Mounting frame for solar cell module

A technology for solar cells and mounting brackets, which is applied in the field of solar cells and can solve problems such as inability to adjust, low output power, and fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

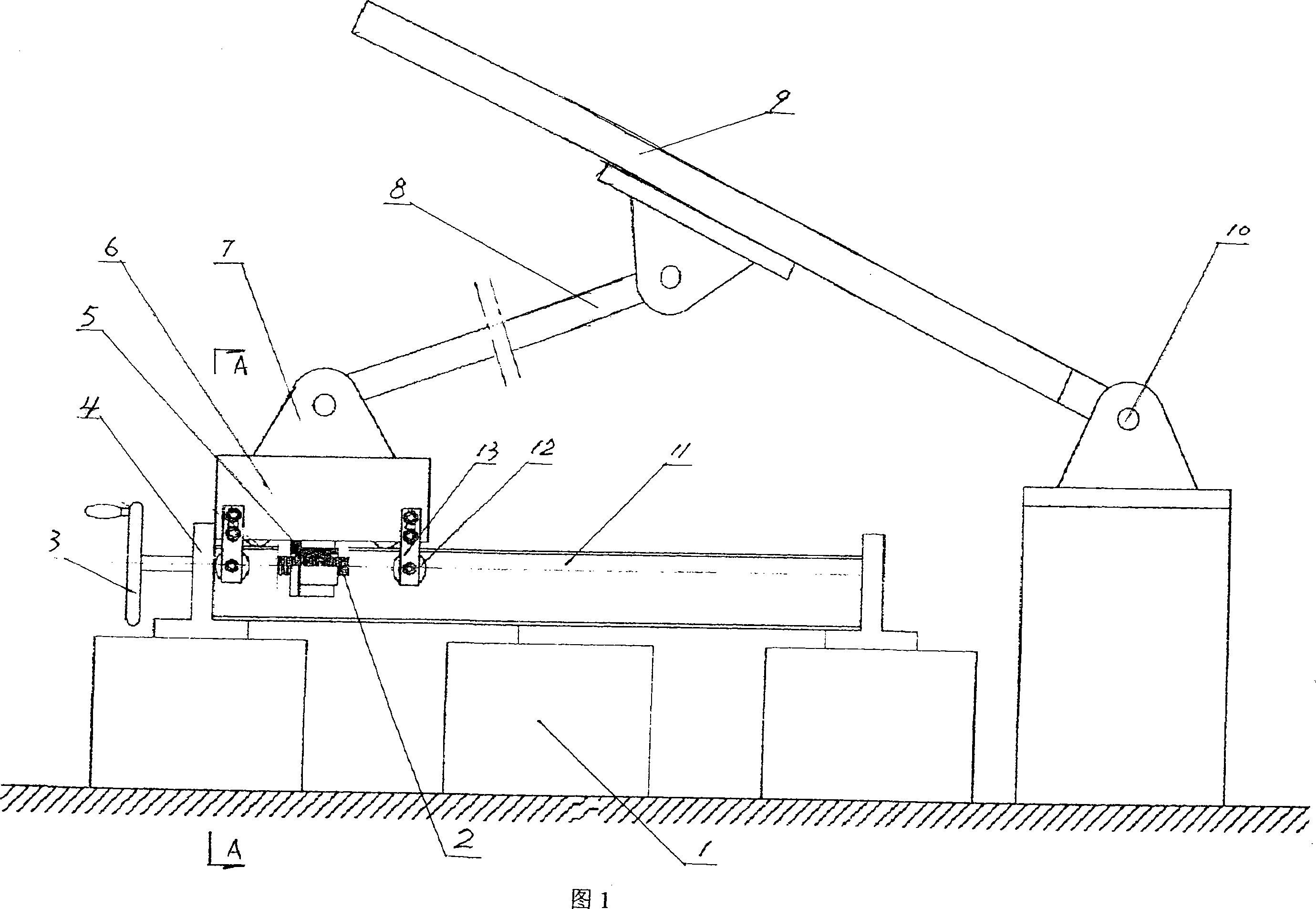

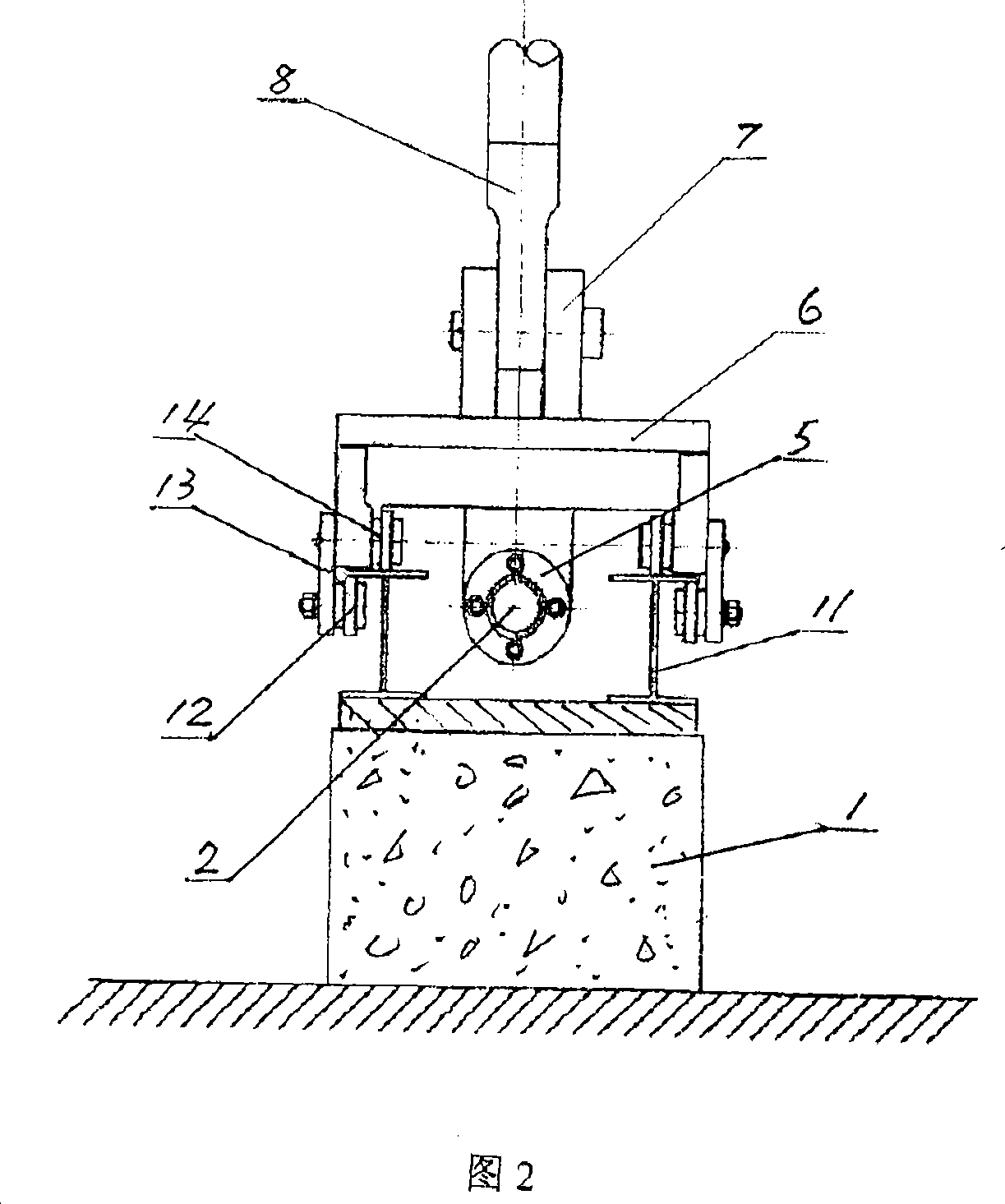

[0012] As shown in FIGS. 1 and 2 , the solar cell module mounting bracket of the present invention includes a base and a solar cell module 9 . Two guide rails 11 are fixed on the base, and the two guide rails are parallel, and bearings 4 are fixed on the base between their same ends. Said support 4 contains a vertical plate, and the horizontal plate formed with it is arranged on the lower side of the vertical plate. The vertical plate surface wherein is perpendicular to the longitudinal direction of guide rail 11, is all processed with through hole on it, and the through hole on two support 4 vertical plates is corresponding. The cross-sections of the two guide rails 11 are I-shaped, and the two side plates of the slide seat 6 are all convex downwards, and an upper roller 14 is installed on the inside of the raised part of the two side plates by means of pin shafts and bearings, and the four upper rollers Arranged symmetrically in a quadrangular shape, they are placed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com