Method for centralized monitoring of continuous casting production working procedure of steel-smelting

A production process, centralized monitoring technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of unable to cover the production process, single monitoring method object, etc., to avoid conflicts, facilitate remote centralized management, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Overview

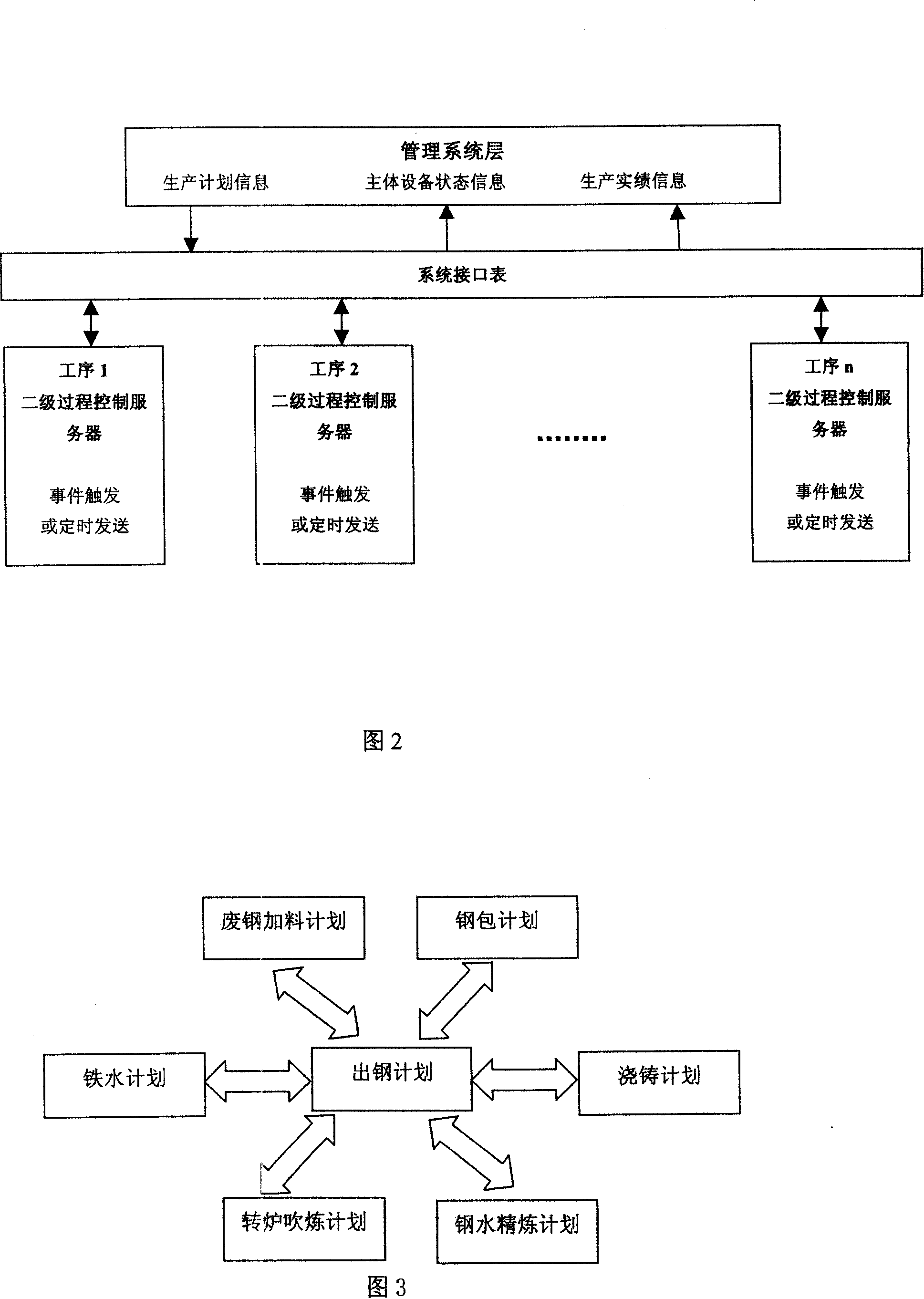

[0032] The centralized monitoring information of the present invention mainly includes: the status information of each production unit, reflecting the current status of the equipment (air factor, or in a stage in the production process), time information (at the start time of the production process and the planned end time) ), planned process route information (you can know all the process paths through which any process is processing substances and the next process to go), logistics information (ladle number, plan number and other identification information, as well as production performance information and quality information), Scheduling plan information and slab cutting and slab destination information.

