Cargo ship

A cargo ship and deck technology, applied in the direction of the hull, hull bow, hull deck, etc., can solve the problems of hindering cargo loading, unable to maintain the strength of the lifting deck, and simple movements, and achieve the effect of improving the degree of freedom, solid support and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

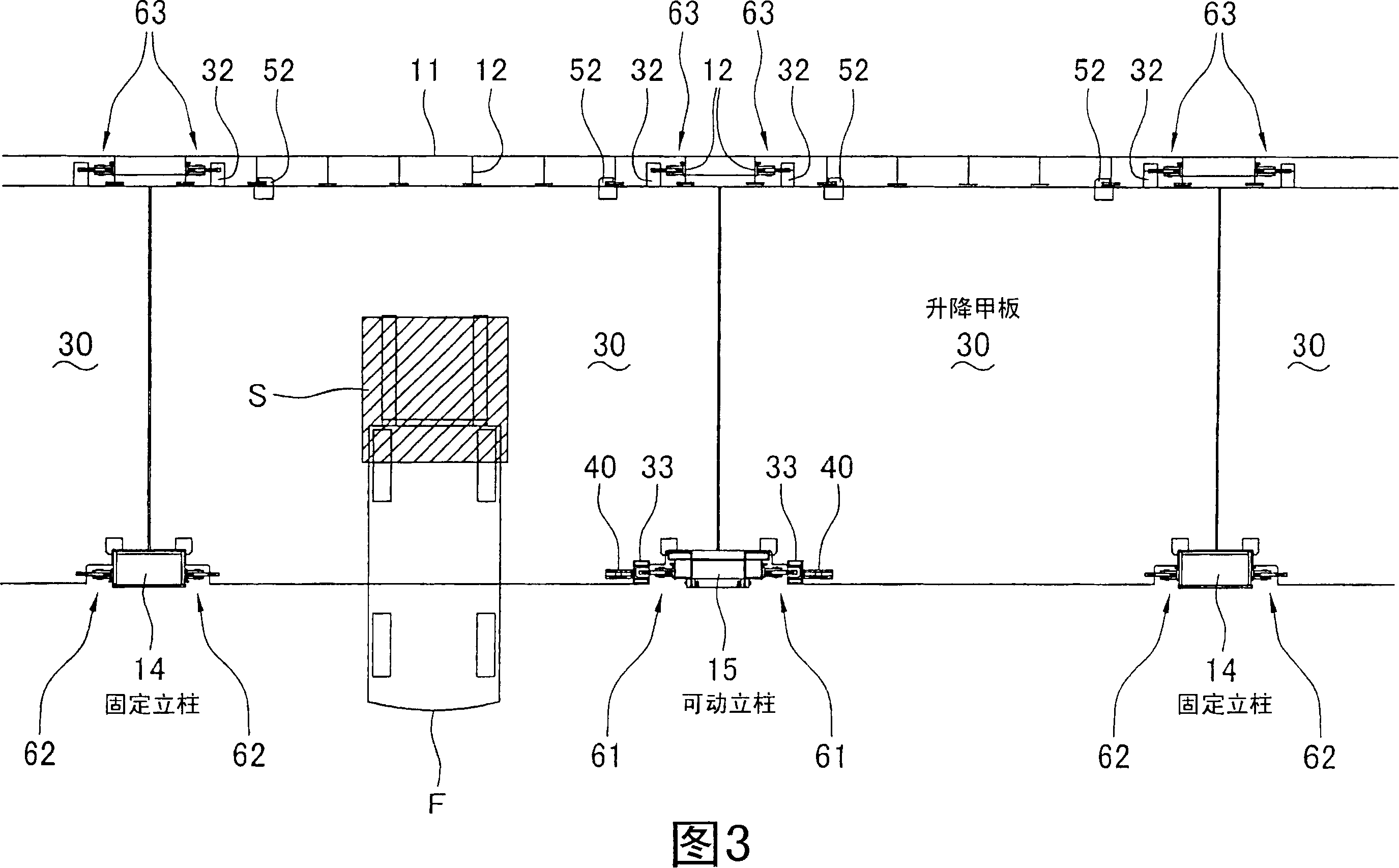

[0040] Embodiments of the present invention will be described below with reference to the drawings.

