Knife latch needle for pile fabric jacquard circular knitting machine

A technology of circular knitting machine and knife tongue, applied in knitting, textile and paper making, etc., can solve the problems of restricting the fabric structure, and achieve the effect of enriching the surface three-dimensional effect and reasonable overall structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

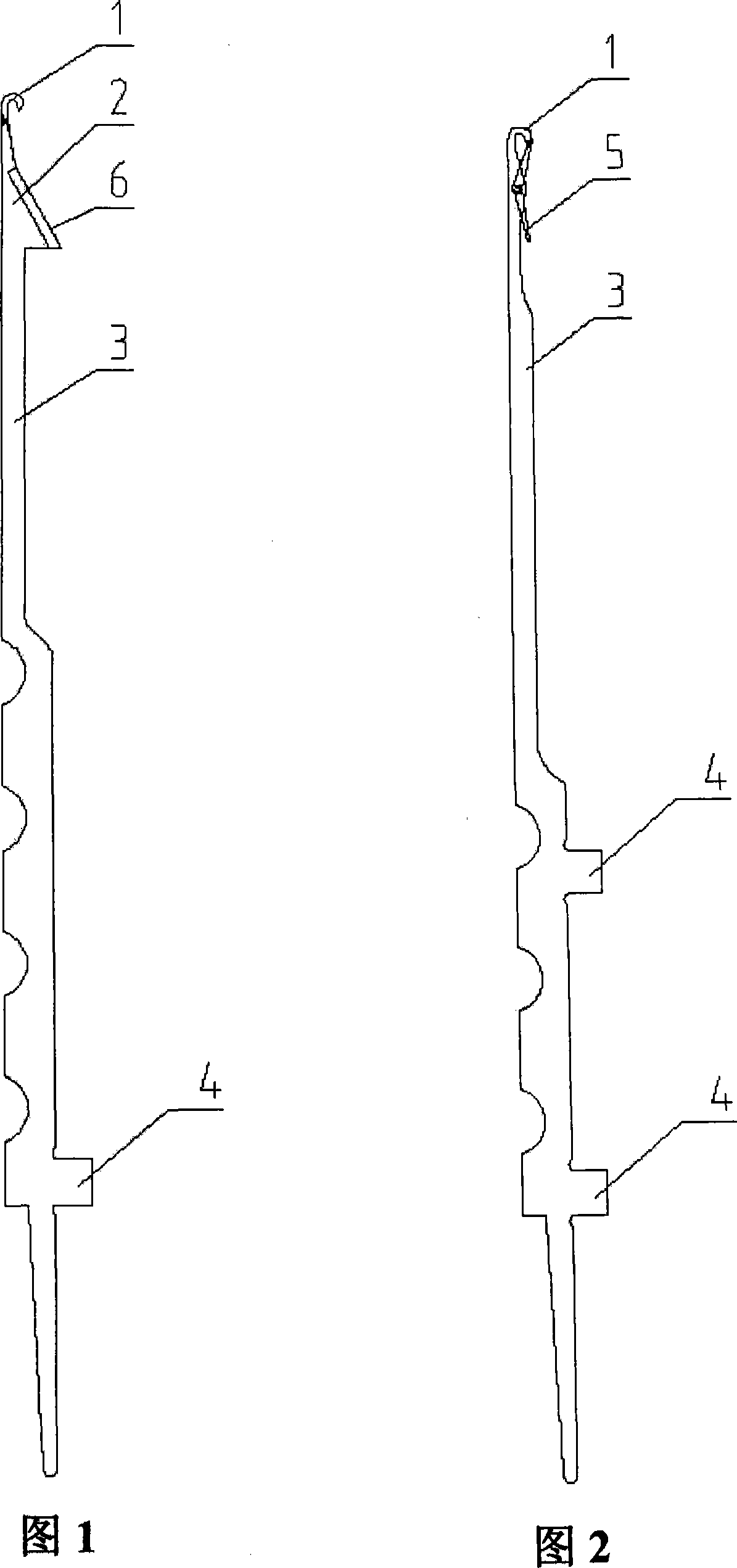

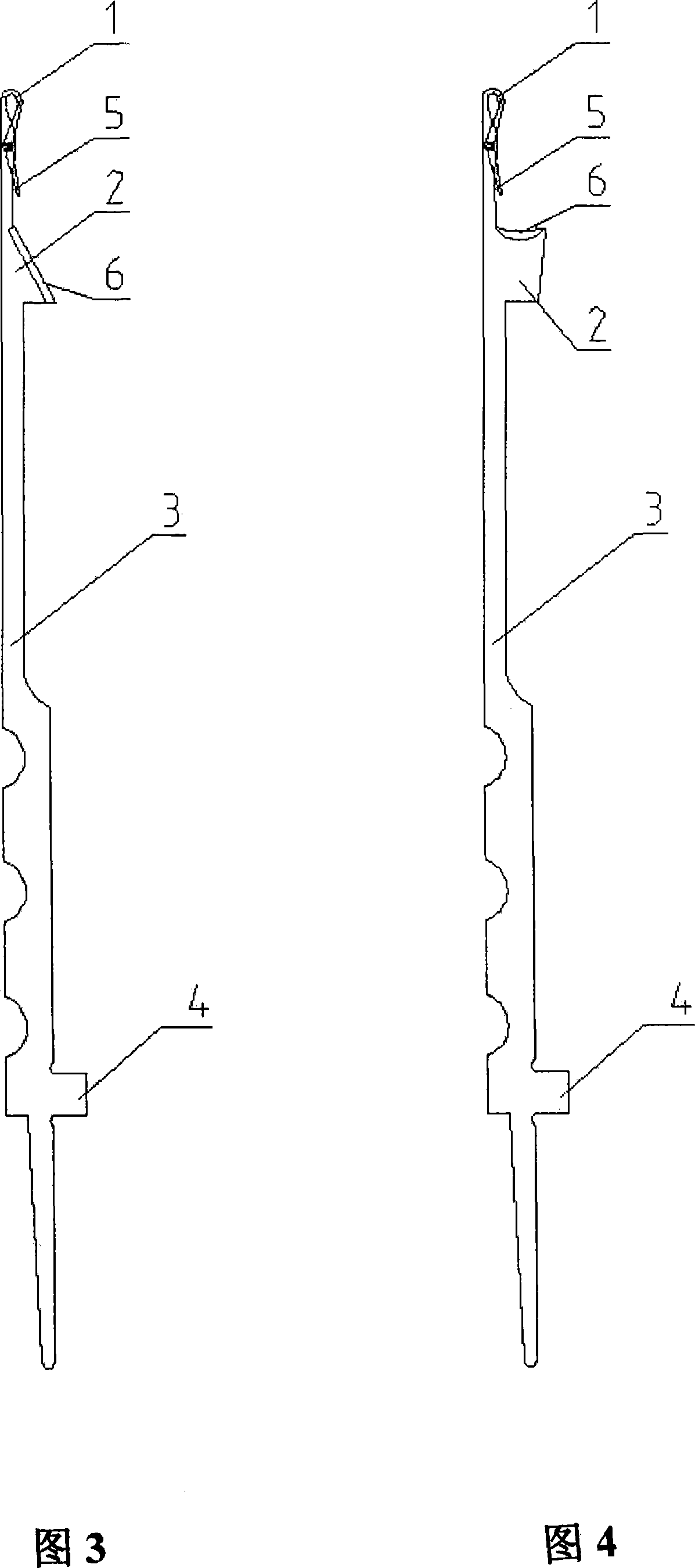

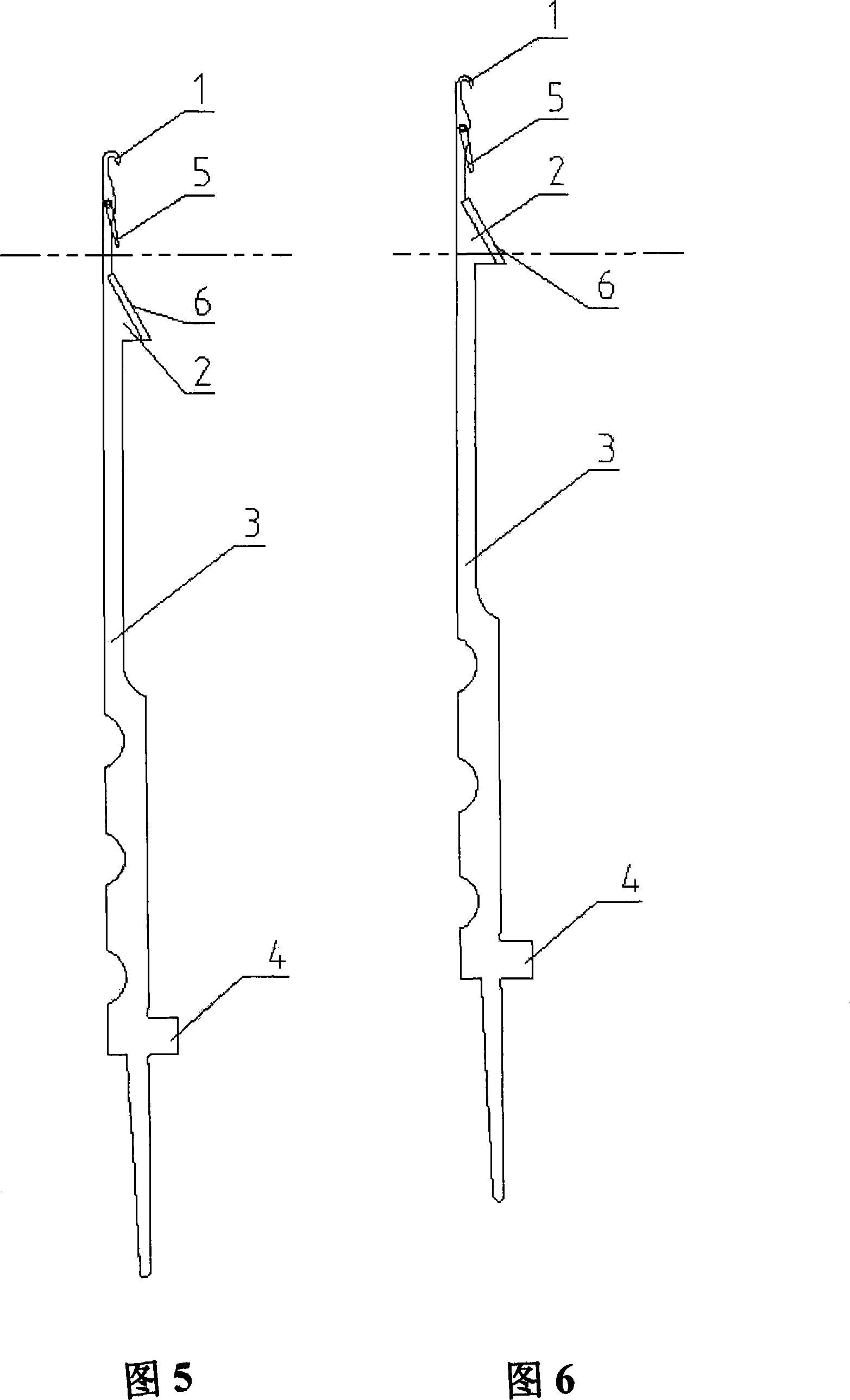

[0013] The present invention mainly consists of a needle body 3, a needle butt 4 placed at the bottom of the needle body 3, a needle hook 1 with a latch 5 placed at the top of the needle body 3, a needle knife 2 with a cutting edge 6, and the like. The needle knife 2 can be in a conical structure, and the cutting edge 6 is on the conical surface; it can also be in a trapezoidal or square structure, and the cutting edge 6 is on a right-angled surface adjacent to the needle latch 5 .

[0014] When in use, the present invention is embedded in the needle groove of the needle cylinder of the loop-cut pile jacquard knitting machine, and the jacquard jack cams are composed of two cams, a low cam and a high cam. Under the action of the needle selector, the needle lifter cam and the needle presser cam, the latch needle moves up and down in the needle groove according to the requirements, so as to achieve the two effects of pulling loops or cutting velvet. The height of the needle jacki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com