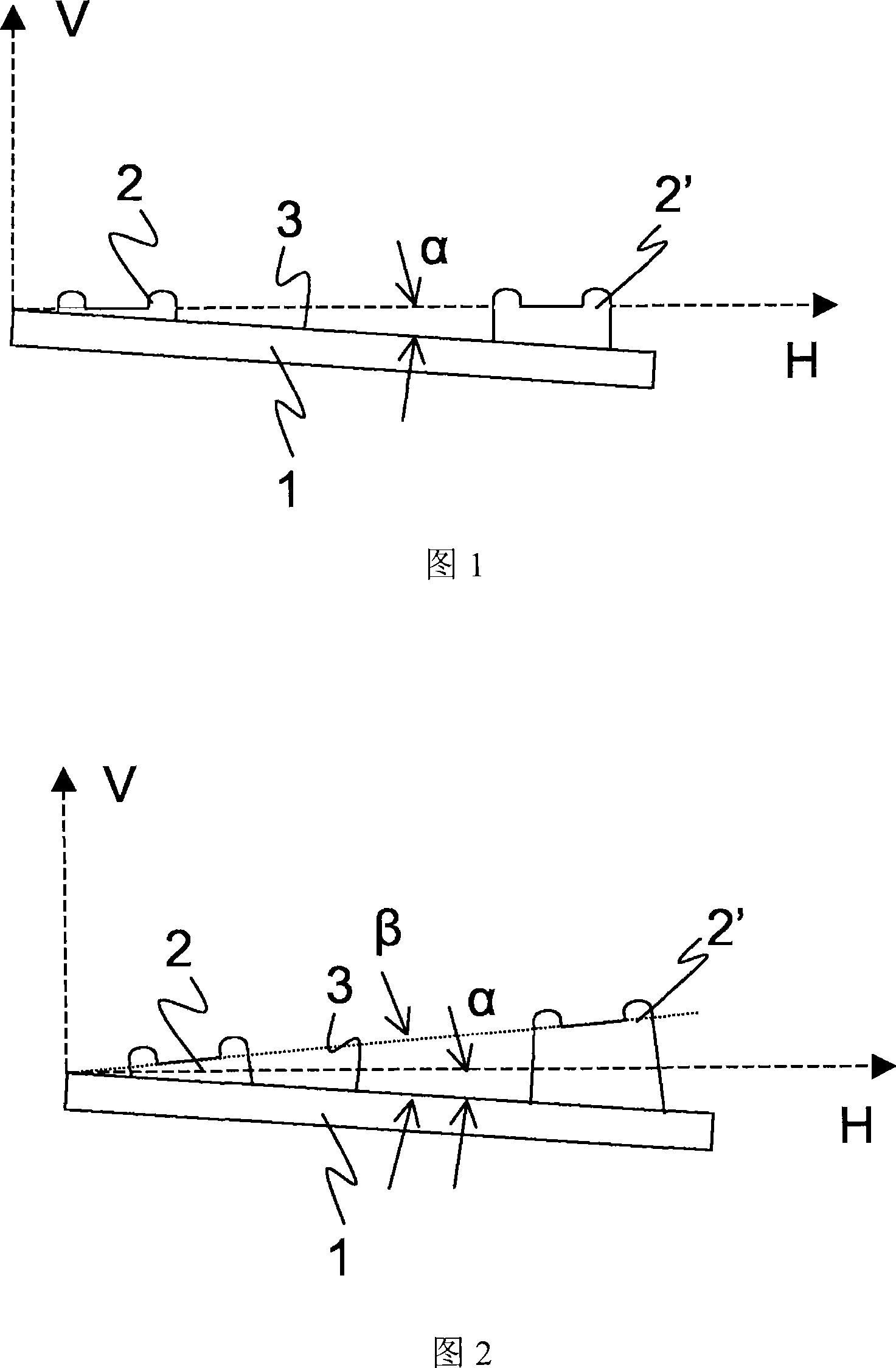

[0026] Figure 1 is a diagram of a horizontal rail arrangement, where the dotted arrow lines H and V indicate the horizontal and vertical directions, rail seats 2 and 2' have been placed on the concrete slab 1, the rail seats 2 and 2' along the horizontal line H so that the rails which are subsequently assembled on the rail bases 2 and 2' are also arranged horizontally to each other. The concrete slab 1 has an upper surface 3 inclined with respect to the horizontal H at an angle α showing the inclination of the concrete slab 1 which allows rainwater to flow out of the concrete slab 1 towards the rail seat 2'. Although the slope of the two rail supports 2 and 2' arranged parallel to one another is horizontal, the upper surface 3 of the concrete slab 1 still allows rainwater to flow out to a defined outer side. Accordingly, the rail seat 2' is made higher than the rail seat 2 in relation to the upper surface 3.

