Three-mark printing block group for automatic overprint of printing machine

A printing machine and marking technology, which is applied to printing machines, general parts of printing machinery, printing, etc., can solve problems such as detection of color leakage and false detection, multi-standard cumulative error, etc., and achieve high precision, flexible arrangement, and saving raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

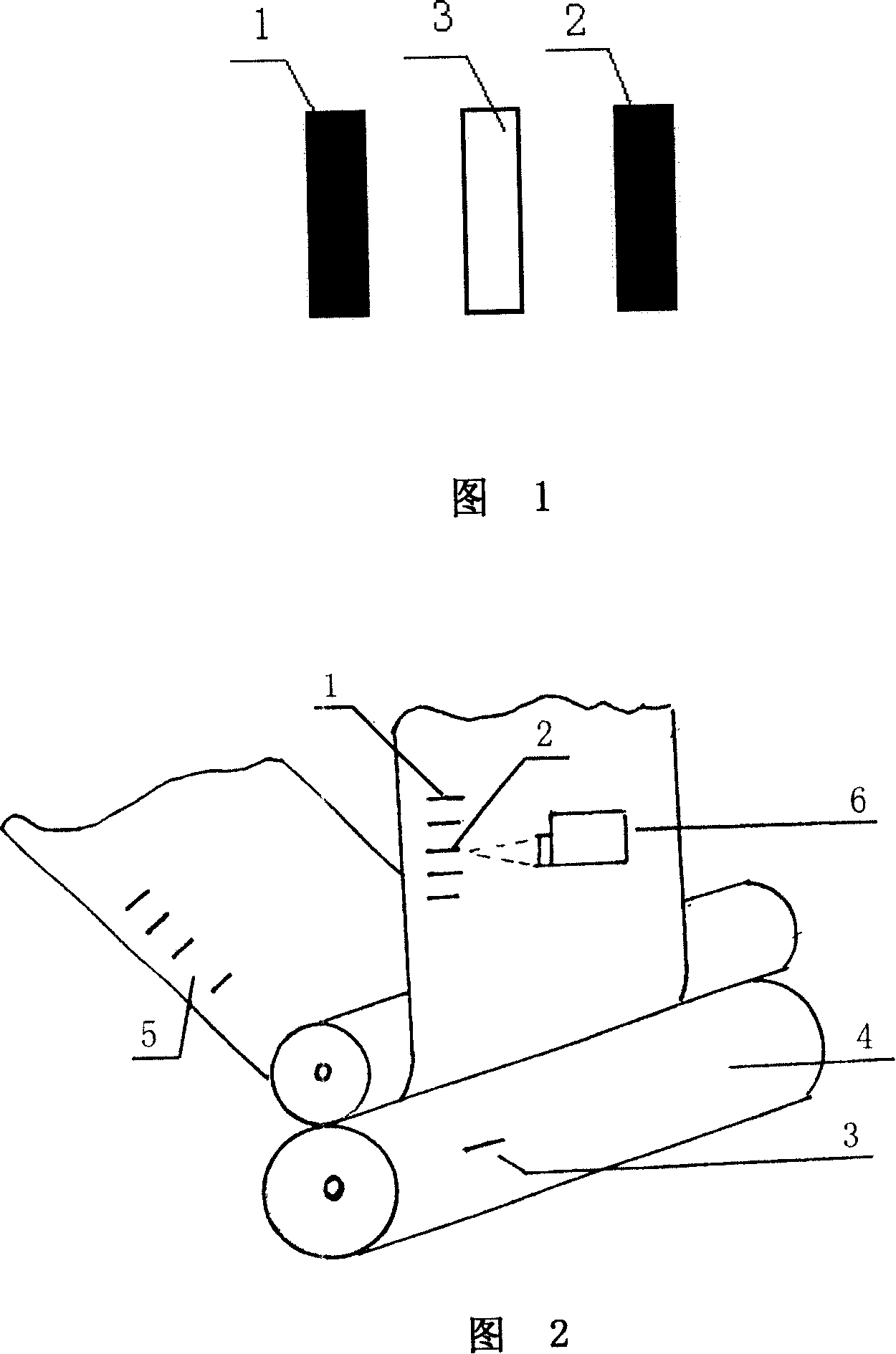

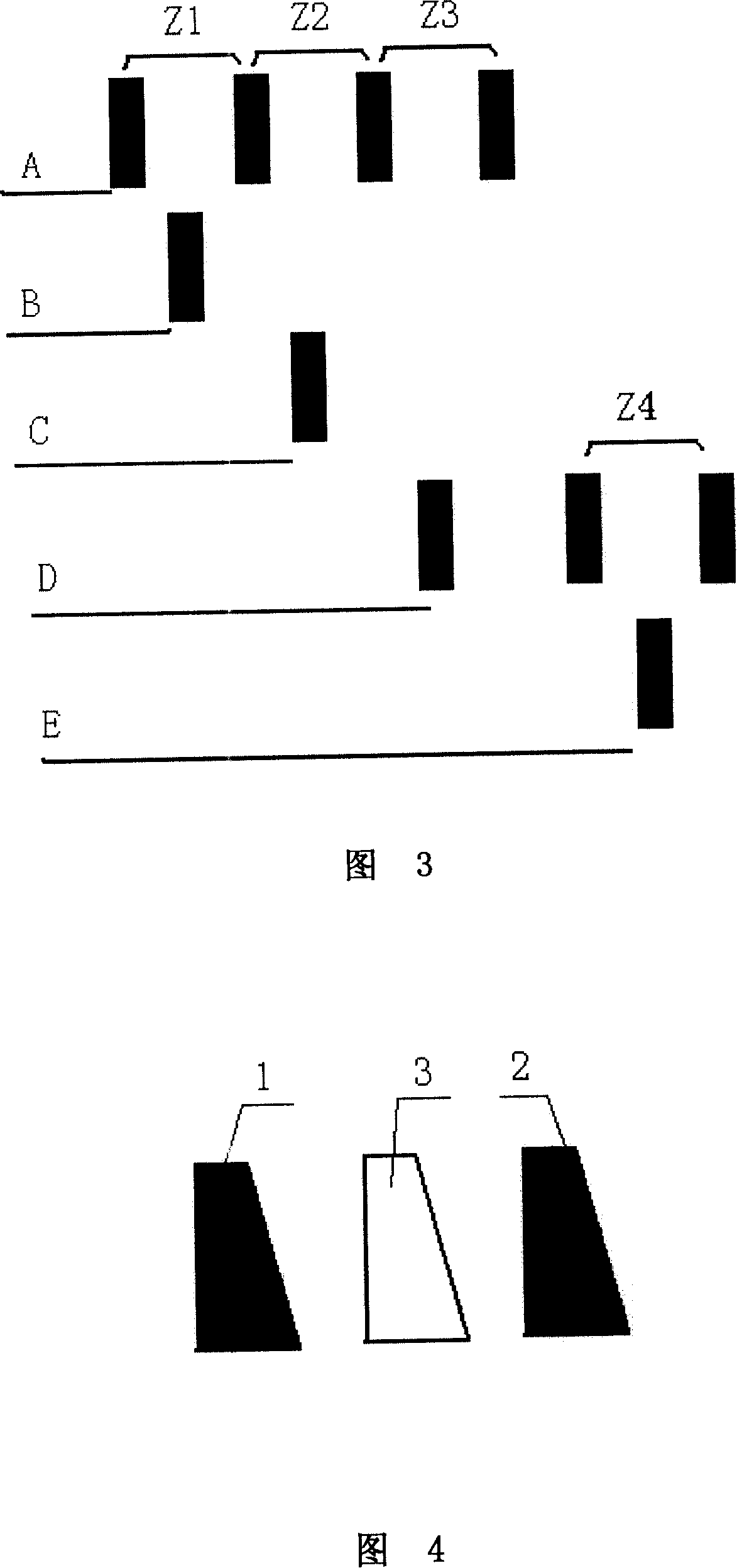

[0012] A three-mark printing plate set for automatic overprinting of a printing machine, including a reference color printing plate, a register color printing plate 4 and a scanning head 6. The reference color printing plate is provided with two reference color marks 1 and 2 at a certain distance along the circumferential direction. An overprint space 5 is formed between the two reference color marks, and an overprint color mark 3 that can be filled in the middle of the corresponding space is set on the overprint printing plate 4, and a three-mark unit group is formed by two reference color marks 1, 2 and the overprint color mark 3 .

[0013] In Figure 1, 1 and 2 are the two marks provided by the previous reference printing plate, thus forming an overprint space, and 3 is an overprint mark, which is made in the middle of the space.

[0014] In Fig. 2, 4 is an overprint printing plate, 3 is an overprint mark, and 6 is a single light point scanning head. The color mark is scann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com