Method for real-time detection of vehicle load

A real-time detection and vehicle technology, applied in the field of detection, can solve the problems of low cost performance, limited quantity, single function, etc., and achieve the effect of low cost and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

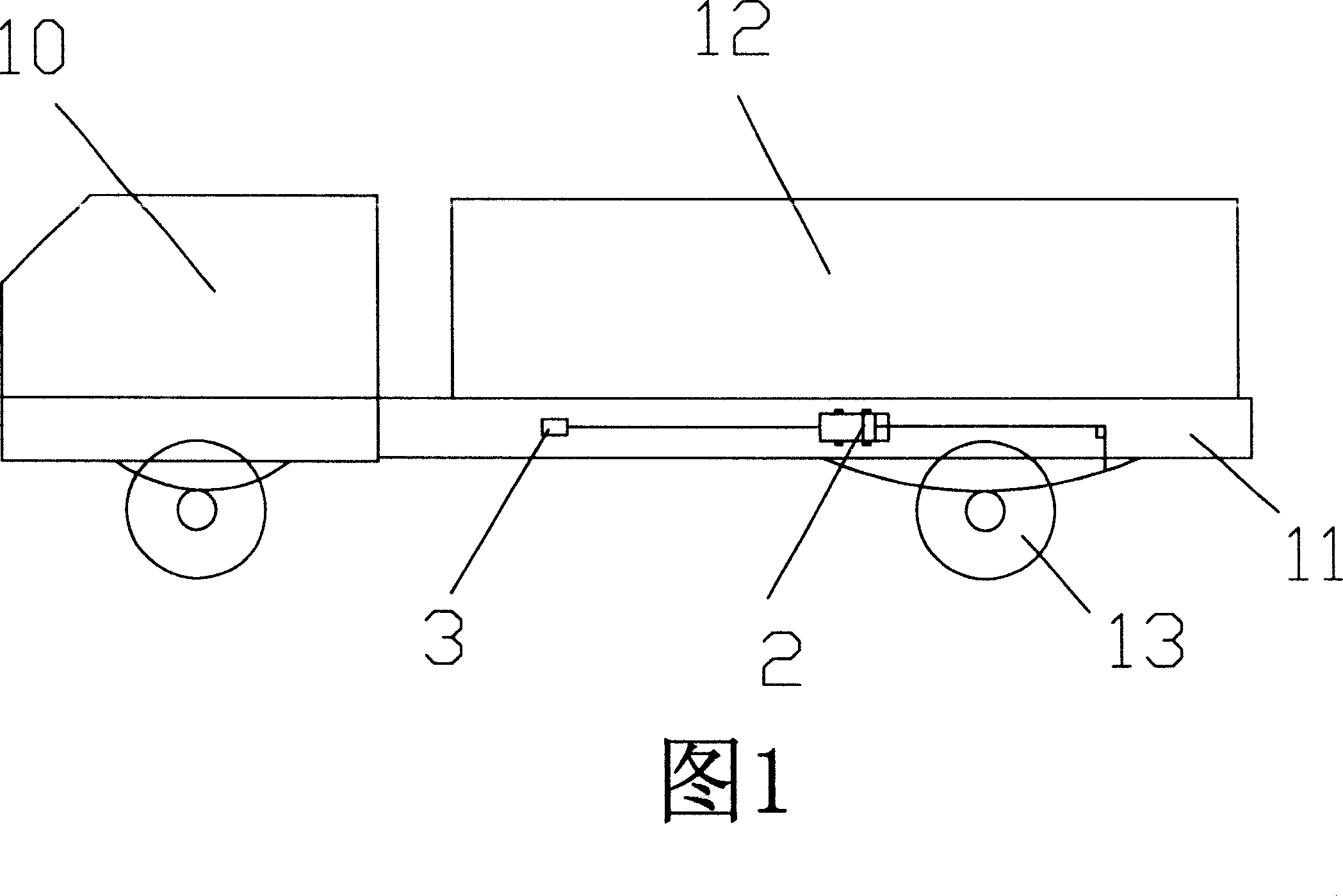

[0052] Referring to the accompanying drawings, a method for real-time detection of vehicle load according to the present invention includes two processes of calibration and real-time detection:

[0053] In the calibration process, it includes the following steps:

[0054] Step a. Calibrate the relationship between the output voltage of the load cell and the displacement of the sensor;

