Dust collector

A dust collection device and dust technology, applied in the direction of dust removal, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problem of high replacement cost of filter bodies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

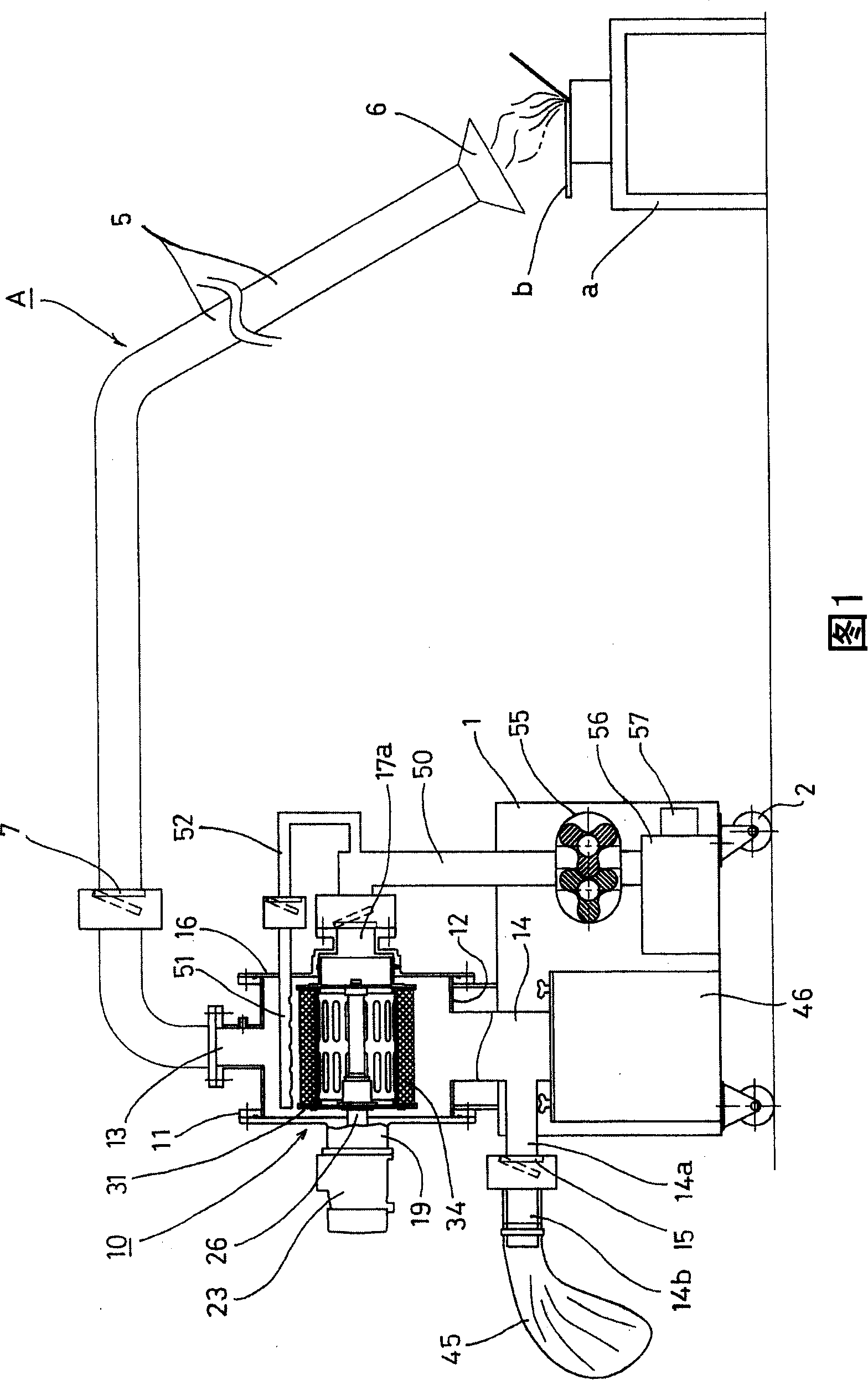

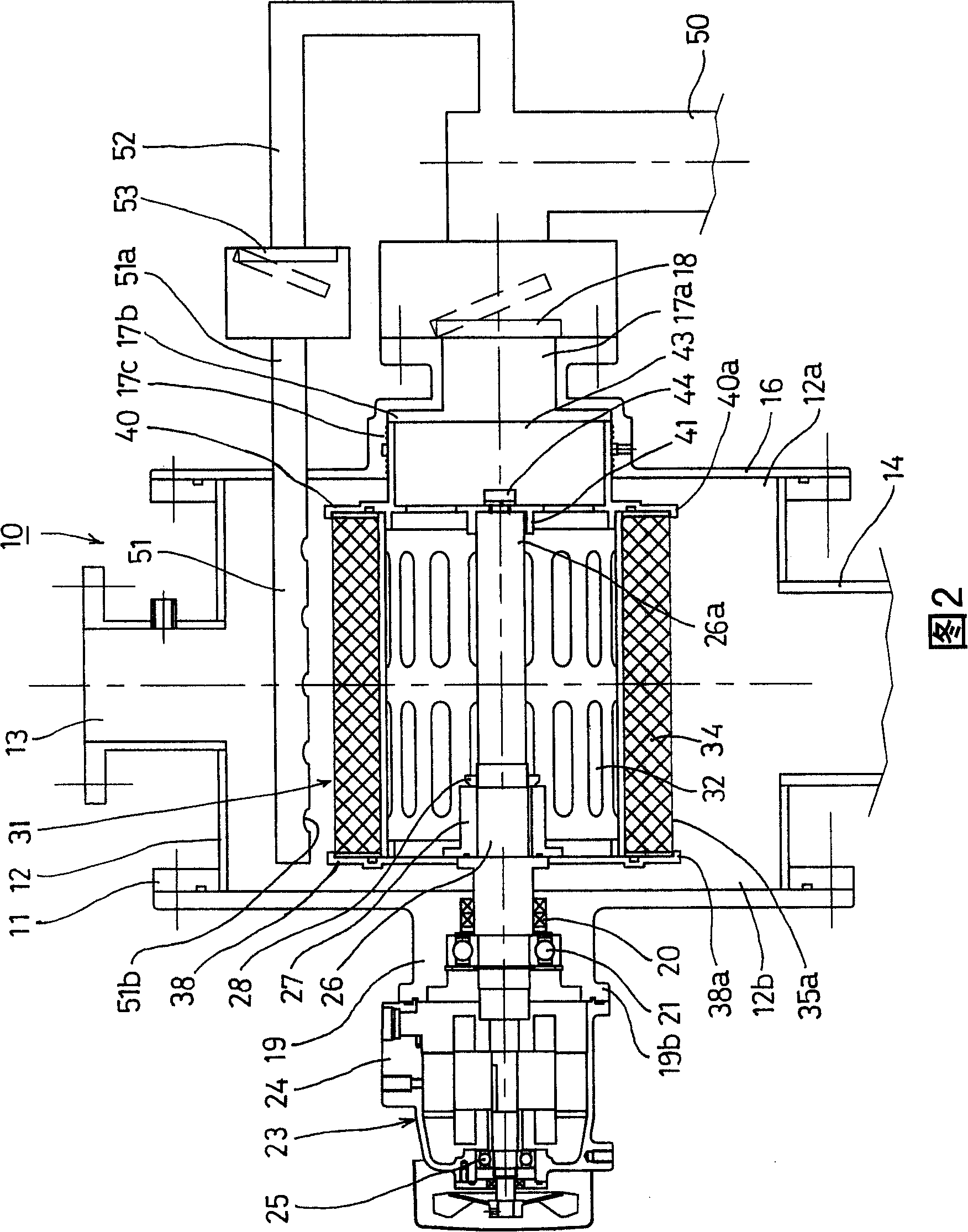

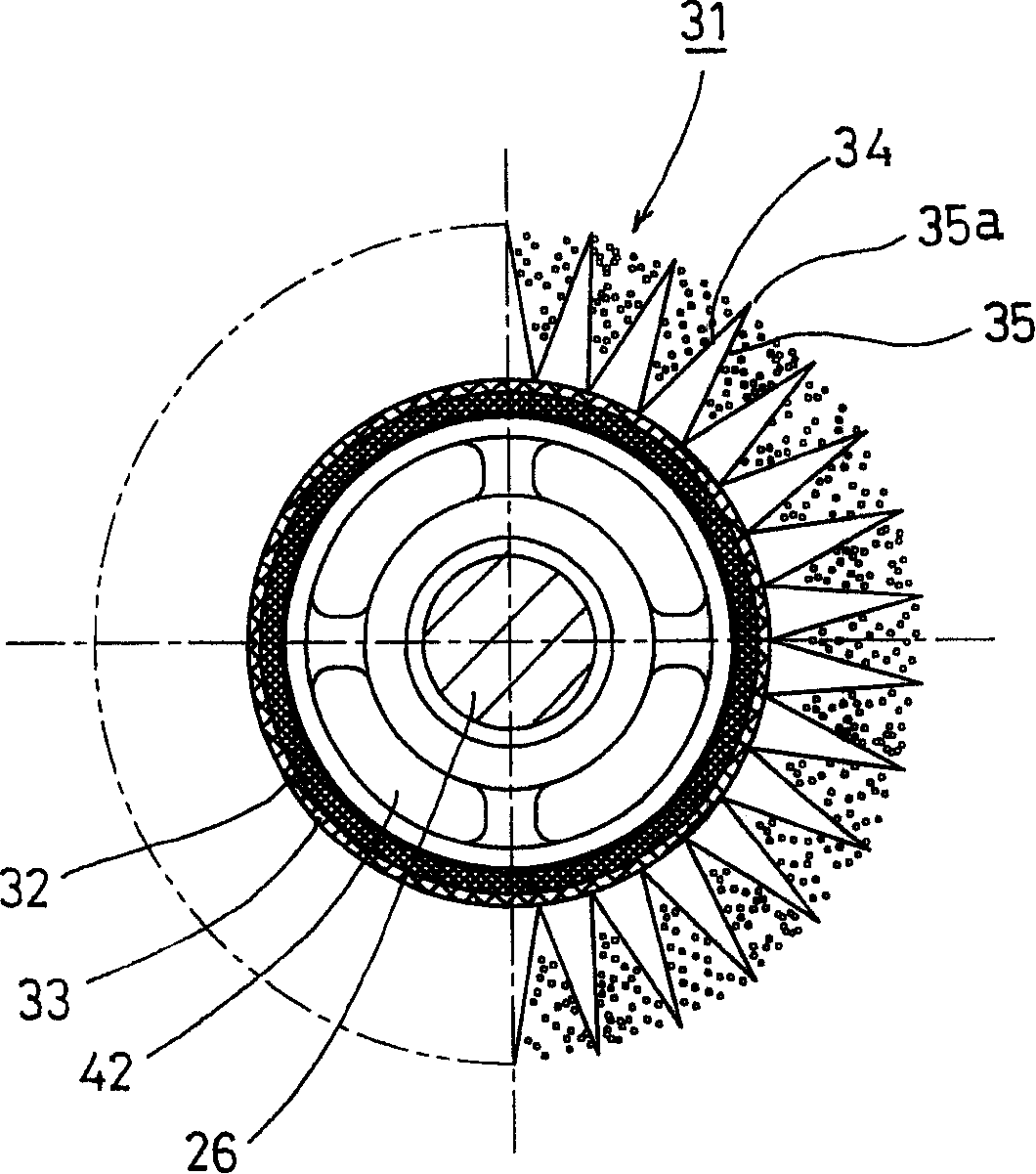

[0040] As shown in FIG. 1 , the dust collecting device A of the first embodiment is composed of a collection unit 10 and a Roots-type blower 55, and the collection unit 10 makes viscous dust generated by welding, dust generated by a grinding machine, etc. The mist and dust are sucked together with the surrounding air by the suction cover 6 arranged at the front end of the suction pipe 5 to collect the mist and dust. The