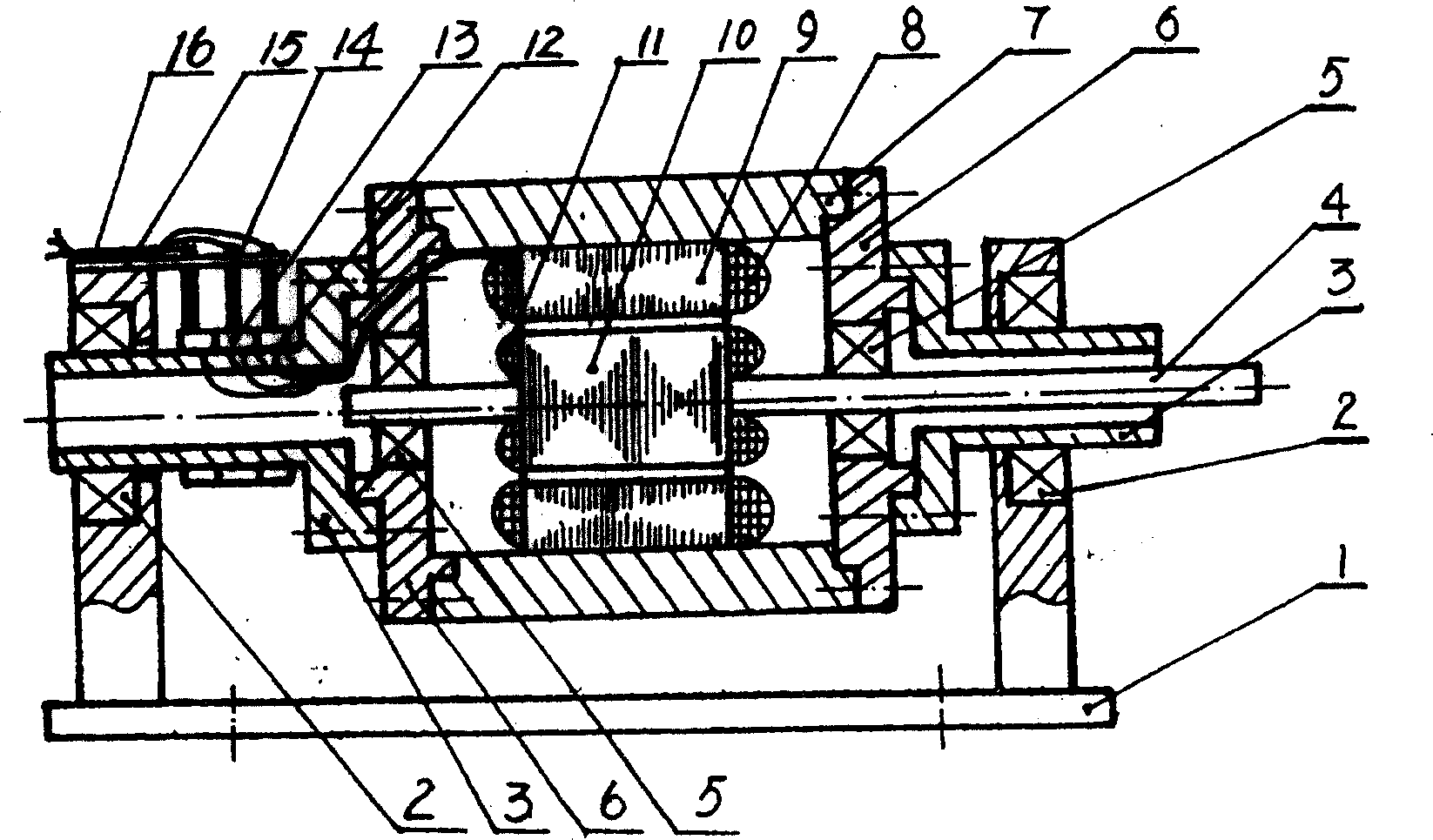

Double-rotating shaft electric motor

A dual-shaft and casing technology, applied in electrical components, electromechanical devices, electrical components, etc., can solve the problem of not being able to meet special requirements, and achieve the effect of improving efficiency and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0007] Embodiment: A double-rotating shaft motor, the outer rotor coil 8 is embedded in the slot of the outer rotor core 9, the outer rotor core is matched with the casing 7, the inner rotor coil 11 is embedded in the slot of the inner rotor core 10, the inner rotor Iron core 10 and coil 11 are set on the outer rotor iron core 9 and coil 8 with a small gap in between. The inner rotor shaft 4 is fixed on the end cover 6 through the inner rotor bearing 5, and the end cover 6 is fixed on the casing 7. The outer rotor One end of the pump 3 is fixed on the end cover 6, the other end is fixed on the base 1 through the outer rotor bearing 2, the brush holder 15 is fixed on the base 1, and the slip ring 13 connects the outer rotor shaft 3 and the slip ring 13 through the insulation 12. After being insulated, they are fixed on the outer rotor shaft 3, and the power supply is sent into the outer rotor coil 8 through the lead wire 16, the carbon brush 14 and the slip ring 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com