Engine cylinder block lubricant oil path

A technology for engine cylinders and lubricating oil passages, which is applied in the directions of engine lubrication, engine components, and engine cooling. Simplified processing and optimal cooling and lubrication effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

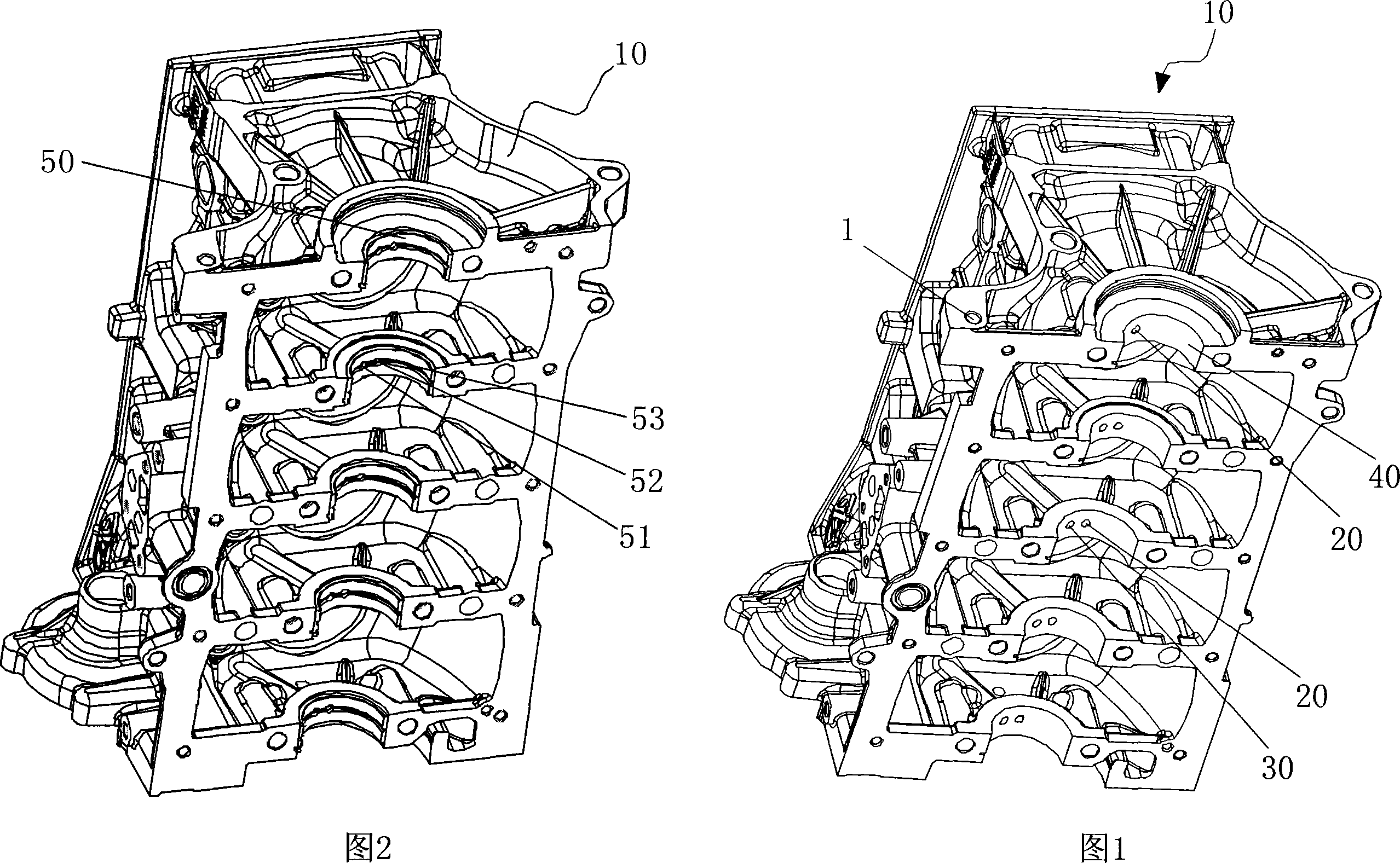

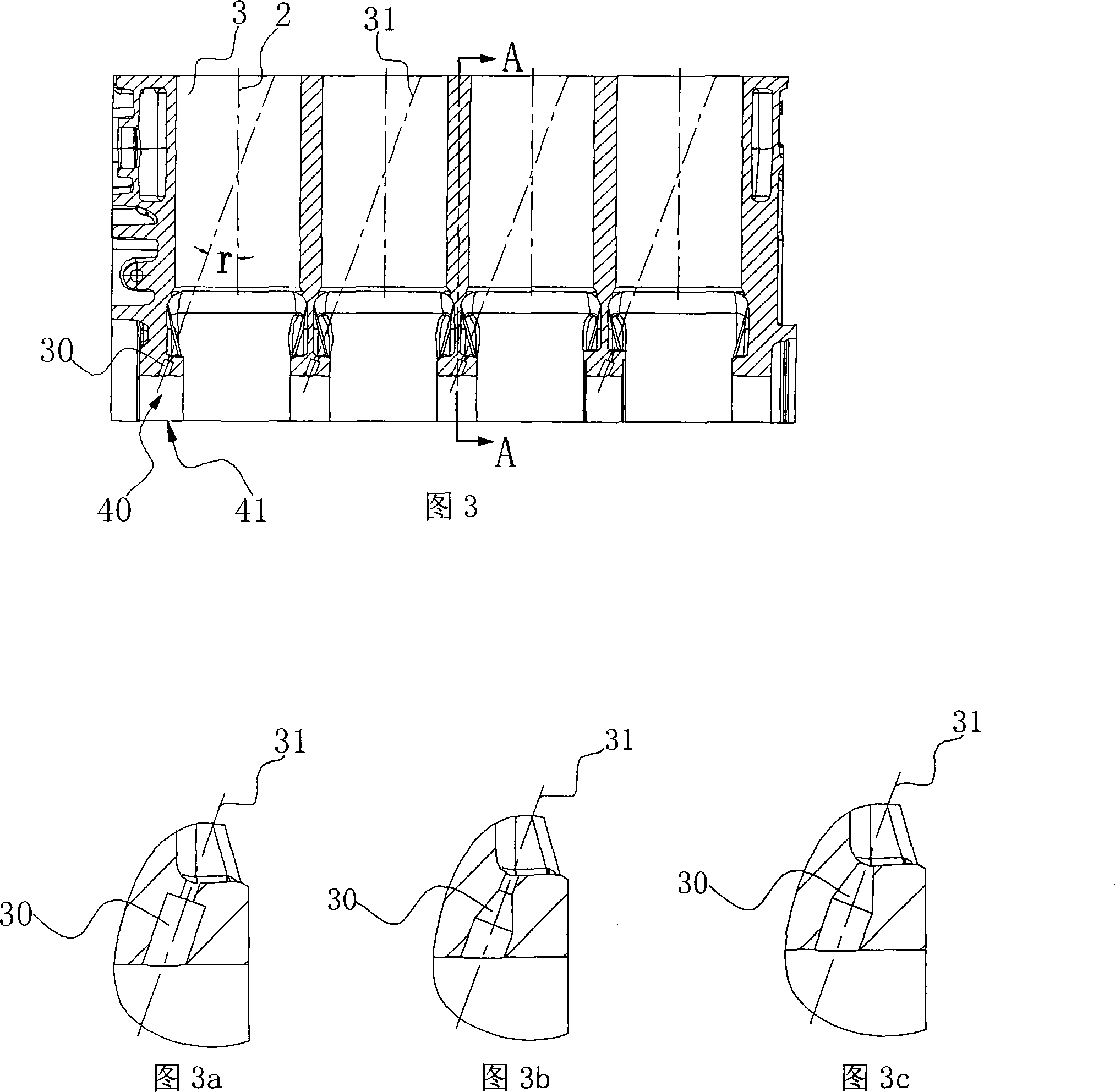

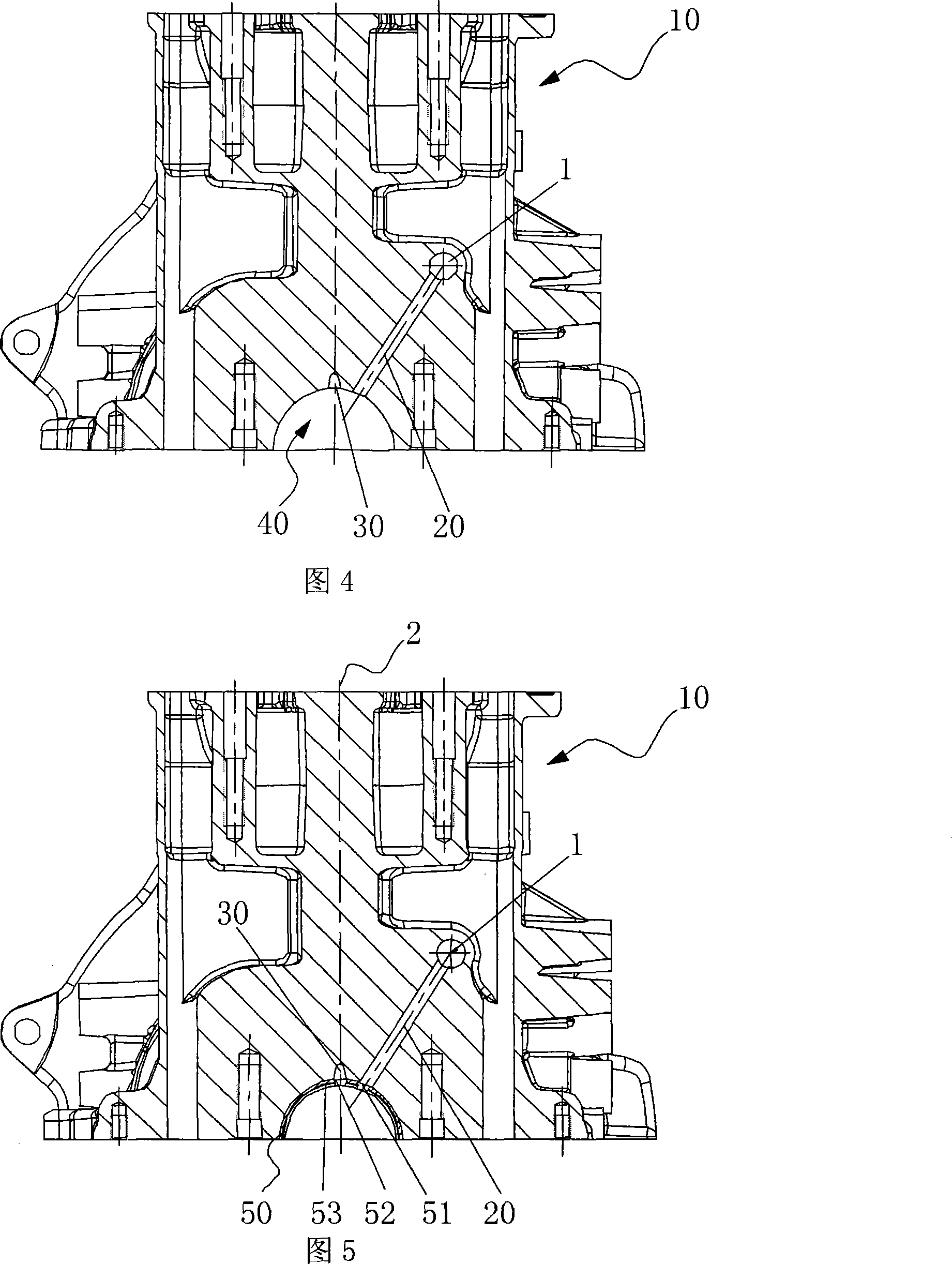

[0013] Figure 1 shows an isometric view of the cylinder block 10. The high-pressure oil pumped by the oil pump first enters the oil passage 4 through the oil passages of other parts, then enters the oil passage 5, enters the oil passage 6 through the oil filter, and then enters The main oil passage 1 penetrates the front and rear ends of the engine. The main oil passage 1 respectively introduces oil into the main bearing lubricating passage 20. The main bearing lubricating passage 20 communicates with the main bearing hole 40, that is, the main bearing lubricating passage 20 extends to the main bearing hole 40 In the hole wall of the main bearing, the main bearing hole 40 on the side of the main bearing lubricating channel 20 is provided with a throttle hole 30, and the main bearing hole 40 is provided with a first hole 51 and a second hole 51 on the wall of the main bearing shell 50. The hole 52 and the oil groove 53 connecting the first hole 51 and the second hole 52, that is, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com