Roots blower 55 makes the housing 11 of the collection unit 10 The air passing through the unit is discharged to the outside while the inside becomes negative pressure, and the collecting unit 10 and the Roots blower 55 are installed on a frame 1 having rollers 2 . 7 is a check valve installed on the suction pipe 5 .

[0041] The housing 11 of the trapping unit 10 is composed of a cylindrical housing main body 12 , an end cover 16 and a frame 19 . The end cap 16 is provided with an outflow port 17 a having a check valve 18 and is attached to the opening end 12...

no. 2 approach

[0085] FIG. 10 shows the dust collector B of the second embodiment. The main structure of the dust collector B is the same as that of the dust collector A of the above-mentioned first embodiment.

[0086] The dust collector B is composed of a collection unit 110 and a Roots-type blower 160. The collection unit 110 makes fine dust such as flour, plastic, paper, wood and other non-viscous light dust class together with the surrounding air by the air. The suction hood 106 arranged at the front end of the suction pipe 105 sucks and collects the dust; the Roots blower 160 turns the inside of the housing 111 of the collection unit 110 into a negative pressure, and makes the dust passing through the unit The air is exhausted to the outside, and the capturing unit 110 and the Roots blower 160 are provided on the vehicle frame 101 having the rolling wheels 102 . 107 is a check valve attached to the suction pipe 105 .

[0087] The housing 111 of the trapping unit 110 is composed of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com