Line type ultrasonic wave bottle cleaning machine

An ultrasonic wave and bottle washing machine technology, applied in the field of linear ultrasonic bottle washing machines, can solve the problems of unsatisfactory bottle feeding method and cleaning quality, high difficulty in sanitation cleaning inside the box, and large floor space. Small, simple structure, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

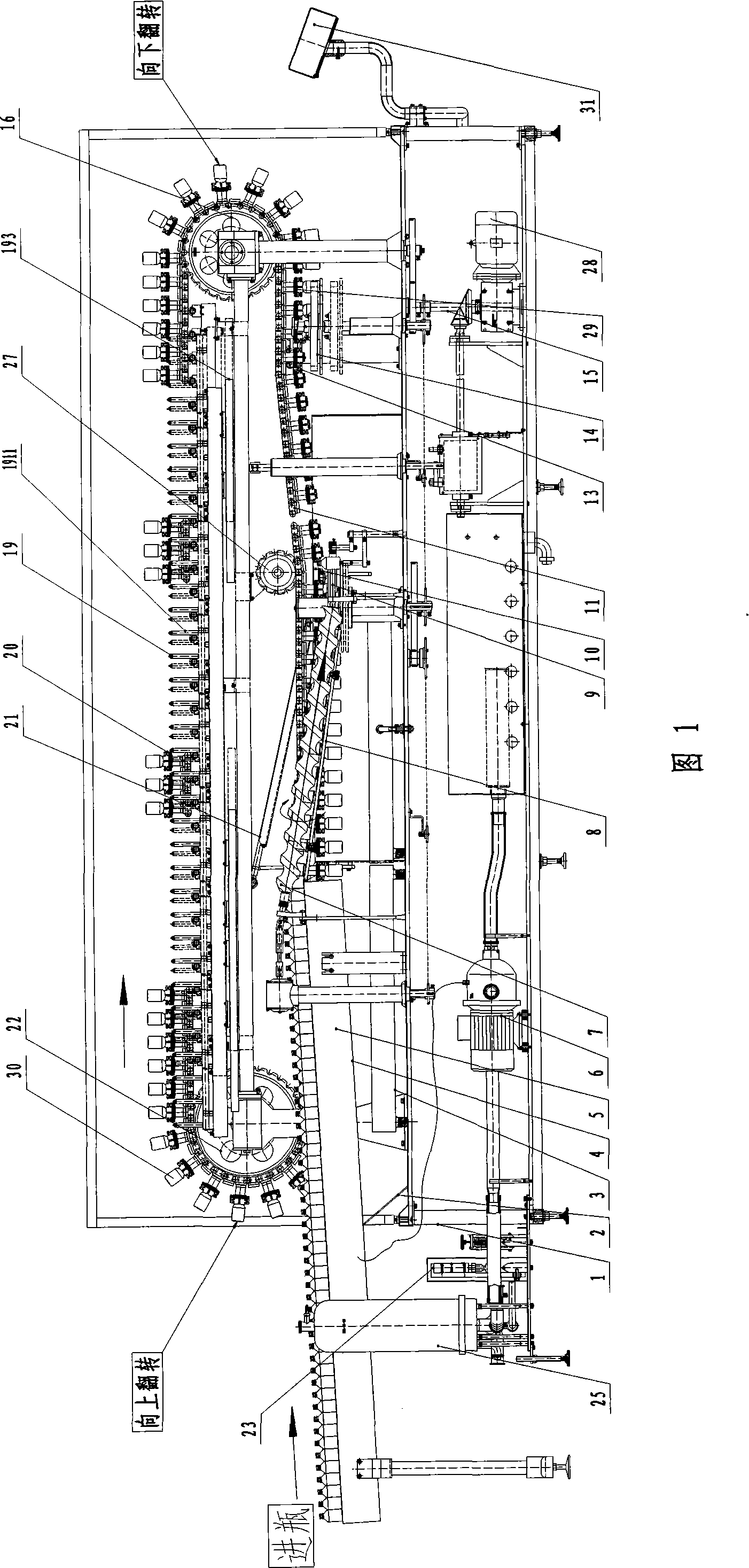

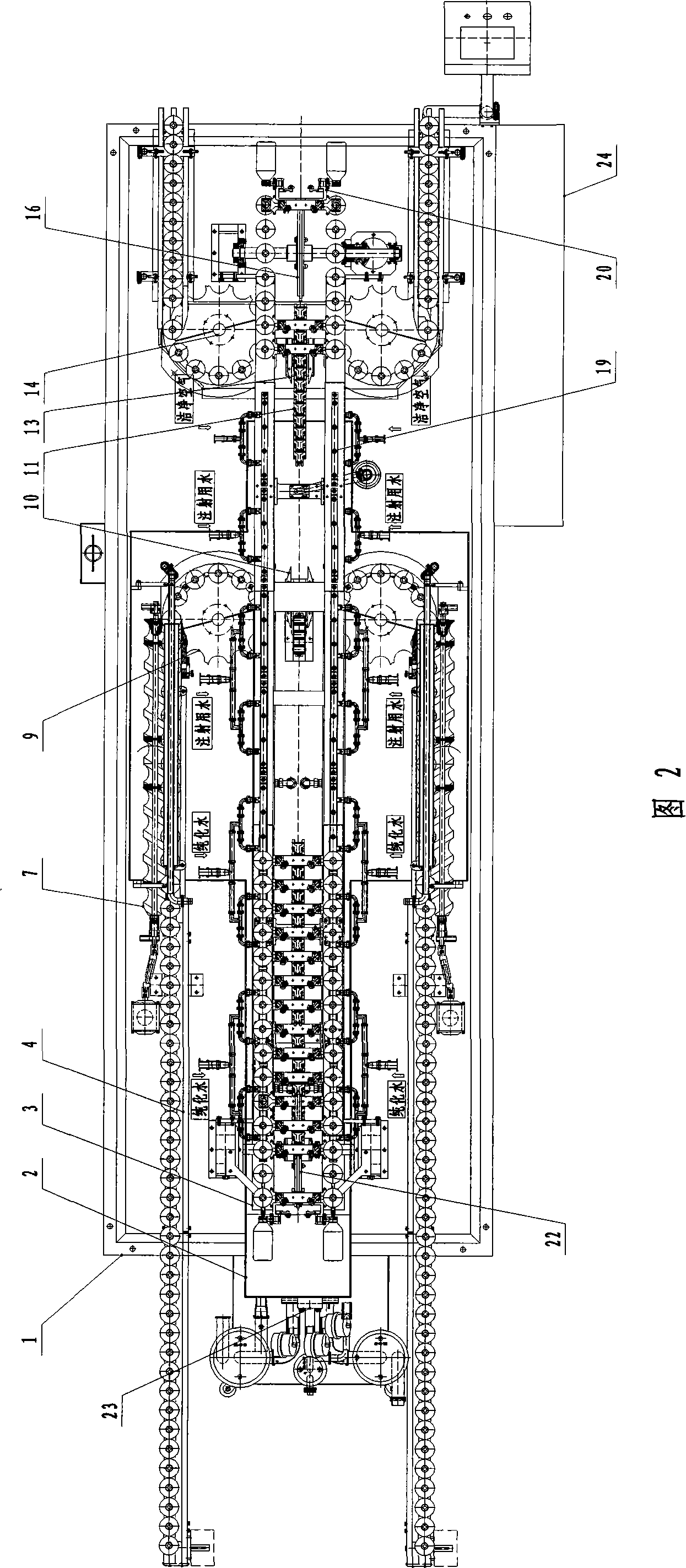