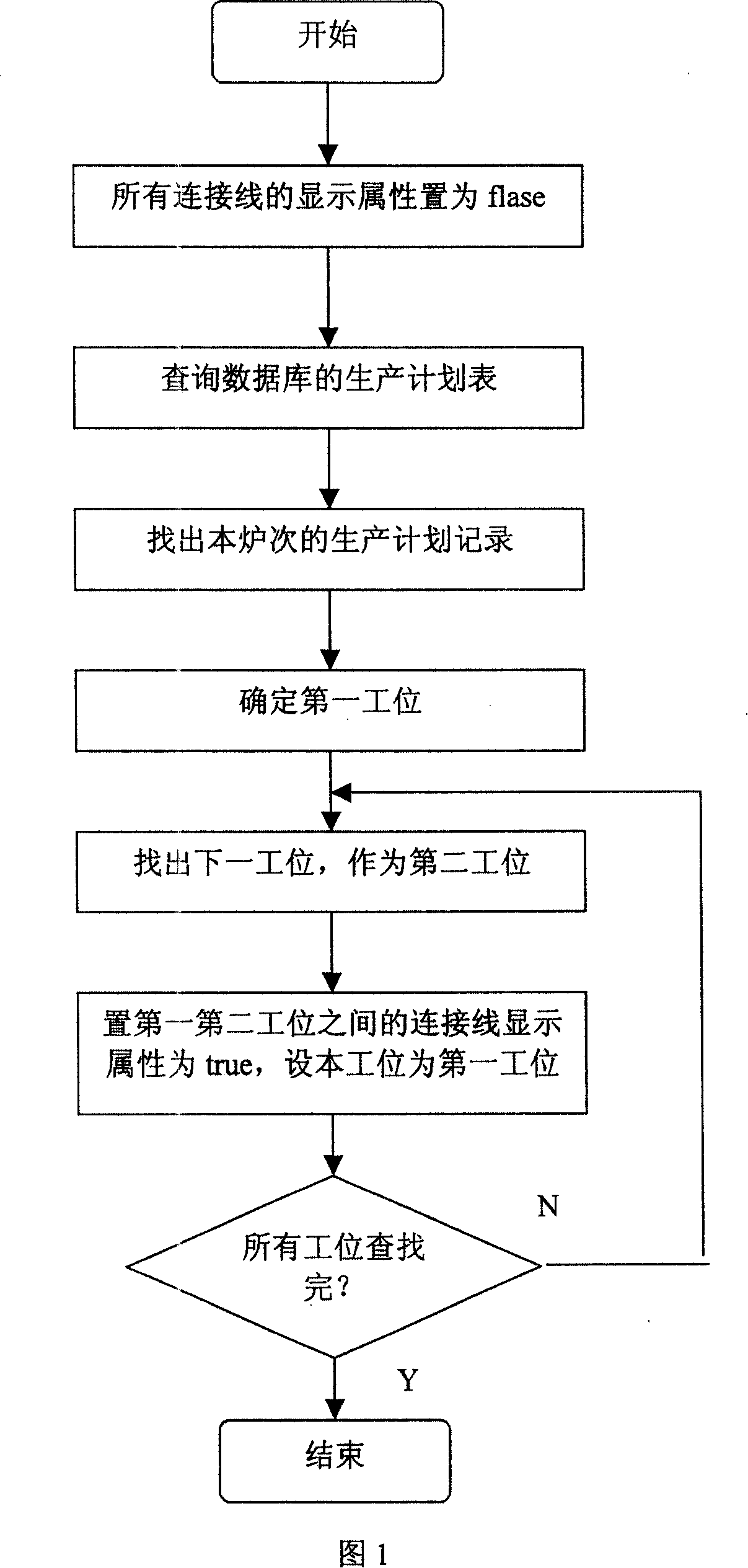

[0033] Implementation steps are introduced:

[0034] Implementation step 1: Establish a computer monitoring network, communicate with the process control computer system of each production unit, adopt standard TCP / IP protocol, and the process control system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com