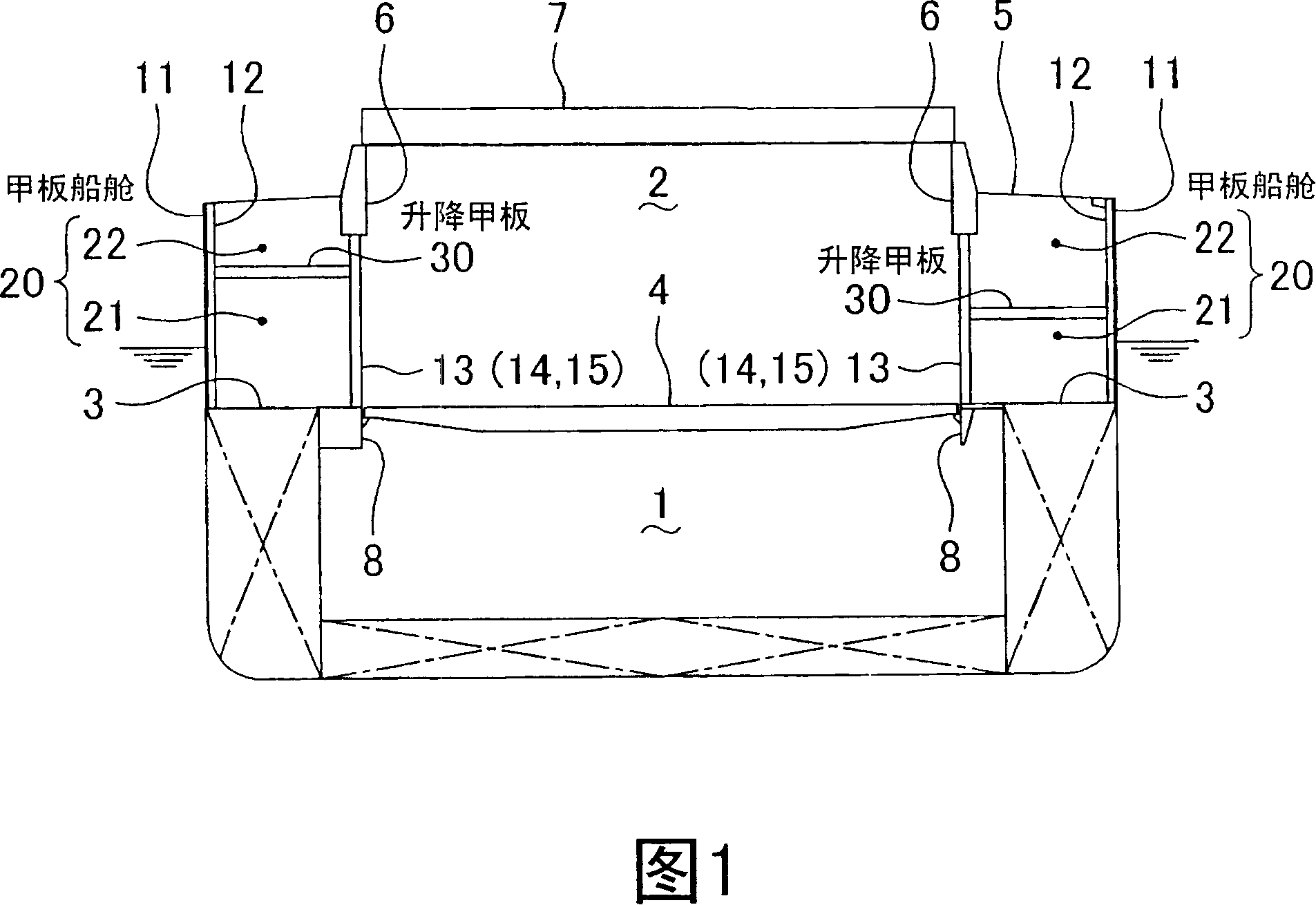

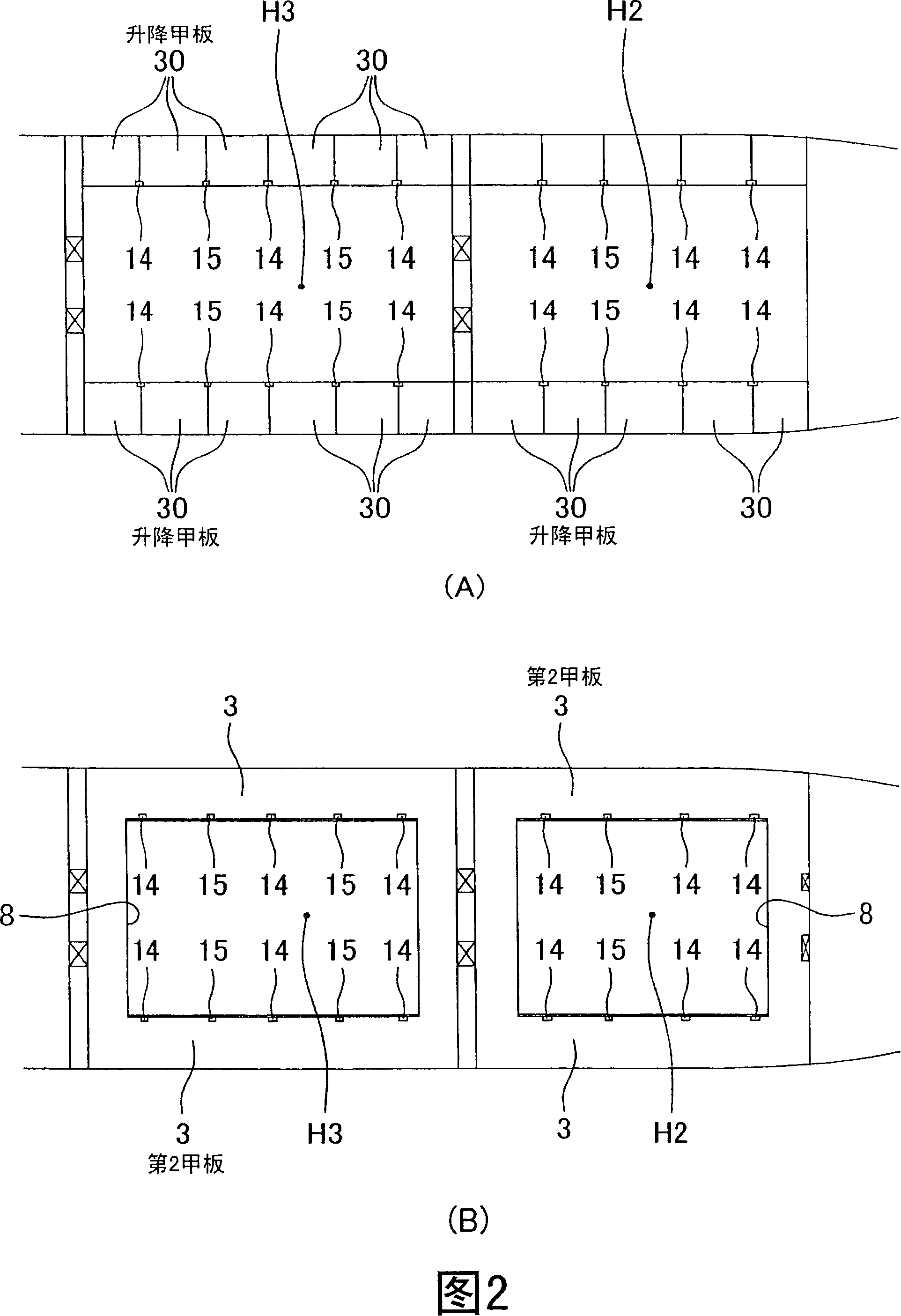

[0041]Fig. 1 is a longitudinal sectional view of a cargo ship according to an embodiment of the present invention. (A) figure of FIG. 2 is a top view which shows the elevating deck 30, (B) figure is a top view which shows the 2nd deck 3. As shown in FIG.

[0042] Among Fig. 1, 1 is the lower cabin, 2 is the upper cabin, 3 is the second deck, and 5 is the upper deck. The center portion of the upper deck 5 is opened and a hatch 6 is formed, and the center portion of the second deck 3 is also opened and a hatch 8 is formed. Furthermore, the hatch 6 of the upper deck 5 can be covered with an openable and closable hatch cover 7, and the hatch 8 of the second deck 3 is covered with a plurality of box-shaped hatch covers 4 which are detachably attached. The hatch cover 7 and the box hatch cover 4 are loading members having sufficient strength to support cargo. Therefore, cargo can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com