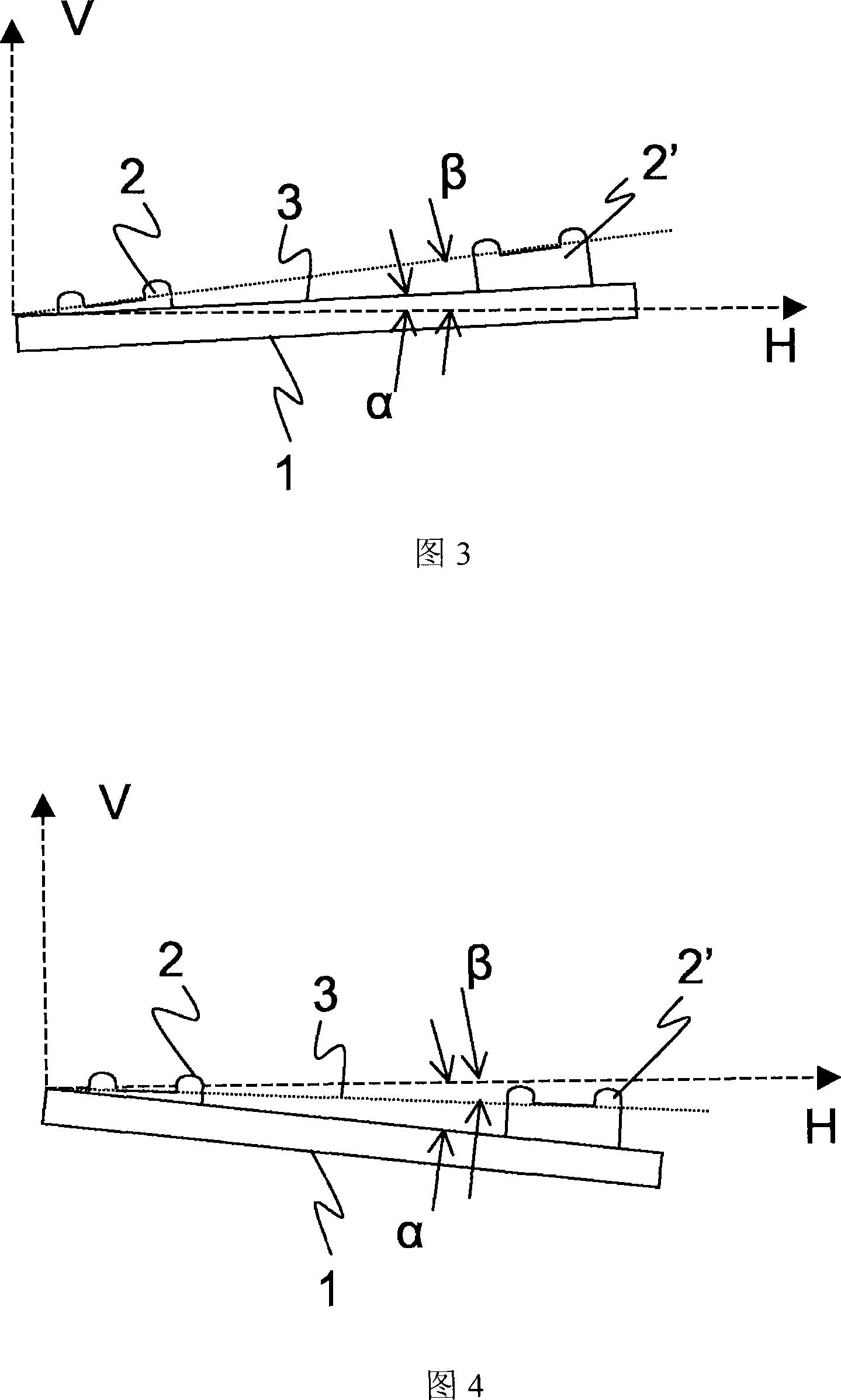

[0027] Figure 2 shows a representation of a concrete slab accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com