Inductor

An inductor and electrode technology, which is applied in the field of surface mount inductors, can solve the problems of limiting the miniaturization of products and insufficient use of product space, and achieve the effect of low profile, improved electrical characteristics, and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

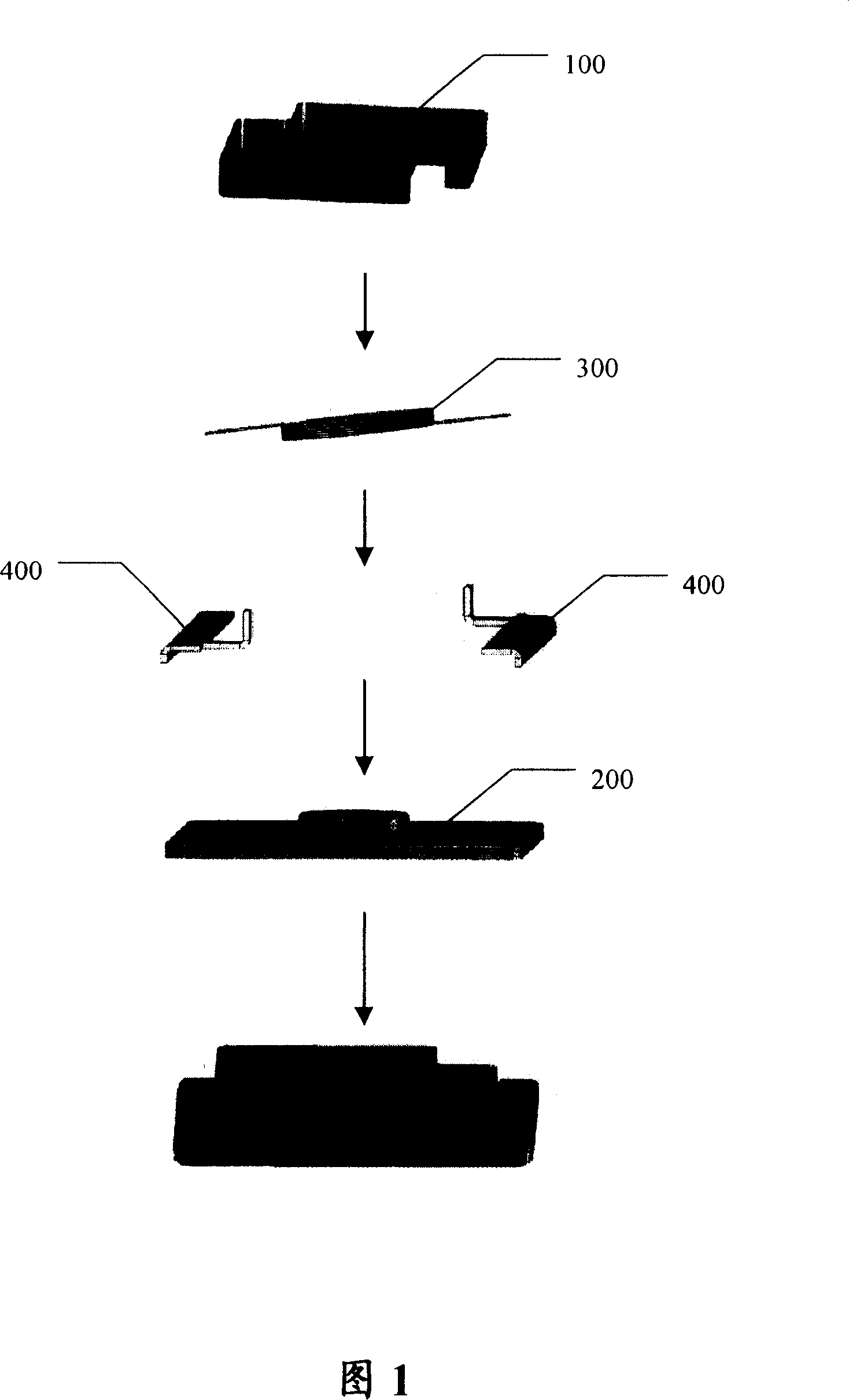

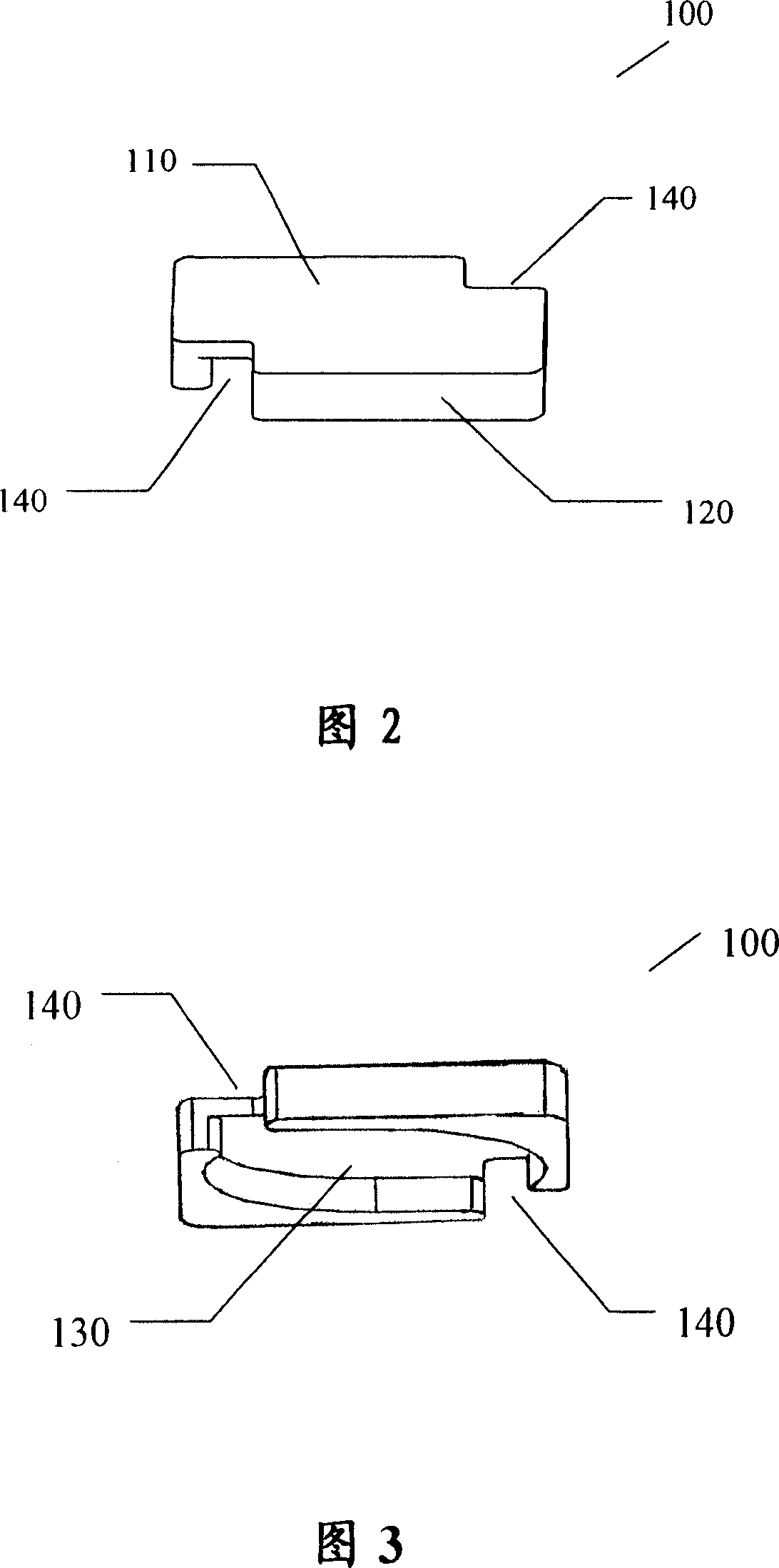

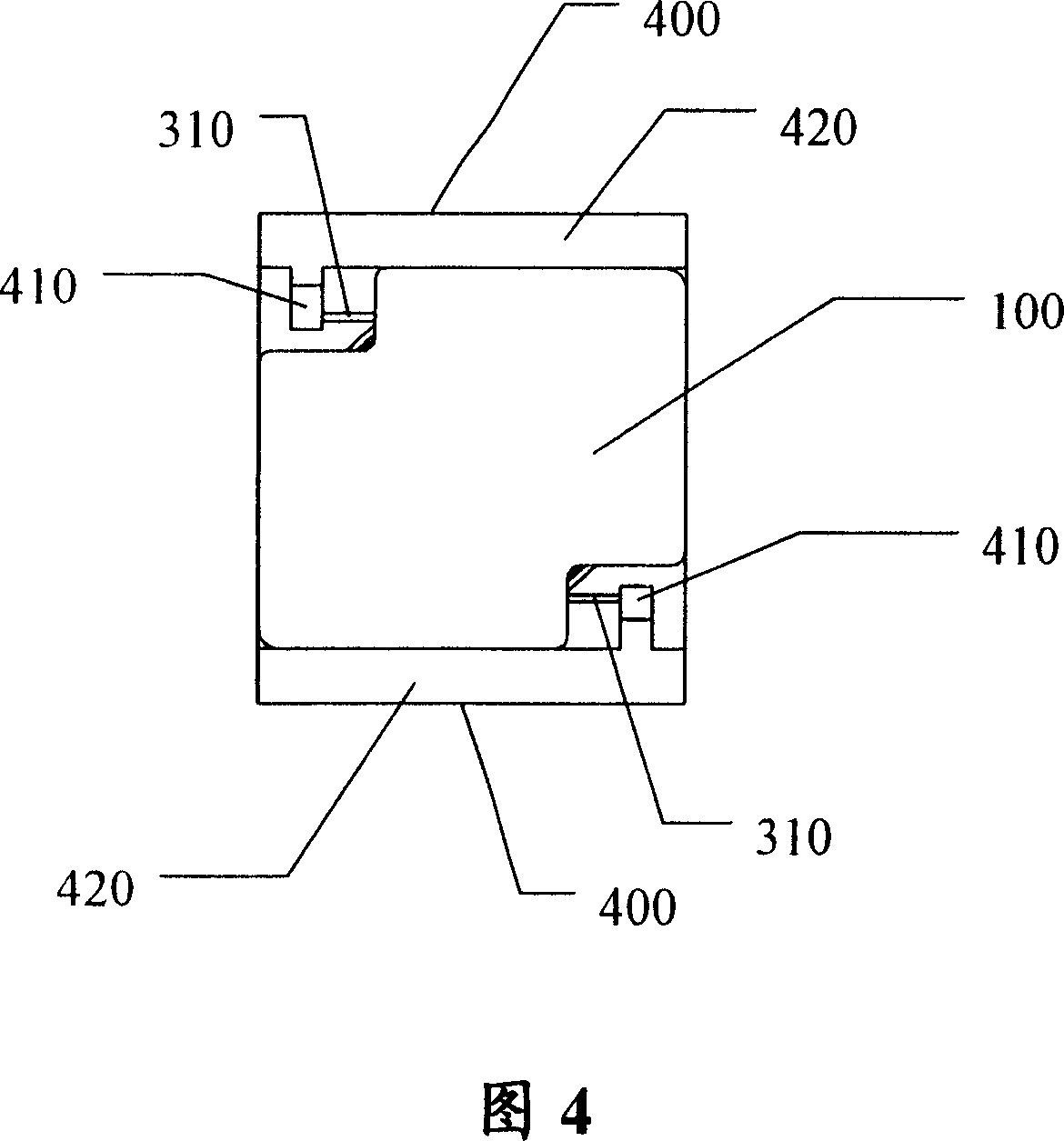

[0030] Embodiment 1: As shown in FIG. 1 , the inductor according to this embodiment includes: a flat rectangular parallelepiped magnetic cap 100 , a substrate 200 , a coil 300 and two electrodes 400 . As shown in FIG. 2 , the magnetic cap 100 is composed of a top wall 110 and a side wall 120 for forming a cylindrical cavity 130, see FIG. The two notches 140 passing through the side wall 120 and the top wall 110 of the magnetic cap, see FIG. 2 and FIG. 3 , are used to