De-airing hydraulic tensioner

A hydraulic tensioner and degassing technology, which is applied to belts/chains/gears, mechanical equipment, transmissions, etc., can solve problems such as rattling, and achieve the effect of suppressing rattling noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

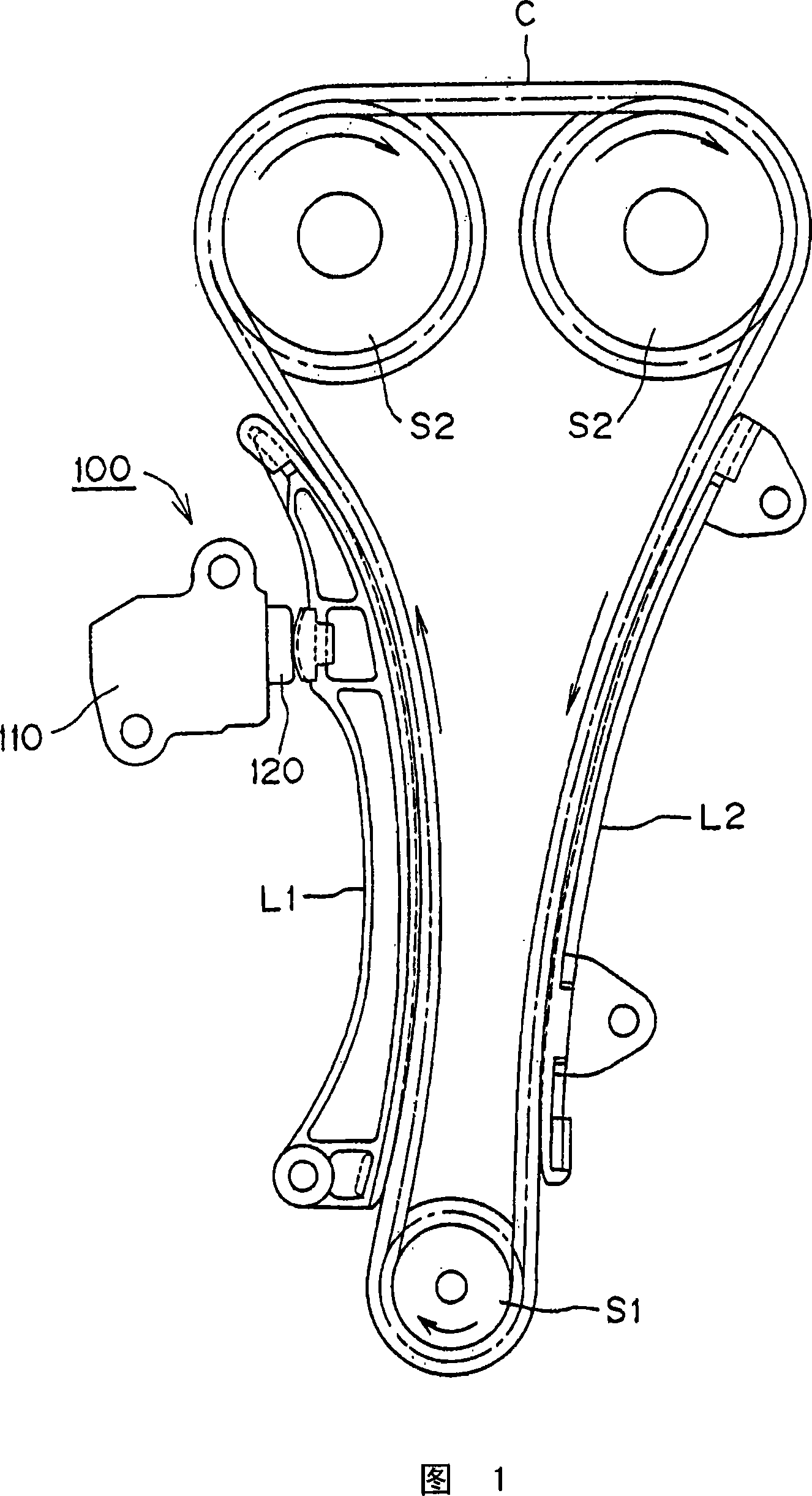

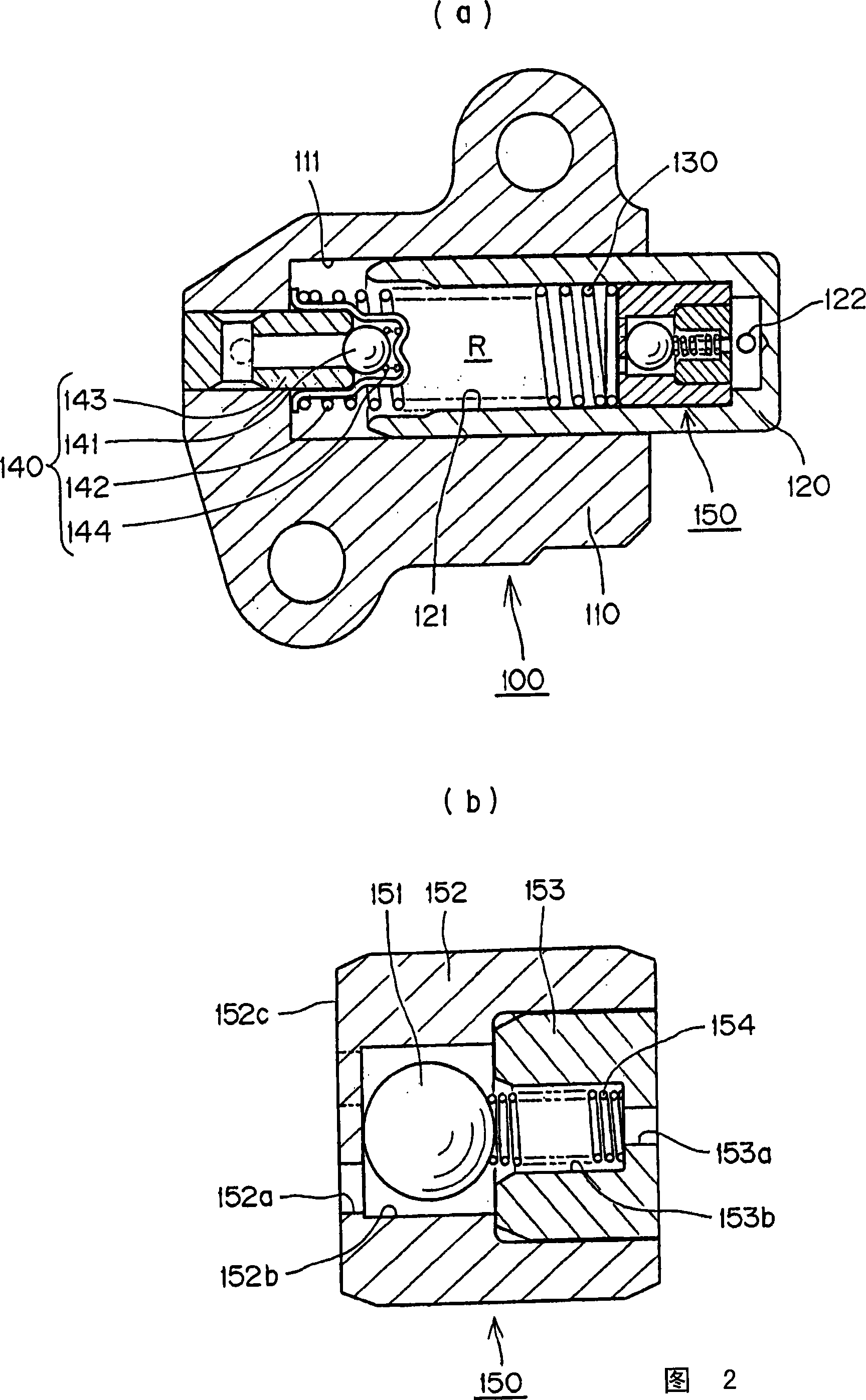

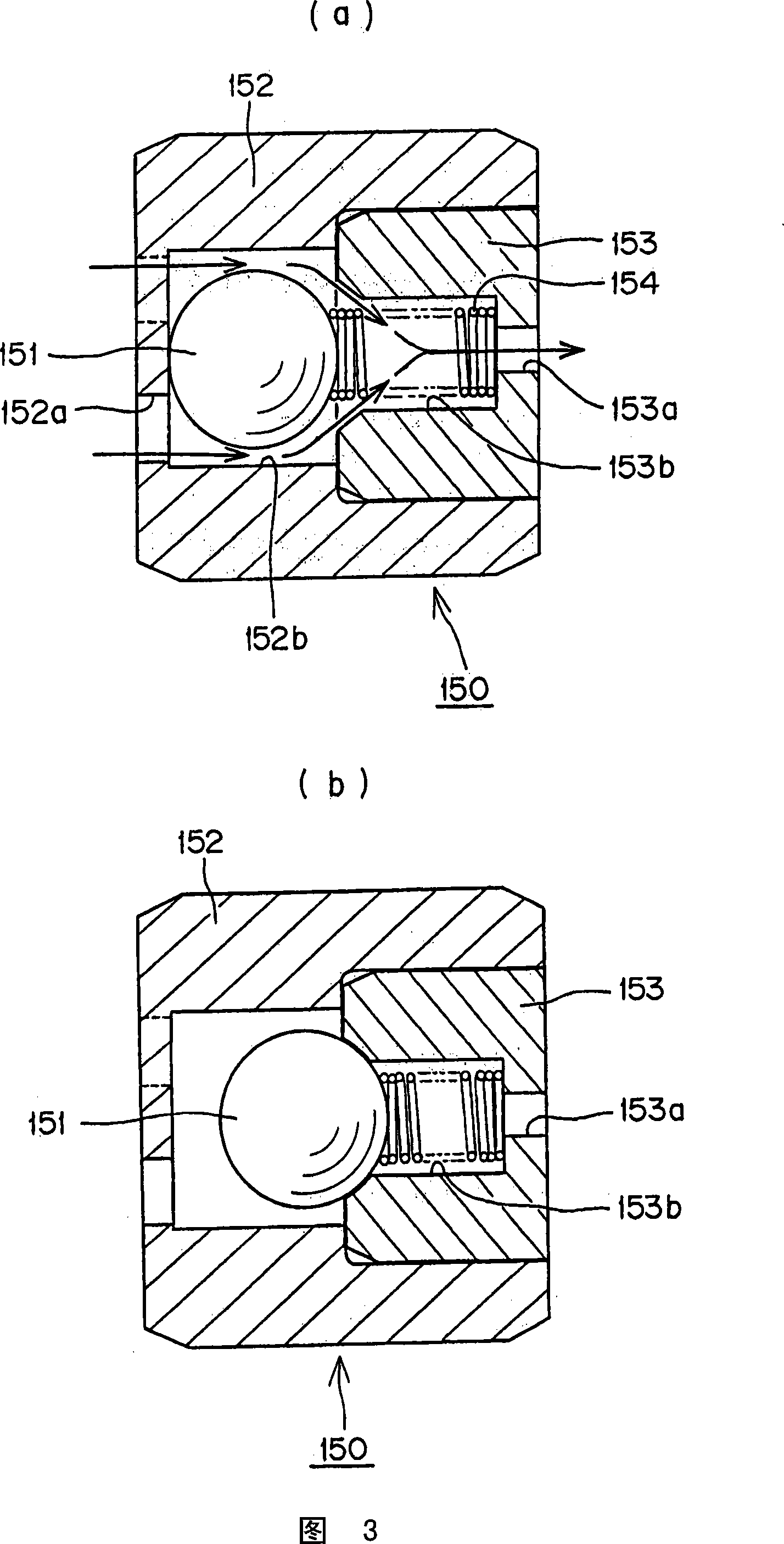

[0021] The degassing type hydraulic tensioner of Example 1 which is one embodiment of the present invention will be described with reference to FIGS. 1 to 3 . Fig. 1 is a diagram of the use status of the degassed hydraulic tensioner of Embodiment 1 of the present invention, Fig. 2 (a) is a sectional view of the degassed hydraulic tensioner 100 shown in Fig. 1, and Fig. 2 (b) is a diagram of