Casting pig blank inner bag slow fire stewpot

A slow cooker and cast iron technology, which is applied to special materials for cooking utensils, cooking utensils, household utensils, etc., can solve the problems of complex assembly of thermostats, poor thermal conductivity of iron products, and unusable pots, so as to achieve unbreakable , prevent heat leakage, enhance the effect of wall thickness rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

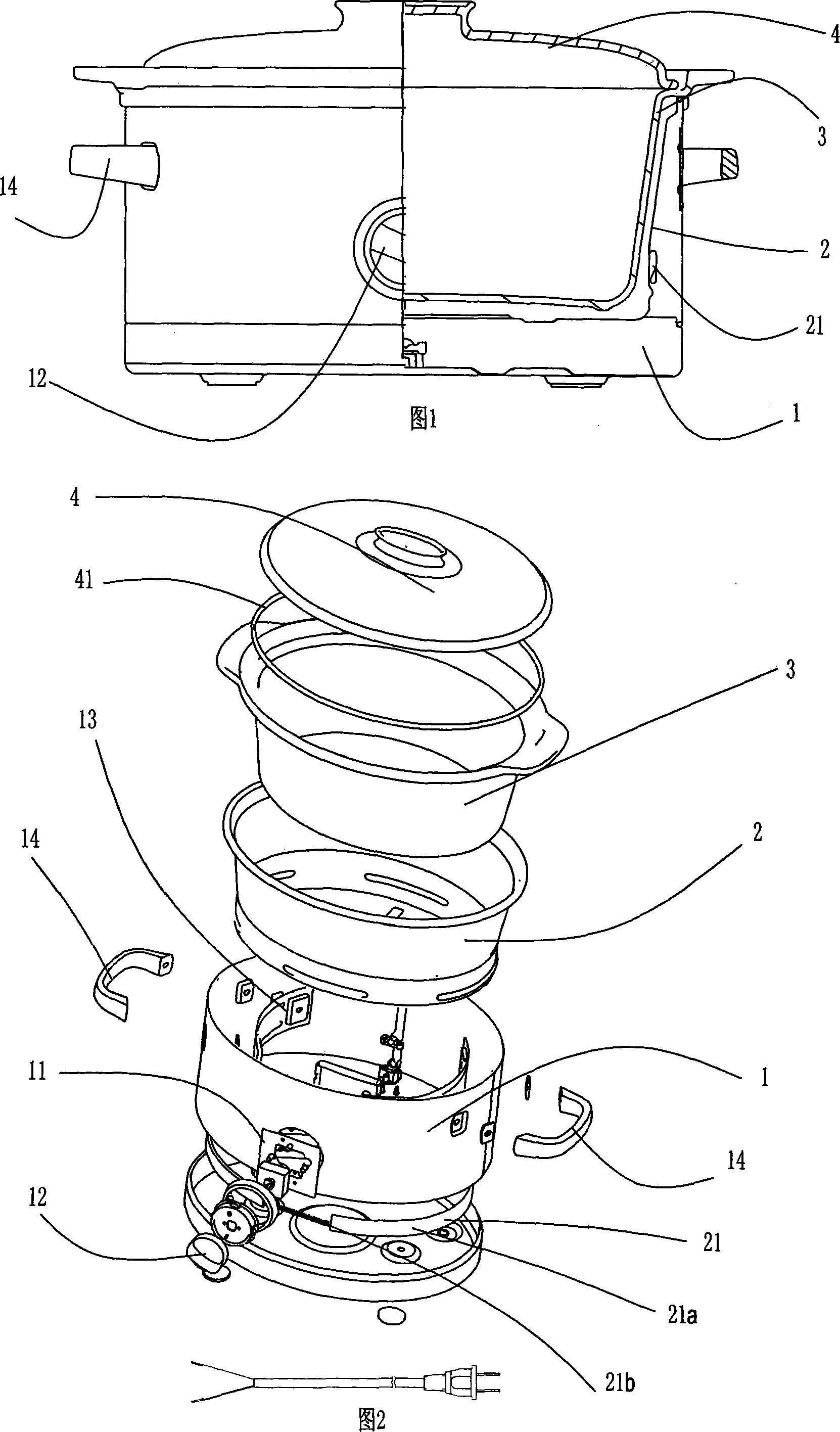

[0014] The embodiment shown in Fig. 1 and Fig. 2, reference number description: housing 1, printed circuit board 11, knob 12, handle bracket 13, handle 14, aluminum courage body 2, heating ring 21, annular body 21a, extension spring 21b, unit cast iron billet liner 3, glass cover 4, rubber ring 41.

[0015] The slow cooker with cast iron billet liner according to the embodiment of the present invention comprises a shell 1, an aluminum pot 2 is fastened in the upper cavity of the shell 1, a unit cast iron billet liner 3 is embedded in the inner cavity of the aluminum pot body 2, and a unit cast iron billet liner is embedded. 3. The inner core is a concave cast iron billet, which is formed by casting or rolling. The entire outer surface of the cast iron billet is uniformly coated with at least one layer of enamel paste, and the enamel paste is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com