[0055] Step a1. Apply an external force to cause a displacement change of the load sensor to be installed on the vehicle, measure the value of the displacement, and read the voltage data output by the load sensor corresponding to the displacement through the load detector to obtain the output of the load sensor. A set of correspondence between the voltage data and the displacement value;

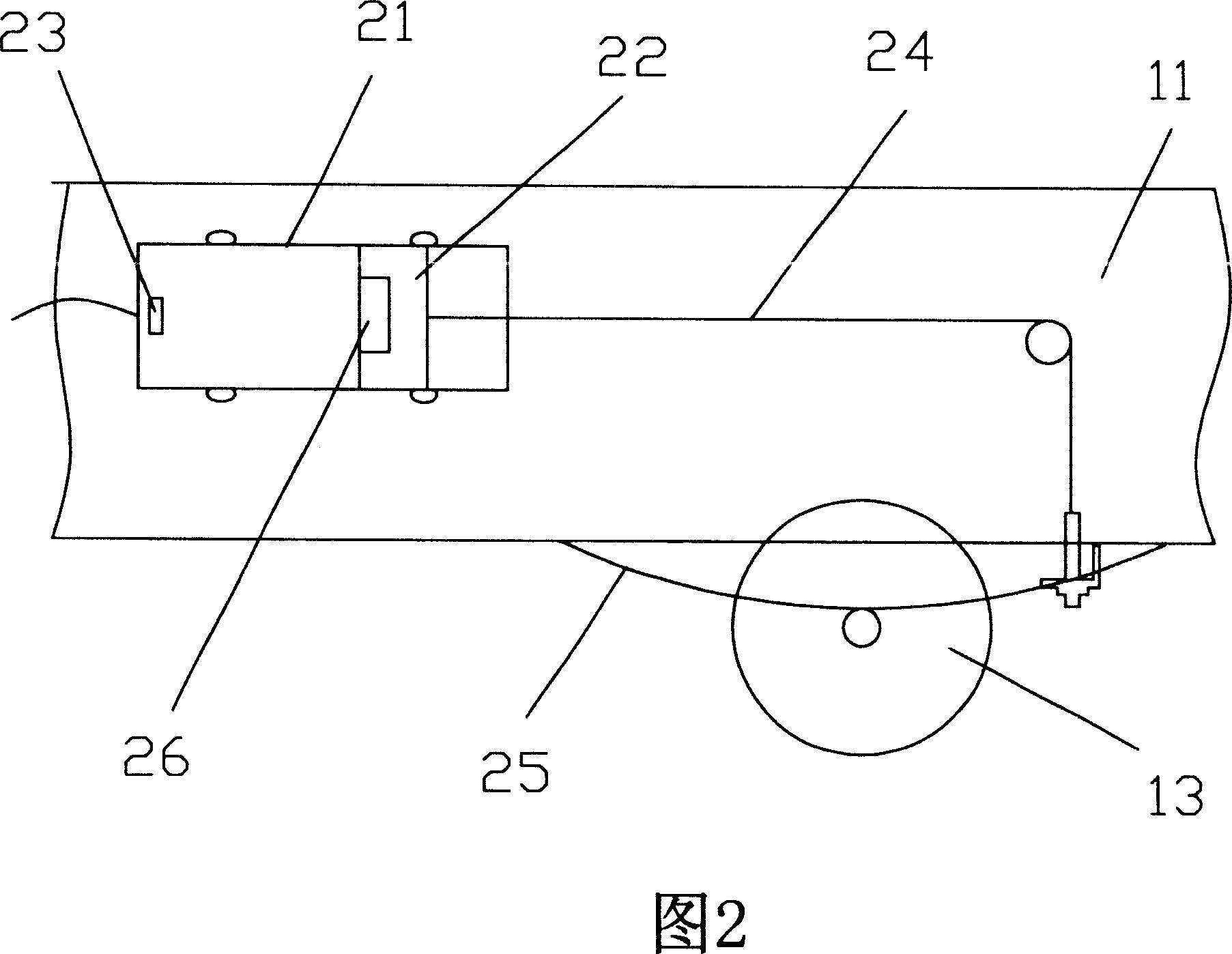

[0056] As shown in Fig. 1 and Fig. 2, four load sensors 2 are installed in total, 2 front wheels and 2 rear wheels respectively; For loading goods, the load sensor 2 includes a circular steel cylinder 21, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com