Oil-water well oil layer positioning deep penetration horizontal drilling device

A horizontal drilling and deep penetration technology, applied in drilling equipment, directional drilling, earthwork drilling, etc., can solve problems such as damaged casing, formation of compaction zone, complex equipment structure, etc. The effect of flow ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

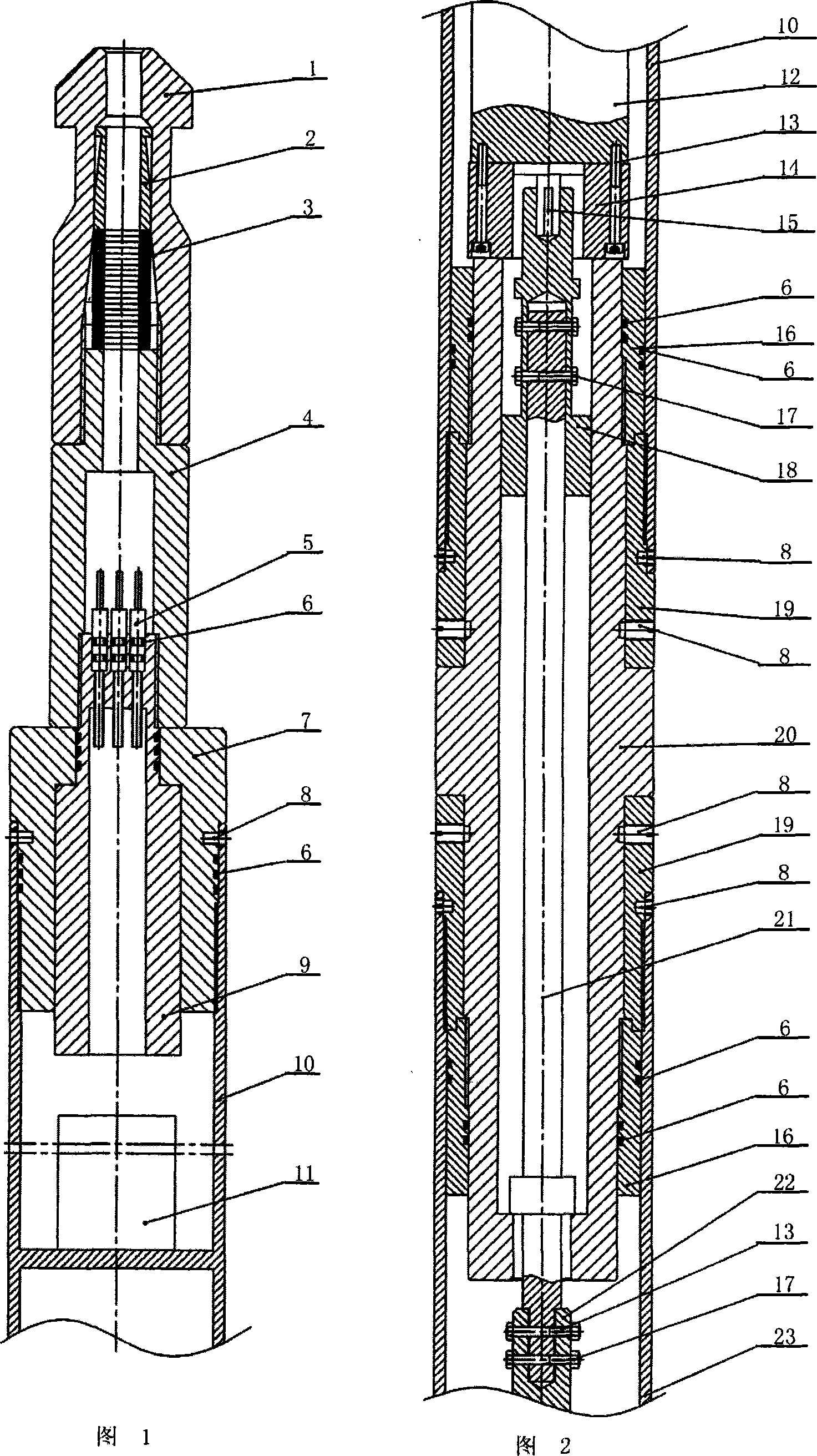

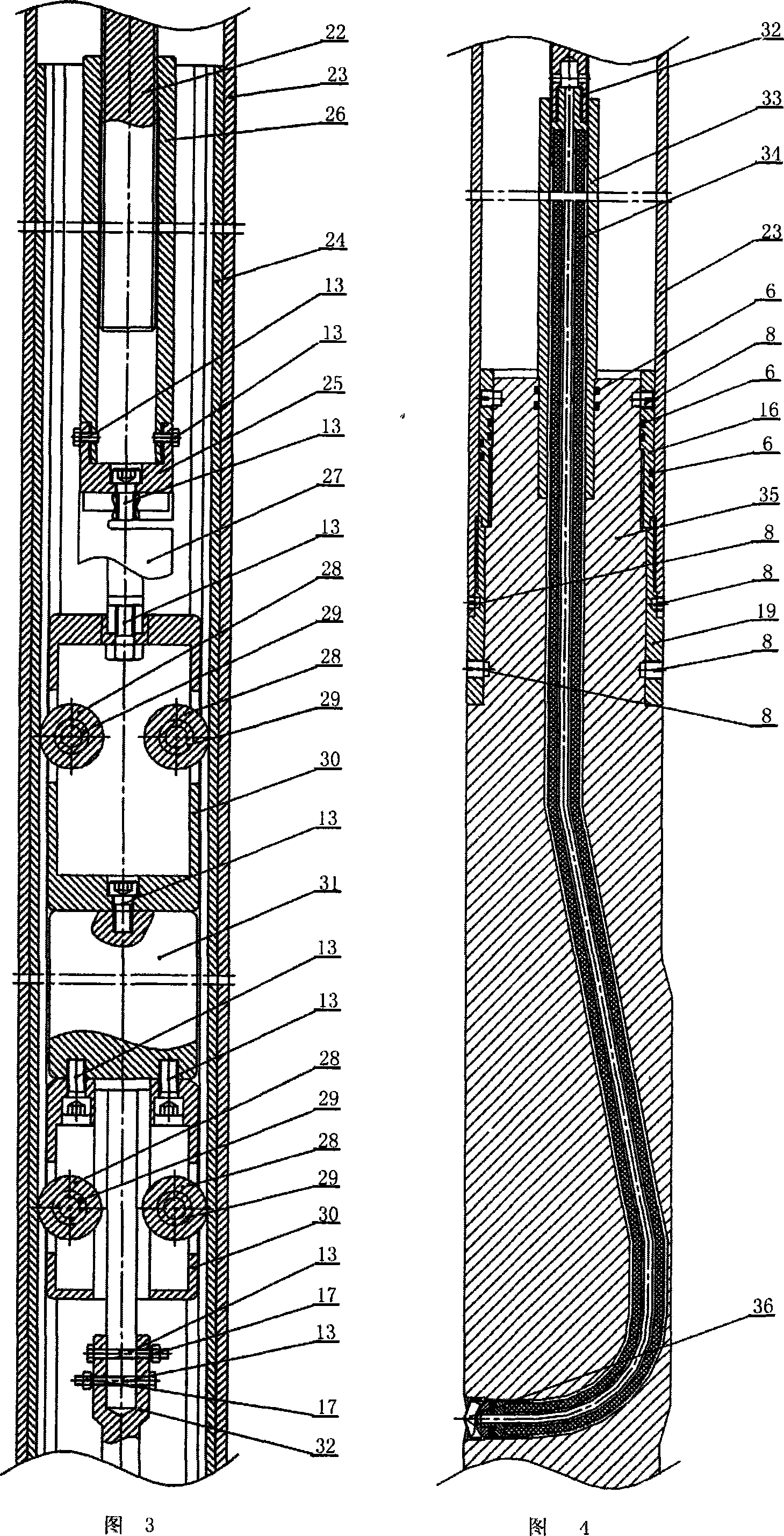

