Environment-friendly type azeotropic coolant adaptated for single-stage compression refrigeration system

A refrigeration system, single-stage compression technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve problems such as the inability to guarantee the azeotropic properties of R134a+R600a mixtures, the actual concentration deviation, and the large difference in solubility, and achieve good results. The effect of mutual solubility, increased evaporation pressure, and increased cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

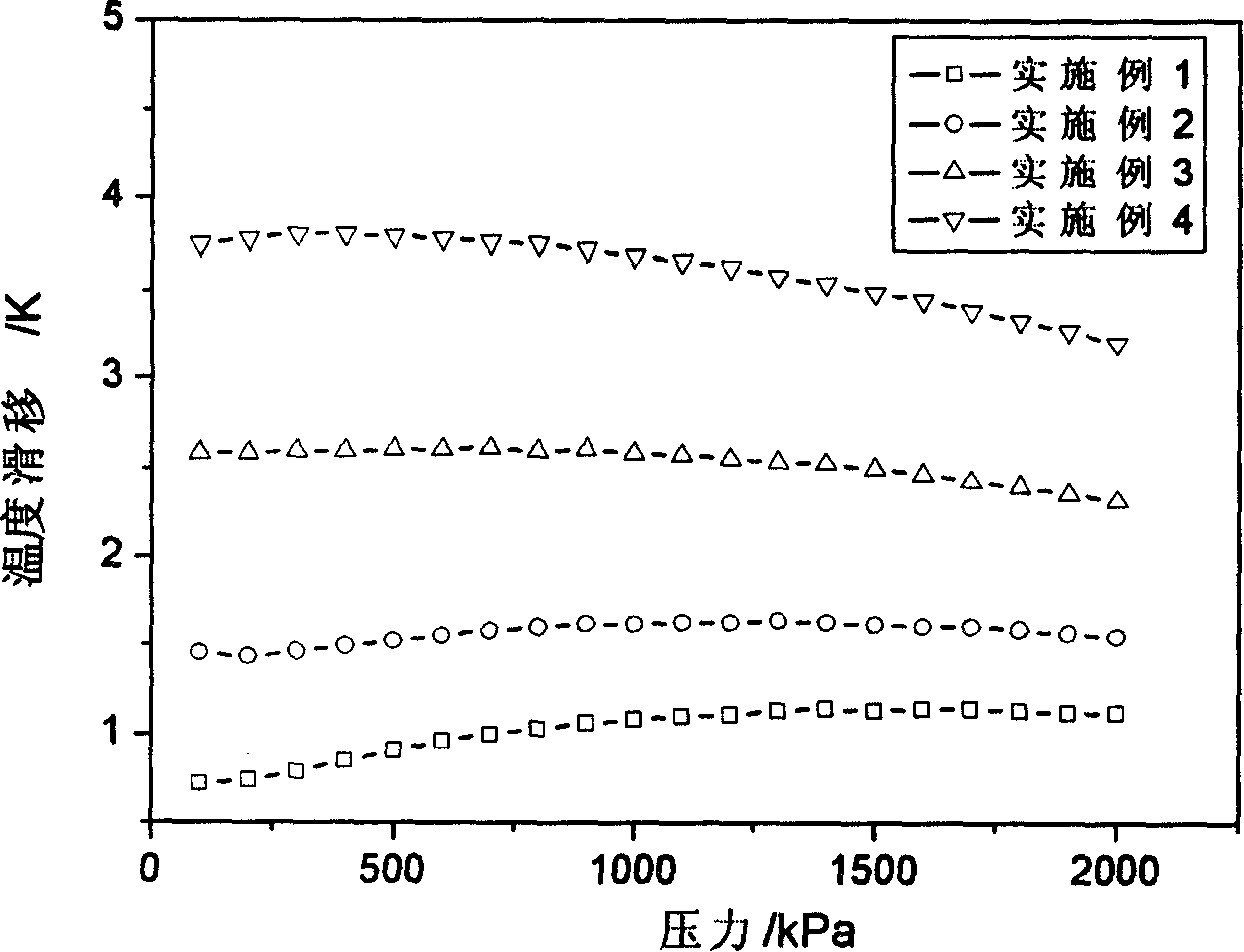

Embodiment 1

[0021] Example 1: 1,1,1,2-tetrafluoroethane with a molar concentration of 63% and isobutane with a molar concentration of 37% are physically mixed at room temperature to obtain a single-stage compression refrigeration system. mixed refrigerant.

Embodiment 2

[0022] Example 2: 1,1,1,2-tetrafluoroethane with a molar concentration of 61% and isobutane with a molar concentration of 39% are physically mixed at room temperature to obtain a single-stage compression refrigeration system mixed refrigerant.

Embodiment 3

[0023] Example 3: 1,1,1,2-tetrafluoroethane with a molar concentration of 60% and isobutane with a molar concentration of 40% are physically mixed at room temperature to obtain a single-stage compression refrigeration system mixed refrigerant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com