A hot melt binding clamp

A binding clip and hot-melt technology, applied in binding, book binding, adhesives for binding, etc., can solve the problem of difficult page turning, and achieve the effect of easy turning and firm binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

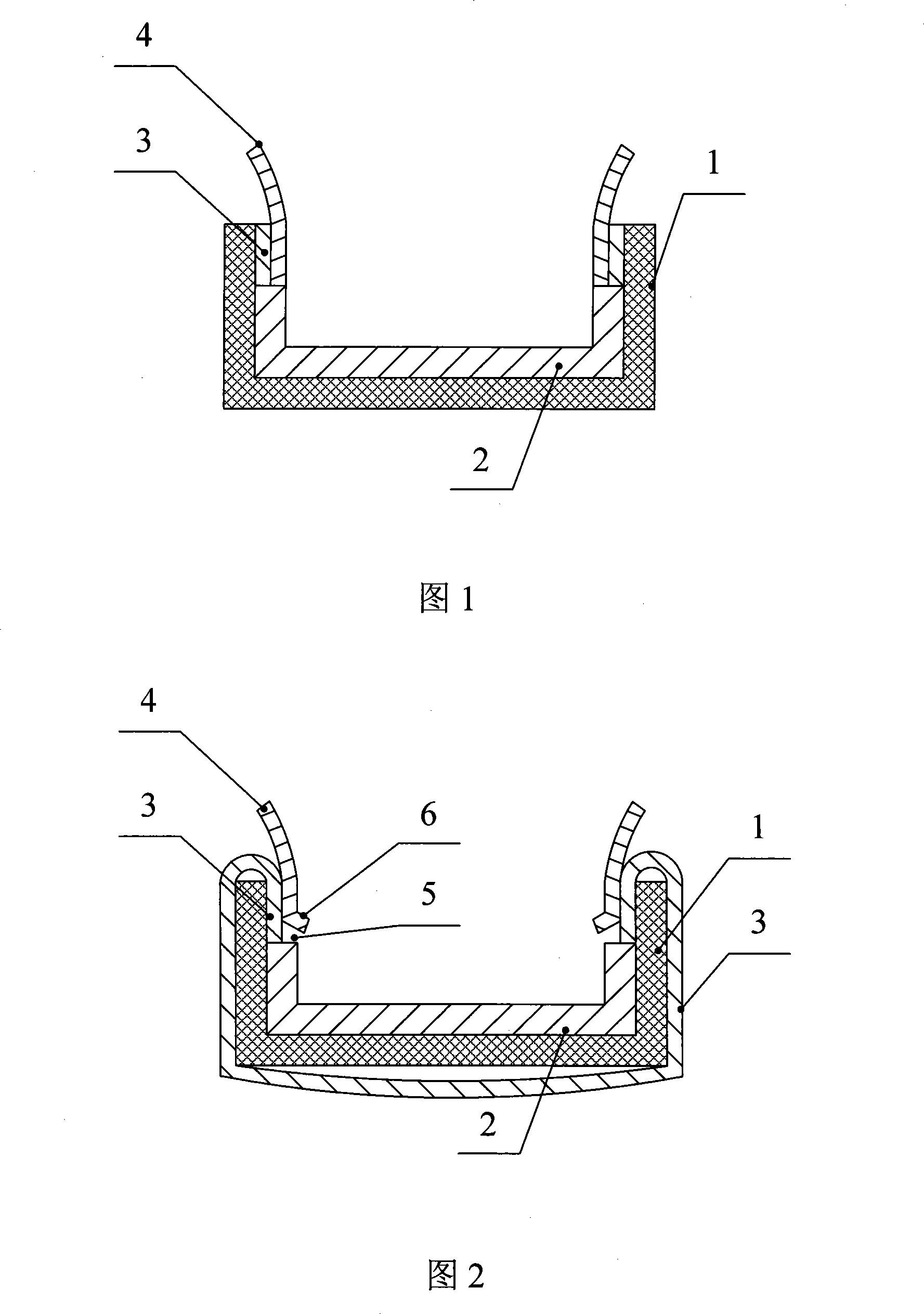

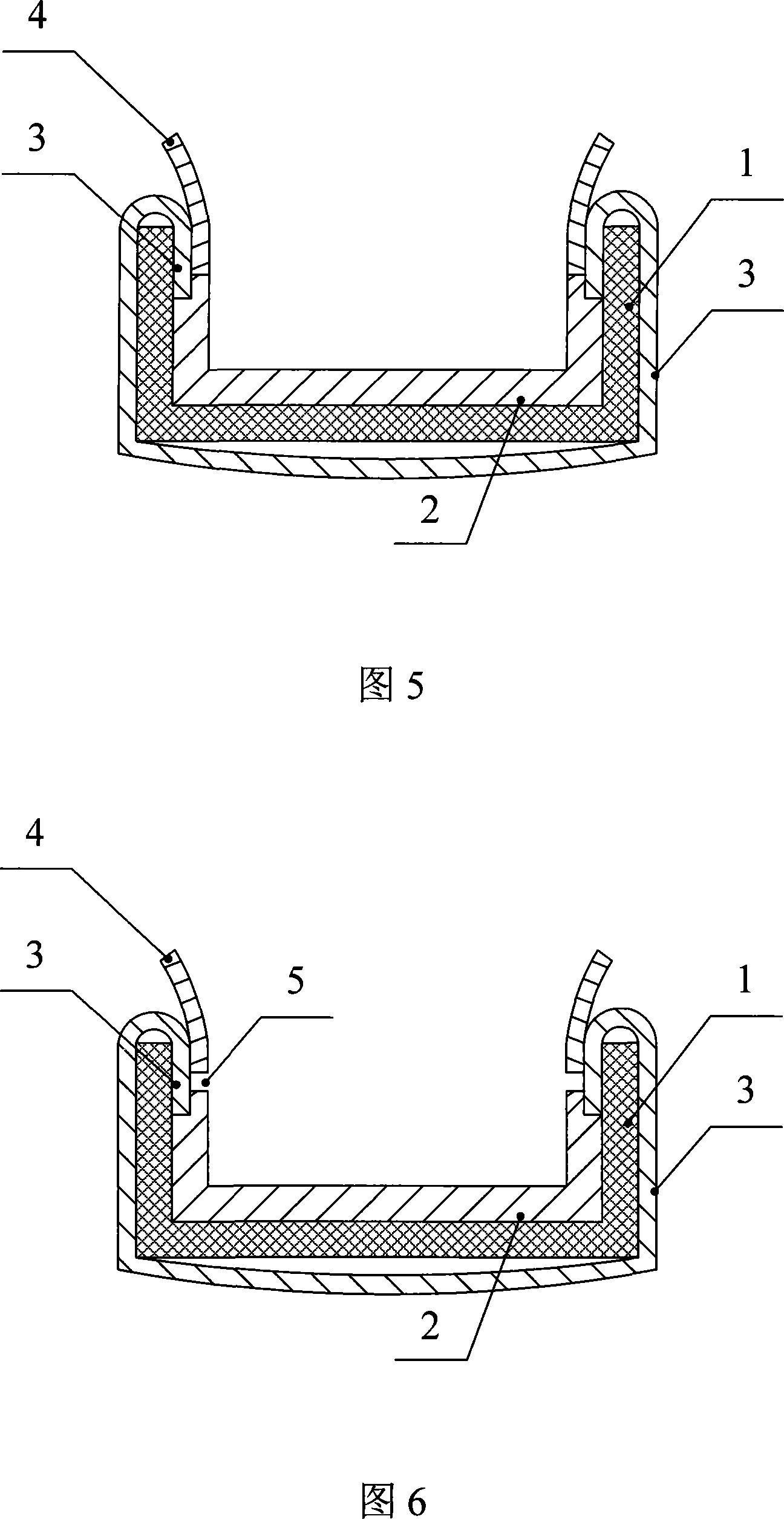

[0029] As shown in Figure 1, a hot-melt binding clip includes a U-shaped groove 1, a U-shaped hot-melt adhesive 2 is provided at the bottom of the U-shaped groove 1, and the two ends of the inner wall of the U-shaped groove 1 are located at U-shaped A thickened layer 3 is arranged on the upper side of the hot melt adhesive 2 , and an active layer 4 is arranged inside the thickened layer 3 . The thickened layer 3 and the active layer 4 are in contact with the sides of the U-shaped hot melt adhesive 2 . The sum of the thicknesses of the thickened layer and the active layer is equal to the thickness of the sides of the U-shaped hot melt adhesive, and the end of the active layer outside the U-shaped groove is connected as a cover or back cover material.

