Cold rolled strip resolved cutting flying shear blade primary clearance scaling device and scaling method thereof

A technology for cold-rolled strip steel and initial gap is applied in the field of initial gap calibration tools for high-speed slitting flying shears. Achieve the effect of overcoming quality problems, easy operation, and improving accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

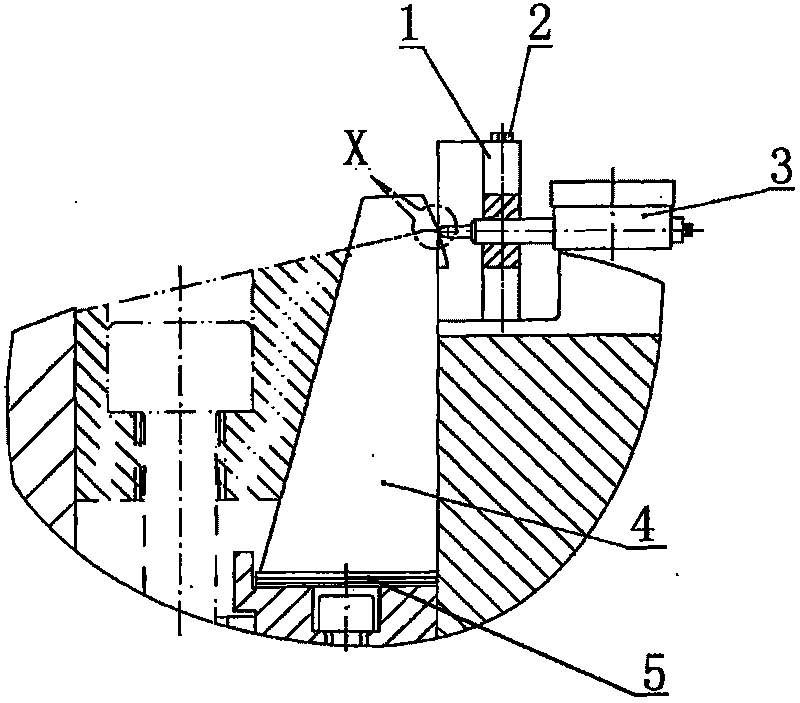

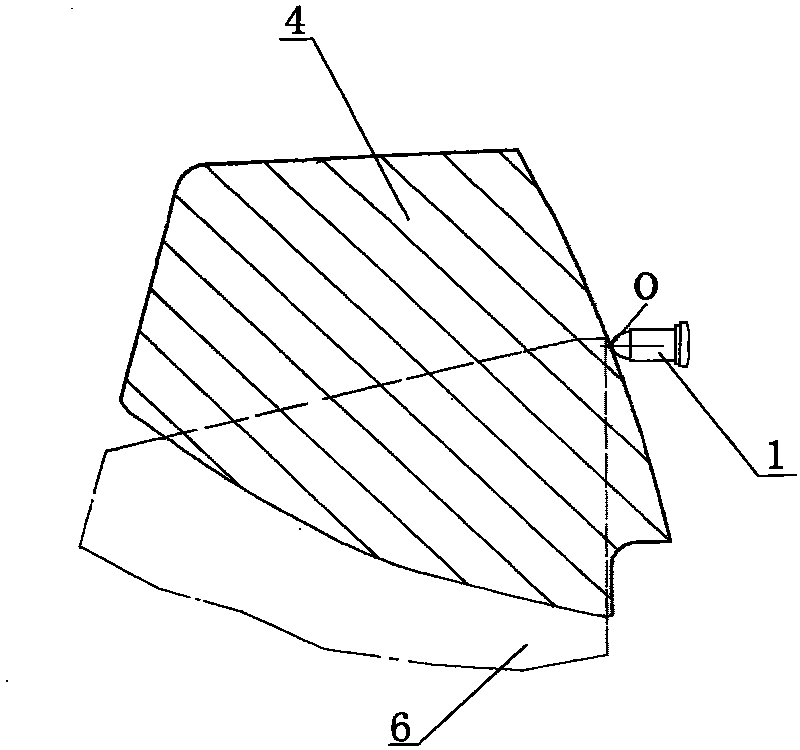

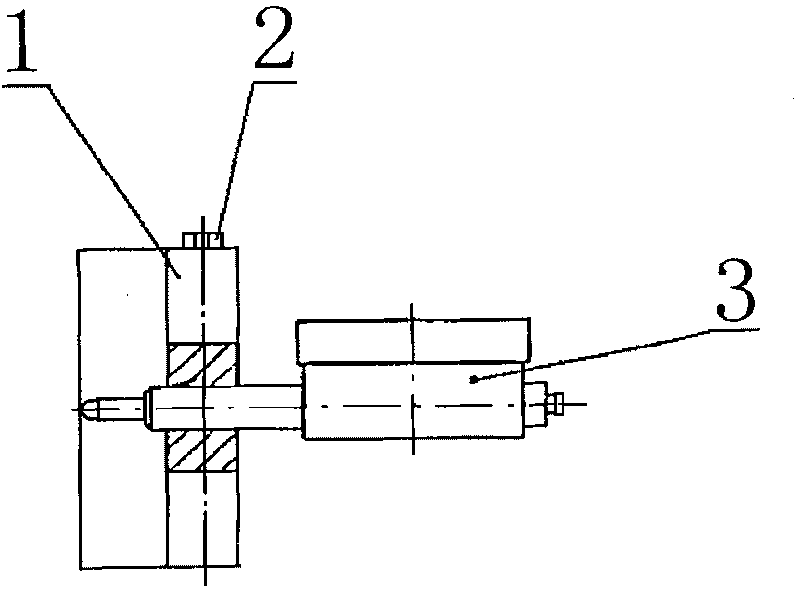

[0016] attached Figure 1~3 The calibration principle diagram and device diagram of the present invention are given. The present invention will be further described below in conjunction with accompanying drawing. As shown in the drawings, the calibration device of this embodiment is composed of a calibration plate 1, a locking screw 2, and a dial gauge 3. figure 1 The two wedges 4 are installed on the hub together with the cutting edge 6, and are located on both sides of the cutting edge in the length direction, and the adjustment shim group 5 is installed under the two wedges 4. attached by figure 2 It can be seen that the working surface of the wedge 4 is an involute curve. After the shear blade 6 and the wedge 4 are installed on the hub, the engagement point O on the wedge 4 protrudes outward from the shear plane along the horizontal direction. 0.05mm, and the two wedges 1 are meshed at point O, and the gap between the two wedges 1 at point O is 0; therefore, the gap b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com