Boron-phosphorus-silicon glass film reflow method

A borophosphosilicate glass and dry reflow technology, which is applied in the field of borophosphosilicate glass film formation, can solve problems such as affecting the process and short circuit, and achieve the effect of shortening the time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

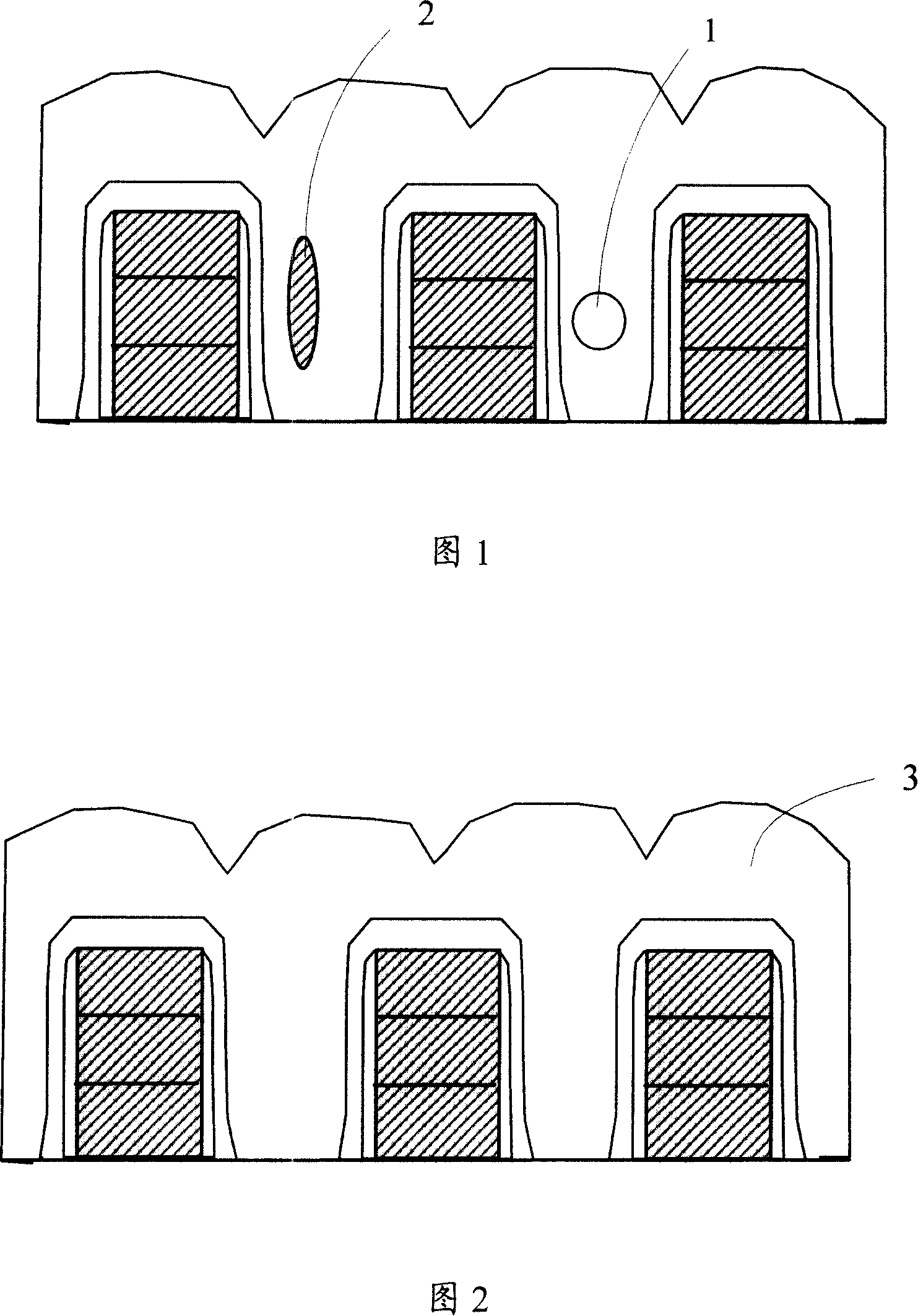

[0010] Put the wafer deposited with borophosphosilicate glass film (BPSG) 3 into the furnace tube, first perform dry reflow (DryReflow), pass nitrogen gas and heat at the same time, the borophosphosilicate glass film 3 is softened and reflowed under the action of nitrogen and temperature , when the temperature rises to the predetermined temperature for 5 minutes to 15 minutes, the nitrogen input is stopped, and the borophosphosilicate glass film 3 is reflowed to form, but due to uneven reflow, some voids are formed in the middle of the borophosphosilicate glass film.

[0011] Then carry out wet reflow (Wet Reflow), keep the temperature constant when feeding nitrogen, and feed hydrogen and oxygen at the same time, hydrogen and oxygen are used as catalysts, and under the effect of high temperature, the inside of the borophosphosilicate glass membrane 3 starts to flow, Simultaneously start infiltration from the upper and lower layers of the borophosphosilicate glass membrane 3, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com