Spider for goods train vehicle

A technology for railway wagons and vehicles, which is applied in the field of center discs, and can solve the problems that cannot be alleviated or eliminated, vehicle overturning, and snake-like instability, and achieve the effects of overcoming snake-shaped instability, increasing speed, and small frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

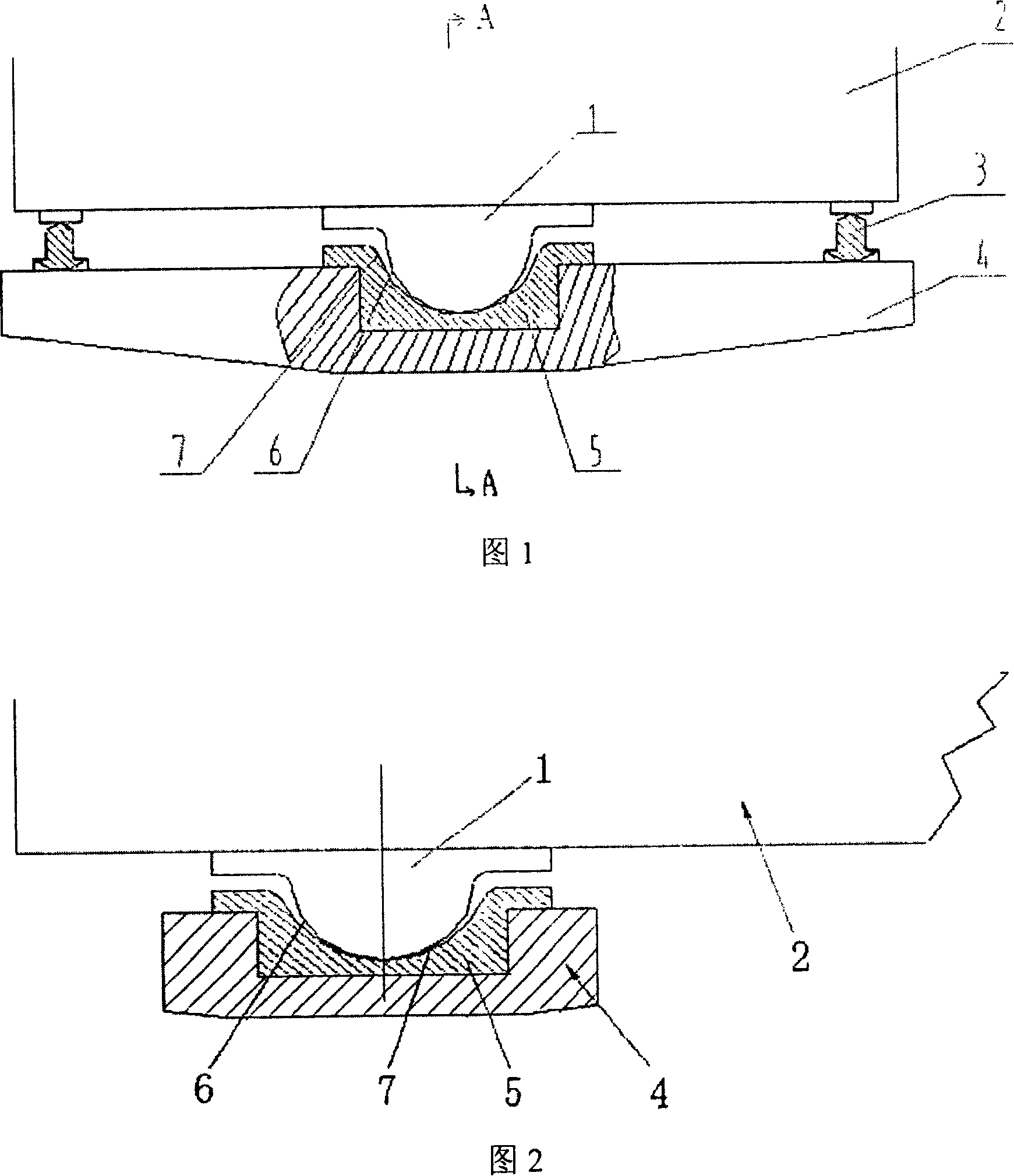

[0012] Referring to Fig. 1 and Fig. 2, the bottom of the upper center plate 1 is designed as a downwardly convex spherical surface 6, and above the lower center plate 5 there is a concave elliptical surface 7 matching with the upper center plate spherical surface 6. The sectional profile of the ellipse 7 shown in Figure 1 is the profile of the major axis direction, the sectional profile of the ellipse 7 shown in Figure 2 is the profile of the minor axis direction respectively, the minor axis radius of the ellipse 7 is the same as the spherical surface at the bottom of the upper center plate 6 with the same curve radius. The radius of the curve of the upper center plate 1 spherical surface 6 should not be too small, otherwise it will cause the load to be too concentrated and not conducive to the normal use of the vehicle, and if it is too large, it will lose its due effect. Preferably 115mm. The major axis radius of the ellipse 7 is 15-18 mm larger than the minor axis radius, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com