Embodiment 2

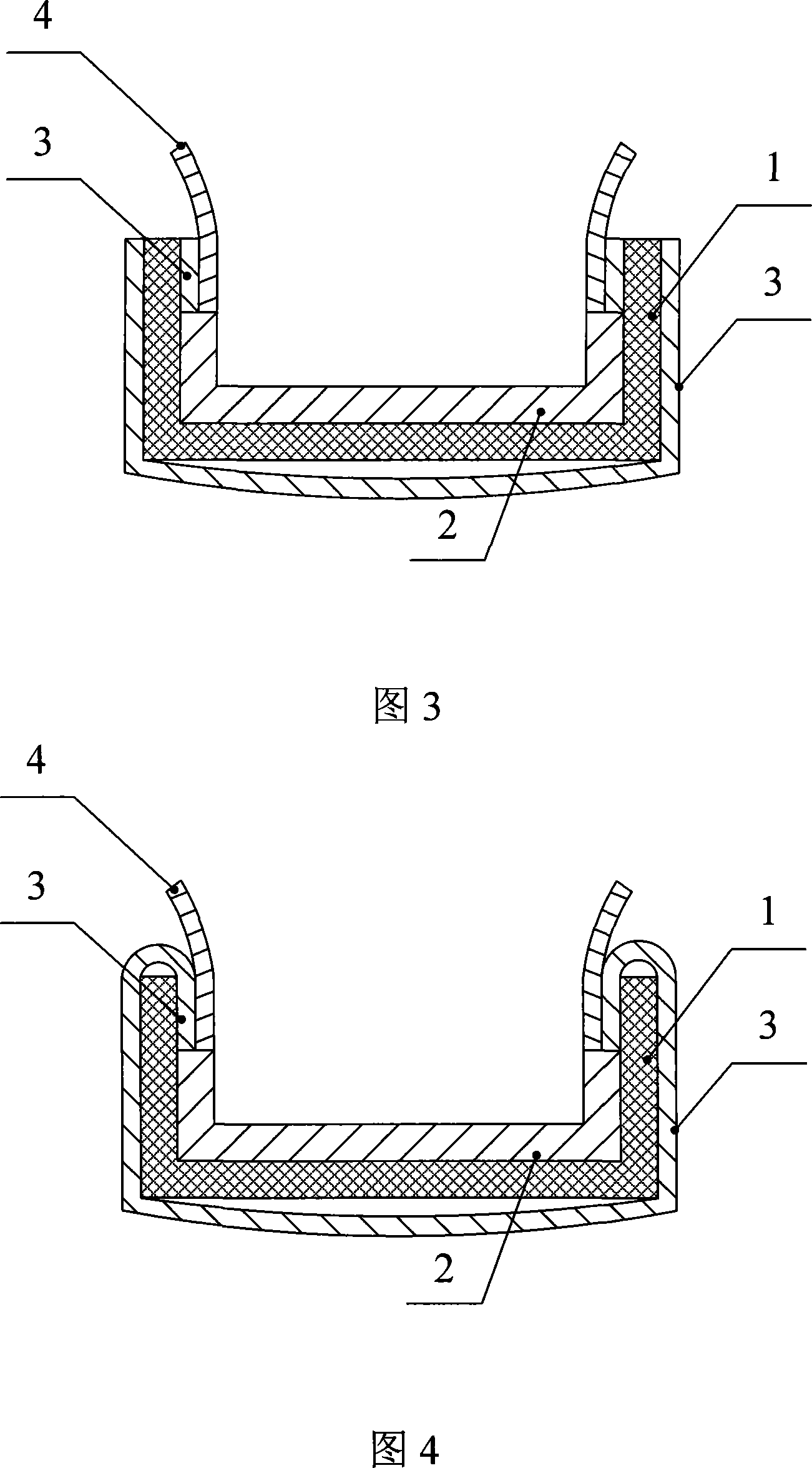

[0031] As shown in Figure 2, a hot-melt binding clip includes a U-shaped groove 1, a U-shaped hot-melt adhesive 2 is provided at the bottom of the U-shaped groove 1, and the two ends of the inner wall of the U-shaped groove 1 are located at U-shaped A thickened layer 3 is arranged on the upper side of the hot melt adhesive 2 , and an active layer 4 is arranged inside the thickened layer 3 . The thickened layer 3 is in contact with the upper side of the U-shaped hot melt adhesive 2, and the end 6 of the active layer located in the U-shaped groove is not in contact with the upper side of the U-shaped hot melt adhesive and forms a gap 5 , the end 6 tilts toward the U-shaped groove. The outside of the U-shaped groove 1 is also provided with a thickened layer 3, the thickened layer 3 on the outside of the U-shaped groove 1 is connected with the thickened layer 3 on the inside of the U-shaped groove 1, and the thickened layer 3 can be As a cover for hot-melt binders. The material ...

Embodiment 3

[0033] As shown in Figure 3, a hot-melt binding clip includes a U-shaped groove 1, a U-shaped hot-melt adhesive 2 is provided at the bottom of the U-shaped groove 1, and the two ends of the inner wall of the U-shaped groove 1 are located at U-shaped A thickened layer 3 is arranged on the upper side of the hot melt adhesive 2 , and an active layer 4 is arranged inside the thickened layer 3 . The thickened layer 3 and the active layer 4 are in contact with the upper side of the U-shaped hot melt adhesive 2 . The outer side of the U-shaped groove 1 is also provided with a thickened layer 3, and the thickened layer 3 can be used as the outer skin of the hot-melt binder. The sum of the thicknesses of the thickened layer and the active layer is equal to the thickness of the side of the U-shaped hot melt adhesive, and the end of the active layer outside the U-shaped groove is connected as a cover or back cover material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com