Fig. An enlarged view of the one-way ball valve assembly for air relief, designated by reference numeral 150 in (a). Figure 3(a) is a drawing illustrating the exhaust state of the one-way ball valve assembly for air release shown in Figure 2(b), that is, the valve opening state, and Figure 3(b) is illustrating the valve closing state Attached picture.

[0022] First, as shown in FIG. 1 , the degassed hydraulic tensioner 100 according to Embodiment 1 of the present invention is installed on the main body of the engine on the slack side of the timing chain C, and the timing chain C is hung a...

Embodiment 2

[0035] The degassing type hydraulic tensioner of Example 2 which is another embodiment of the present invention will be described with reference to FIG. 4 .

[0036] Figure 4(a) shows the degassing type hydraulic tensioner 200 of this embodiment, its plunger 220 is slidably inserted into the plunger sliding hole 211 formed on the main body 210, and the high-pressure oil chamber R is in the plunger The slide hole 211 is formed between the plunger inner hole 221 formed in the plunger 220 , and the high-pressure oil chamber R accommodates a plunger urging mechanism 230 composed of a coil spring biasing the plunger 220 in a direction to protrude.

[0037] In addition, at the bottom of the plunger sliding hole 211, a one-way valve assembly 240 is installed to allow hydraulic oil to flow into the high-pressure oil chamber R formed between the plunger sliding hole 211 and the plunger inner hole 211 and prevent it from flowing backward. .

[0038] The one-way valve assembly 240 is an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com