Pendulum impact machine low-temperature automatic material feeding centring device and method thereof

An impact testing machine and automatic feeding technology, which is applied in impact testing, measuring devices, manipulators, etc., can solve problems such as difficult to guarantee the time limit, high labor intensity, frostbite fingers, etc., to save labor costs, improve work efficiency, The effect of avoiding frostbite fingers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

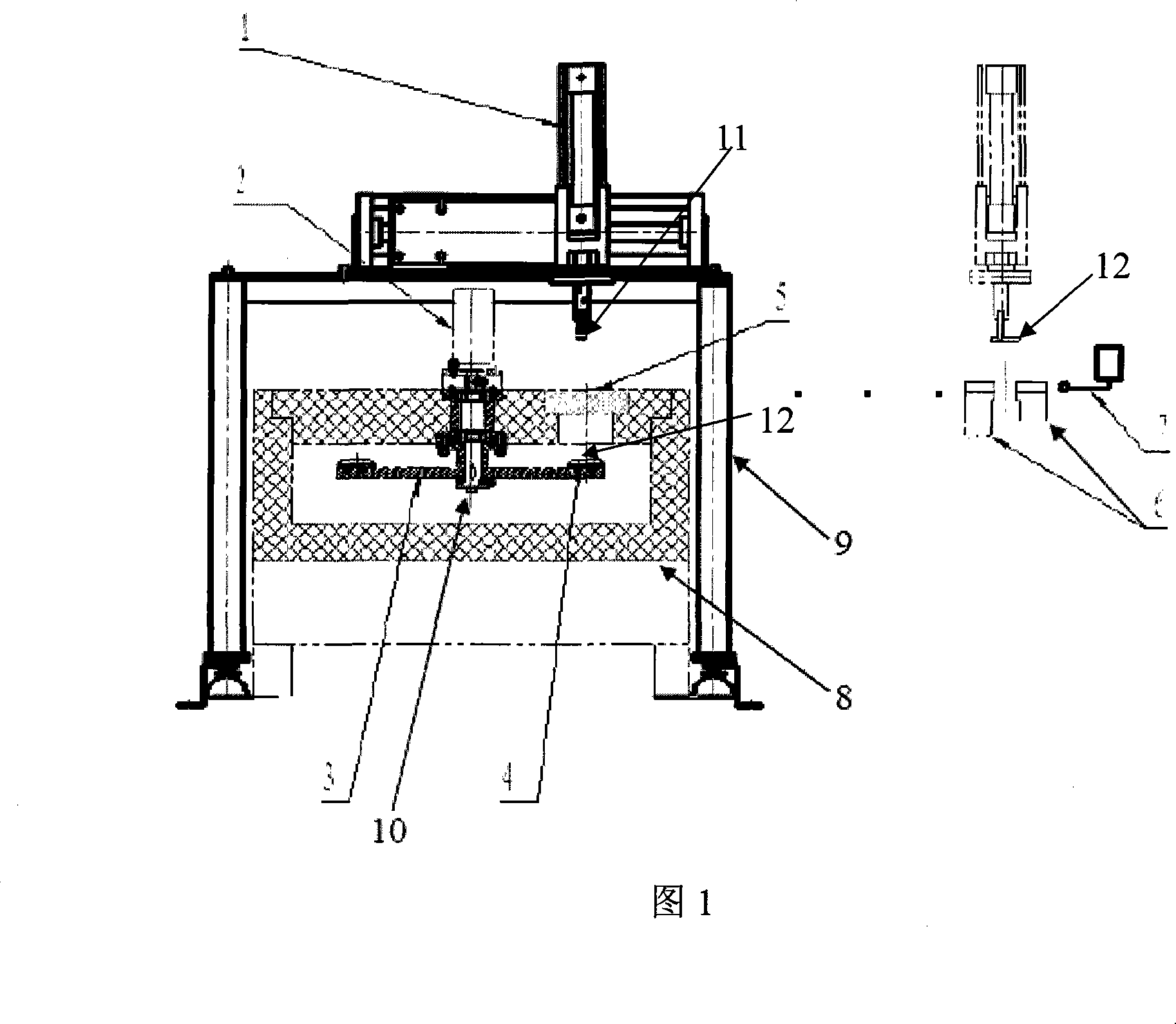

