Low resistance/high B-value negative temperature coefficient thermo-sensitive material and method for preparing same

A technology of negative temperature coefficient and heat-sensitive material, applied in the field of low resistivity/high B value negative temperature coefficient heat-sensitive material and its preparation, can solve the problem of difficulty in meeting this requirement, and achieve the effect of good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

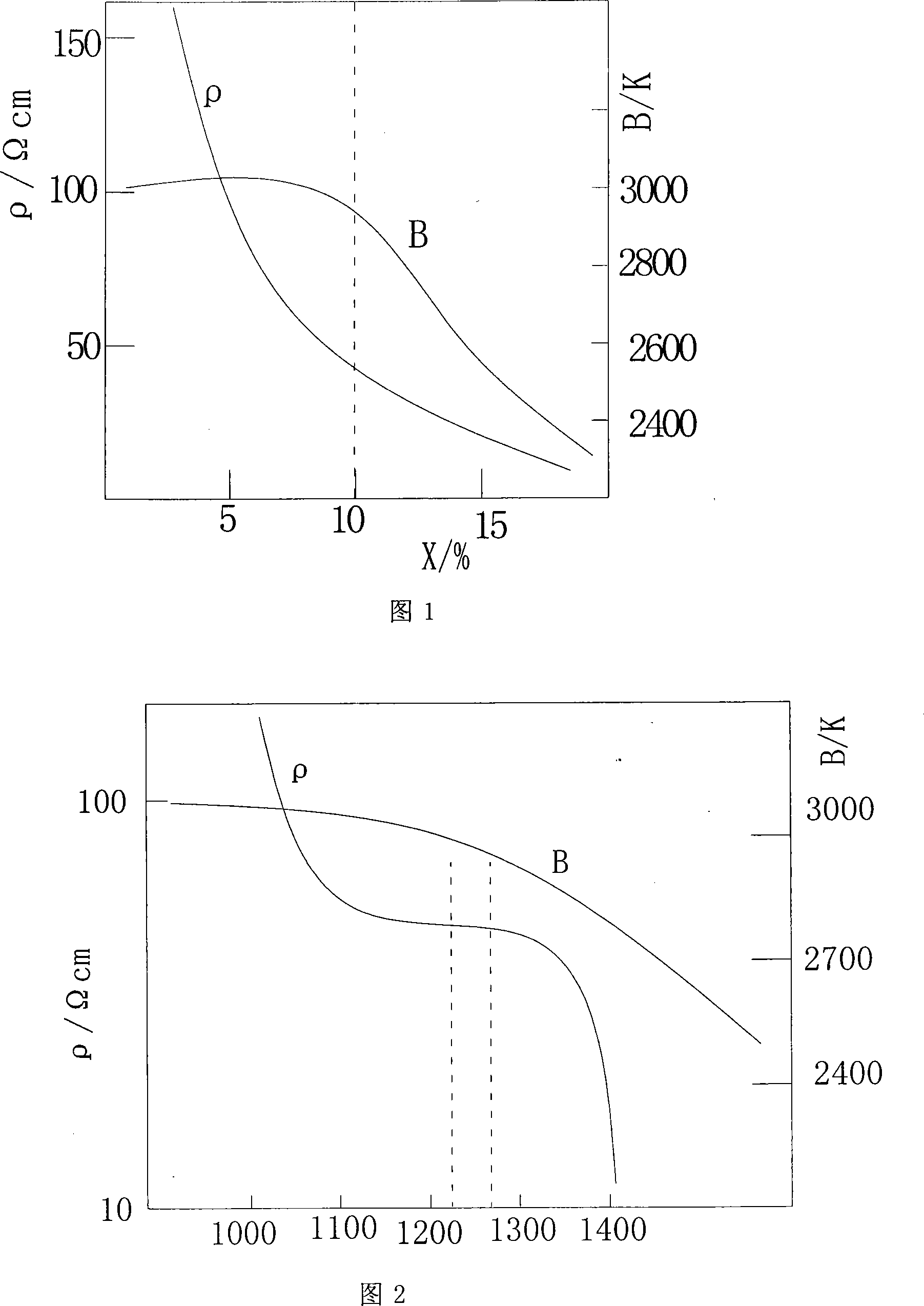

[0026] 1. Formula: take MnO2, TiO2 and CuO as raw materials, the purity is CP, take MnO2:TiO2:

[0027] CuO=65:15:20(%wt)+8% (additive)

[0028] =70:10:20(%wt)+8% (additive)

[0029] =72:8:20 (%wt)+8% (additive)

[0030] =73:5:20(%wt)+8% (additive)

[0031] Additives: ZnO: CaO: Nb2O5 = 30: 60: 10% wt, ball milled for 8 hours, pre-calcined at 750°C for 3 hours.

[0032] 2. Ball mill the above proportioned ingredients for 12 hours, material: water: ball = 1.0: 1.1: 1.5

[0033] 3. Granulation: Add 23% wt of PVA glue solution with a concentration of 10% to the powder, manually granulate, and pass through a 80-200 mesh sieve.

[0034] 4. Forming: Use 20mpa pressure to form a Ф10 (mm) × 2.0mm green sheet, and the pressing density is 3.6g / cm 3 .

[0035] 5. Put the formed blank into a ceramic bowl and sinter at a high temperature of 1220° C. for 2.5 hours. The sintering curve is 13 hours at 25°-1220°...

Embodiment 2

[0042] The main formula is MnO2: TiO2: CuO=70:10:20%wt, the amount of additives is respectively taken as 5.0, 7.0, 8.0, 9.0, 10.0, 12.0%wt, and the sample of Ф10 is made by the technique of embodiment 1, and its The test results are shown in the table below (based on 100 chips)

[0043] MnO2

[0044] The results show that with the increase of the additive amount, the resistance value decreases, and the B value also decreases obviously. When the amount of additives reaches 12%, the resistance is 5Ω, the B value is only 2280K, and the dispersion of the material becomes larger.

Embodiment 3

[0046] The formula is MnO2: TiO2: CuO=70:10:20%wt, the amount of additives is 8%wt [according to the process of Example 1] to make Ф10 blanks, and sintering at different sintering temperatures. The measurement results of the samples are shown in the following table (Based on 100 chips)

[0047] Sintering temperature

(T / ℃)

MnO2

(%wt)

TiO2

(%wt)

CuO

(%wt)

Additives

(%wt)

ρ25 / Ωcm

B 25 / 50 / k

1160

1180

1200

1220

1240

1260

1280

70

70

70

70

70

70

70

10

10

10

10

10

10

10

20

20

20

20

20

20

20

8

8

8

8

8

8

8

534.8±18%

116.4±8%

55.6±5%

54.8±3%

38.4±7%

18.6±21%

10.4±34%

2874±3.6%

2810±1.0%

2770±0.4%

2740±0.6%

2700±1.2% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com