Differential filter automatic flushing sewage purifying device

An automatic flushing and sewage purification technology, which is applied in the direction of filtration and separation, fixed filter elements, chemical instruments and methods, etc., can solve the problems that affect the service life of the filter screen, cannot achieve high precision, and the filter screen loses water permeability, etc., to achieve High filtration accuracy and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and concrete example for further description:

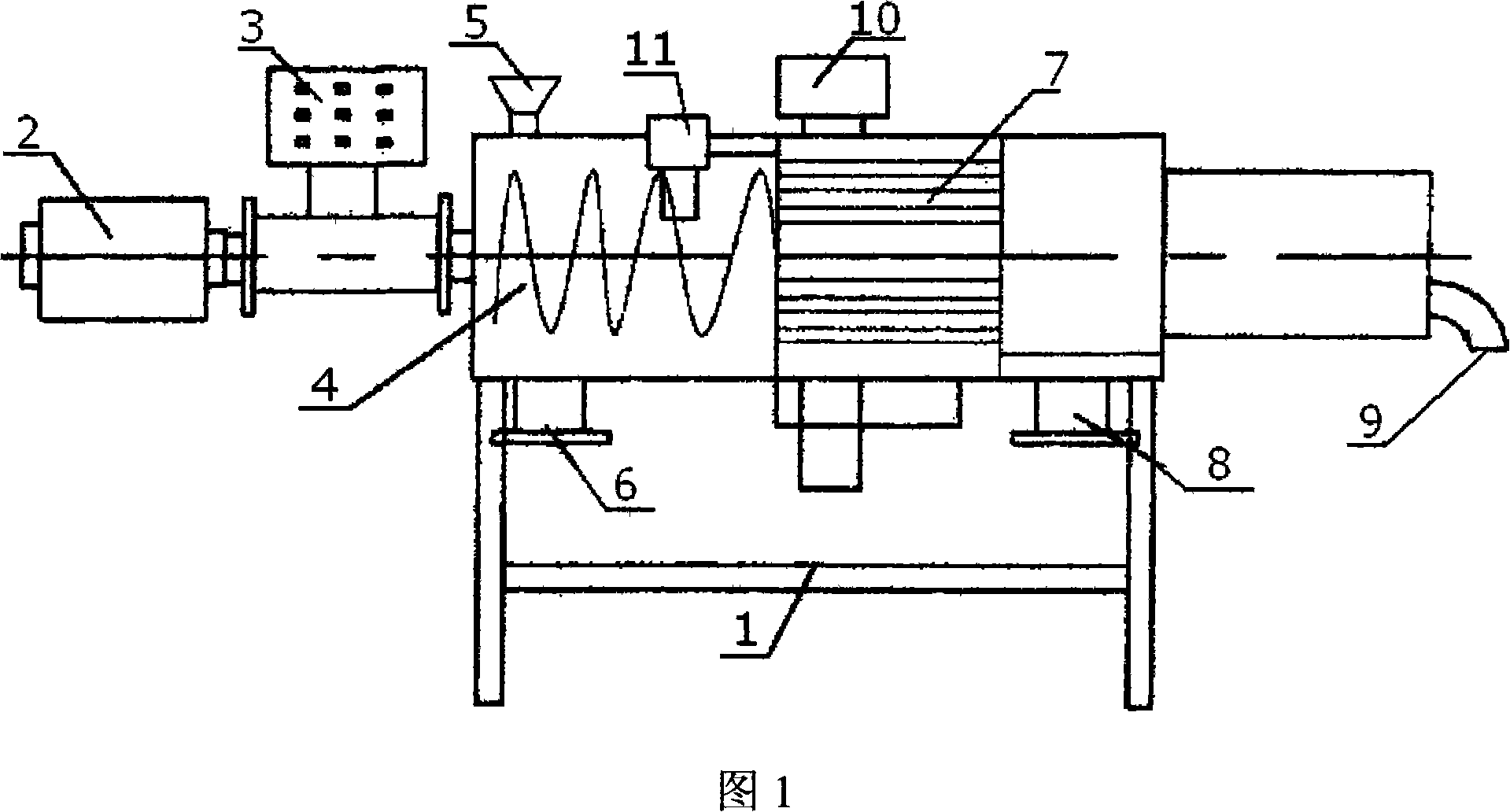

[0016] As shown in the figure, the pressure difference filtration automatic flushing sewage purification device of the present invention includes a base 1, a raw water pump, a body installed on the base 1, a driving mechanism 2 and an electric control mechanism 3, wherein the body is composed of a stirring mixing area and a filtering area. The stirring and mixing zone includes a stirring device 4 driven by a driving mechanism 2, an additive filling port 5 and a raw water inlet 6, and the filtering zone includes a filtering mechanism 7, a slagging mechanism connected to a sewage outlet 8, a clean water outlet 9, and a backwashing mechanism 10; The filter mechanism 7 includes a coarse filter screen and a differential pressure fine filter screen. The backwash mechanism 10 is fitted on the outside of the differential pressure fine filter screen. Pressure transmitters 11 are install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com