lead out the two lead ends 310 of the coil 300 to connect with the electrode 400 , see FIG. 4 . As shown in Figure 5, a cylindrical magnetic core 210 corresponding to the cavity 130 of the magnetic cap 100 is provided on the substrate 200, preferably the cylindrical magnetic core 210 is perpendicular to the substrate 200 and integrally formed with the substrate 200; the coil 300 has two lead ends 310 , and the coil 300 can be sleeved on the magnetic core 210 . As shown in Figure 5, the electrode 400 includes a co...

Embodiment 2

[0034] Embodiment 2: As shown in FIG. 7, the difference between the inductor of this embodiment and the inductor of Embodiment 1 is that two cylindrical magnetic cores 210 are arranged on the substrate 200; the magnetic cap 100 is a flat cuboid Shaped, the side wall and the top wall of the magnetic cap 100 form a cavity that can accommodate two cylindrical magnetic cores 210 behind the coils 300 respectively; The notch 140 of the side wall and the top wall of the cap 100 .

Embodiment 3

[0035] Embodiment 3: As shown in FIG. 8 and FIG. 9, the inductor of this embodiment is similar to the inductor of Embodiment 1, and a cylindrical magnetic core 210 is arranged on the substrate 200; the magnetic cap 100 is a flat cuboid shape, The side wall and the top wall of the magnetic cap form a cylindrical cavity. However, the difference between the inductor of this embodiment and the inductor of Embodiment 1 is that there are notches penetrating through the side wall and the top wall of the magnetic cap at the four edges of the rectangular parallelepiped magnetic cap 100 respectively, wherein the The coil 300 connected to the magnetic core 210 has two windings, and the four lead ends of the coil 300 are led out from the four gaps respectively to connect with the four electrodes 400 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com