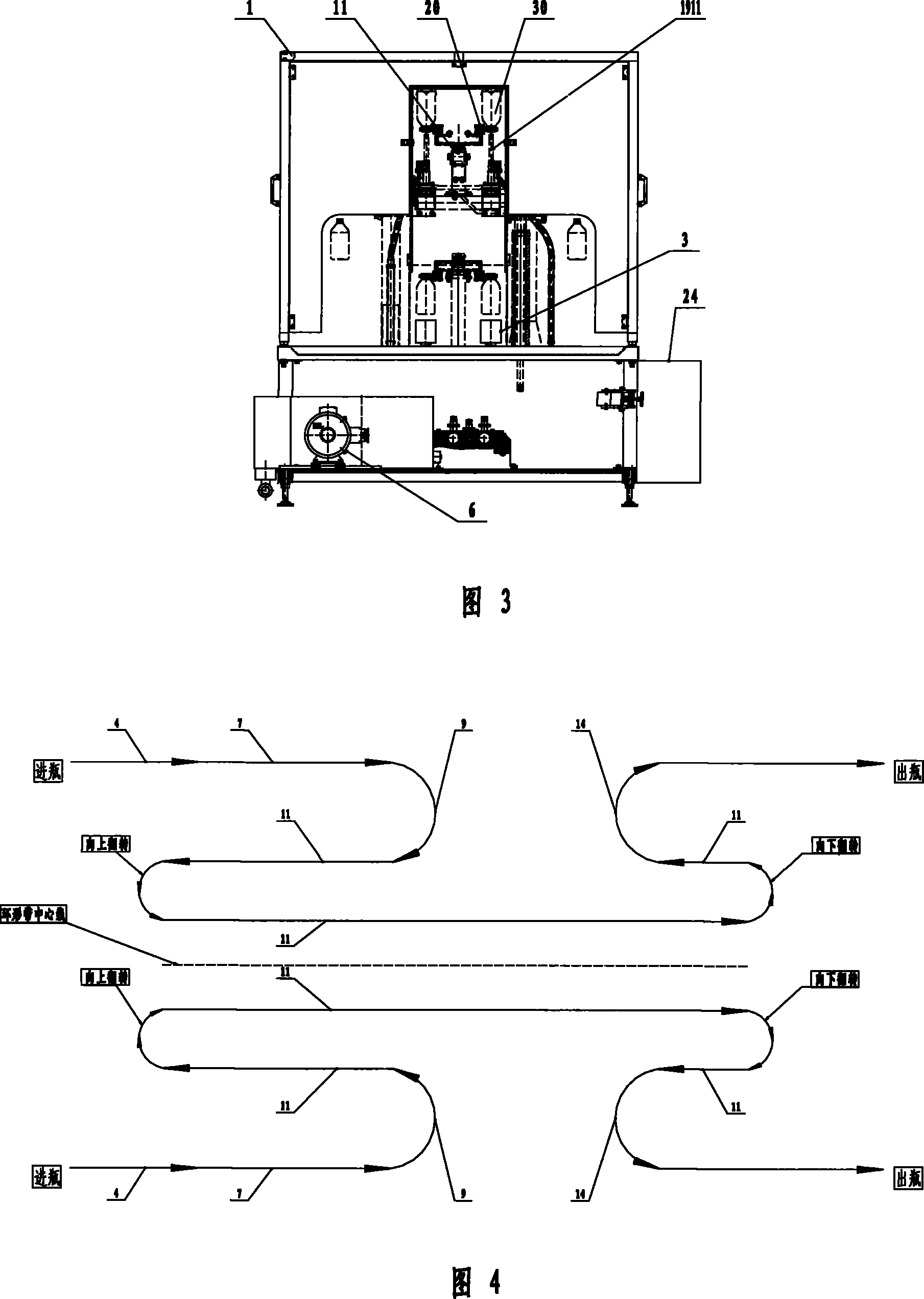

[0065] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0066] As shown in Figure 1, Figure 2, Figure 3 and Figure 4, the linear ultrasonic bottle washing machine of the present invention comprises a frame 1, a water and air supply device 25 and a water tank 2 installed on the frame 1, an ultrasonic bottle washing machine Device 3, bottle feeding mechanism 4, separate bottle feeding auger mechanism 7, bottle feeding dial mechanism 9, circular conveying mechanism 11, tracking flushing mechanism 19, bottle clamping manipulator 20, bottle discharging dial mechanism 14, electric control box 24 and The power unit 28, the water tank 2 is located under the circular conveying mechanism 11, the ultrasonic bottle washing device 3 is installed in the water tank 2 and is located on both sides of the bottom of the circular conveying mechanism 11, the bottle feeding mechanism 4 separates the bottle feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com