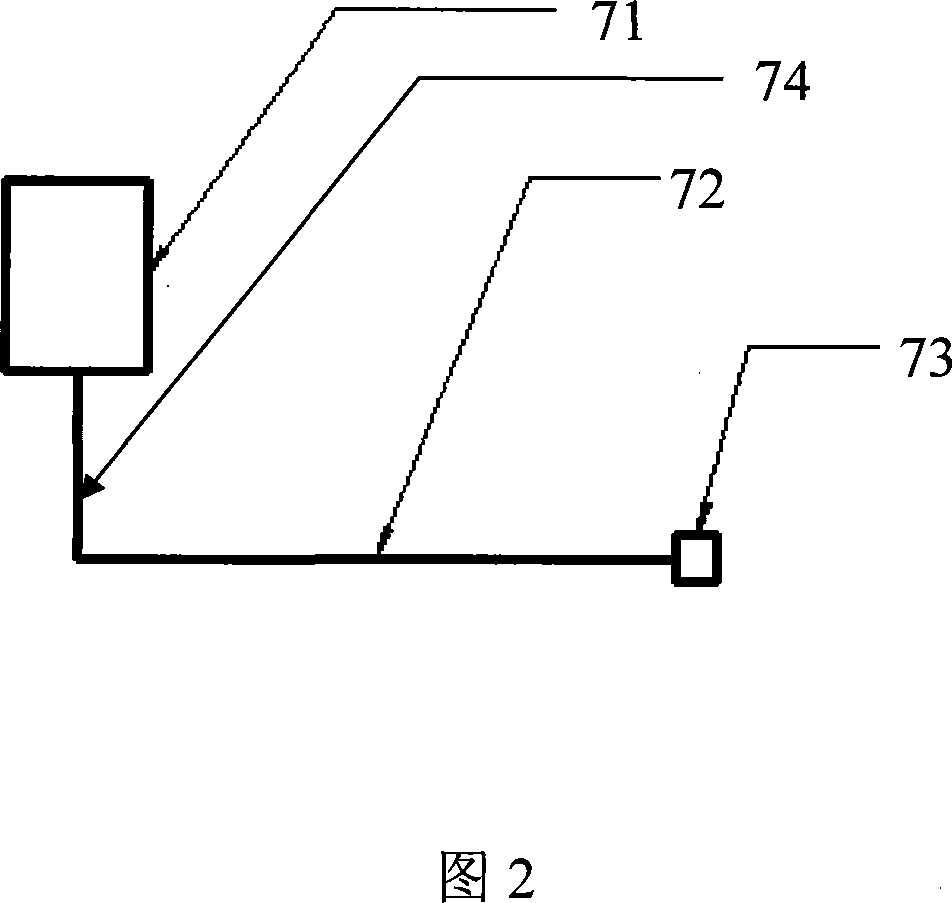

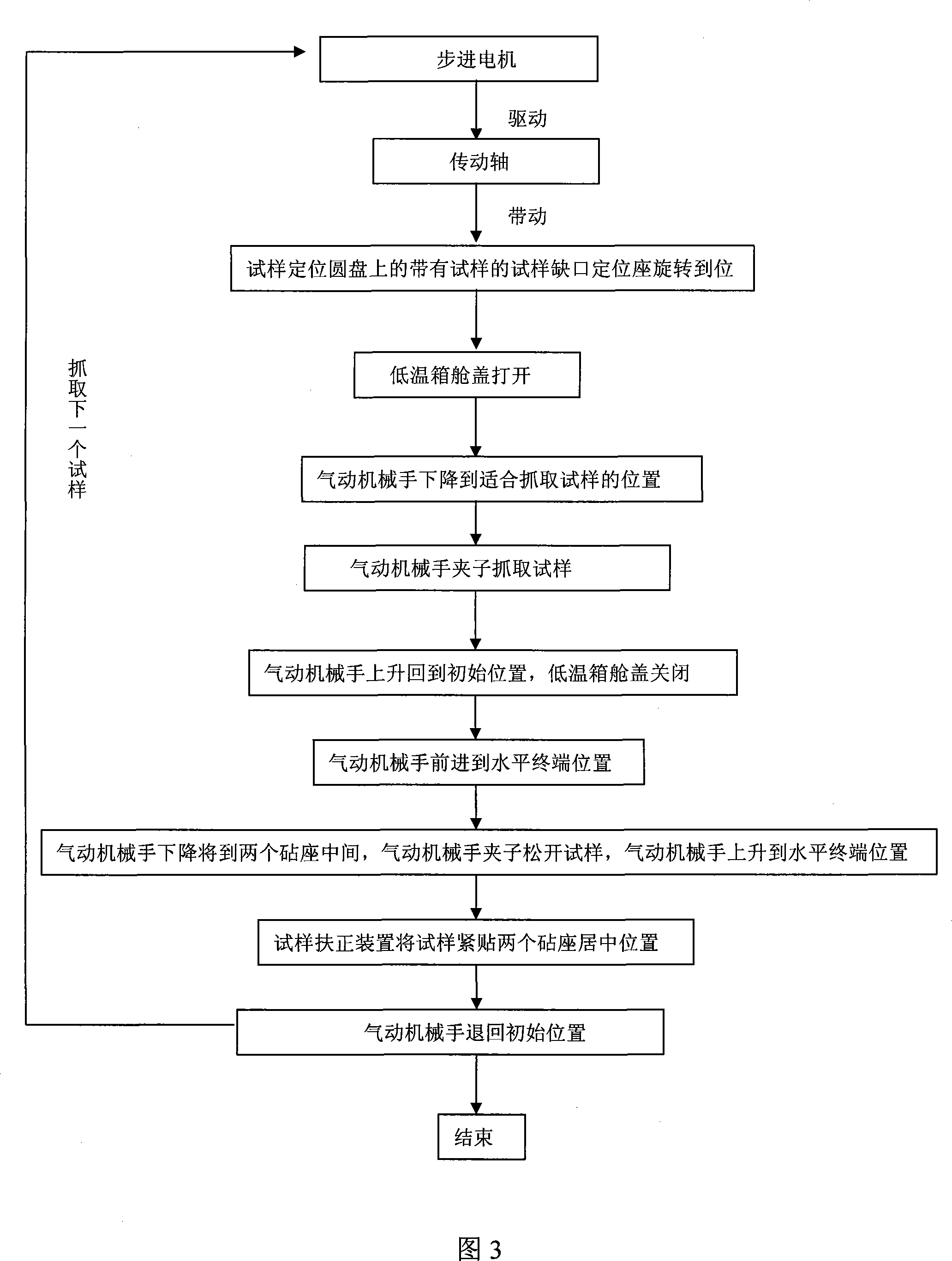

[0050] A low-temperature automatic feeding and centering device for a pendulum impact testing machine, which includes a pneumatic manipulator 1, a stepping motor 2, an anvil 6, a low-temperature box 8, a manipulator bracket 9, a transmission shaft 10, and an external electrical program control system (Fig. Not shown in), the sample 12 is characterized in that: it also includes a sample positioning disc 3, a sample notch positioning seat 4, a low temperature box hatch 5, and a sample righting device 7;

[0051] The external electrical program control system is respectively connected to the pneumatic manipulator 1, the stepping motor 2, the hatch cover 5 of the cryogenic box, and the sample righting device 7 through the electrical control bus;

[0052] The hatch 5 of the cryogenic box is arranged on the top of the cryogenic box 8, and its position corresponds to the position where the pneumatic manipulator 1 descends and enters the cryogenic box;

[0053] The sample positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com