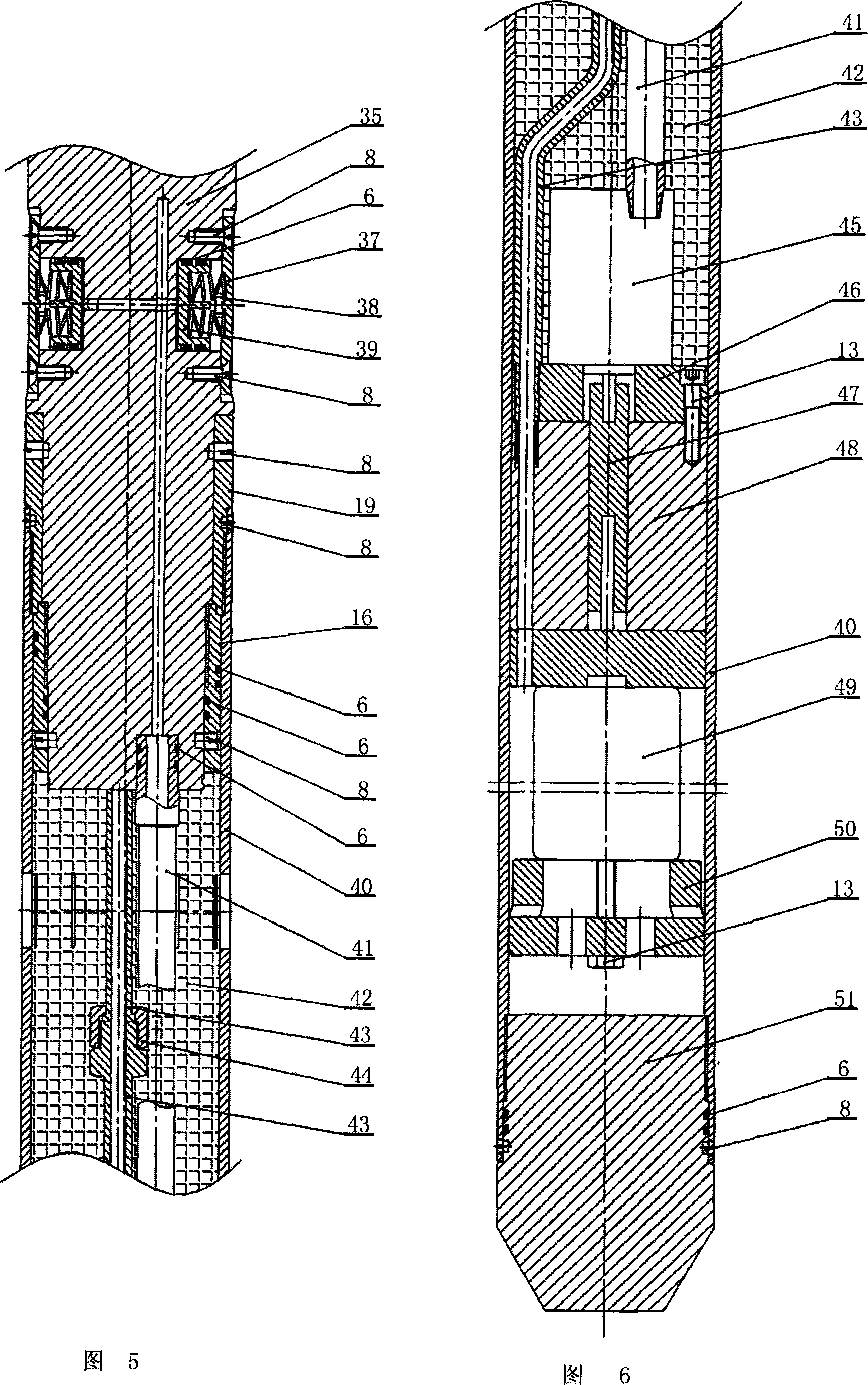

[0022] As shown in Figures 1 to 6, the fixed-point deep penetration horizontal drilling device for oil and water wells consists of a measurement and control system I, a stepping system II, a power system III, a drilling gun system IV, an anchoring system V and a circulation system VI.

[0023] a. As shown in Figure 1, the measurement and control system I consists of an upper connector 1, a cable connector 2, a gasket 3, a cable head pressure cap 4, a terminal post 5, an "O"-shaped sealing ring 6, a connecting body 7, and an anti-rotation pin 8 , terminal block 9, jacket 10 and embedded measurement and control device 11, wherein the upper joint 1 and the cable head pressure cap 4 are threadedly connected, the cable joint 2 and the gasket 3 are set in the upper joint 1, and are passed through the cable head pressure cap 4 Positioning and pressing, the cable head pressure cap ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap