Enhanced side-by-side mooring construction

An offshore, floating technology, applied in the direction of anchorage arrangement, ship construction, towing/push equipment, etc., which can solve the problems of operational feasibility constraints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

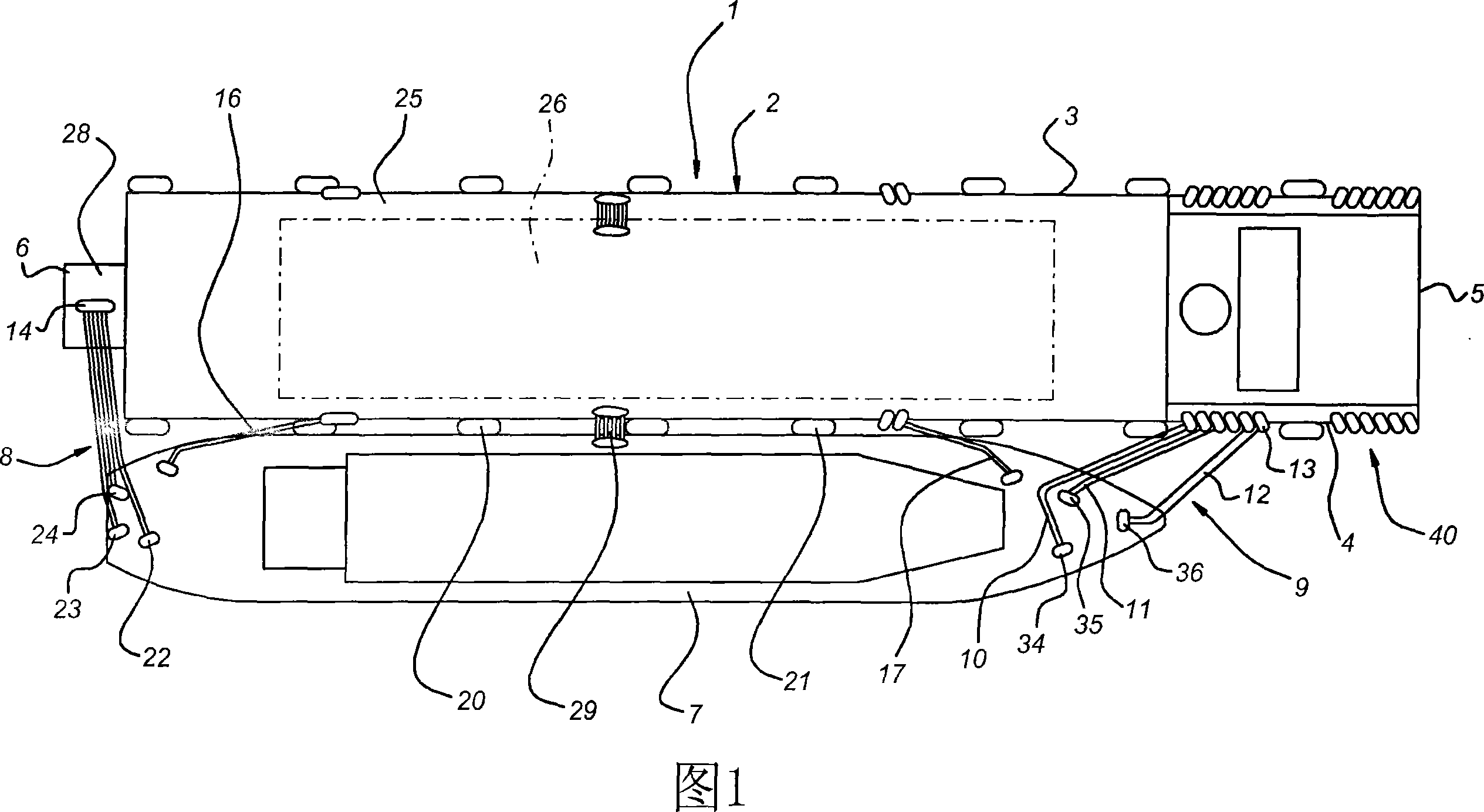

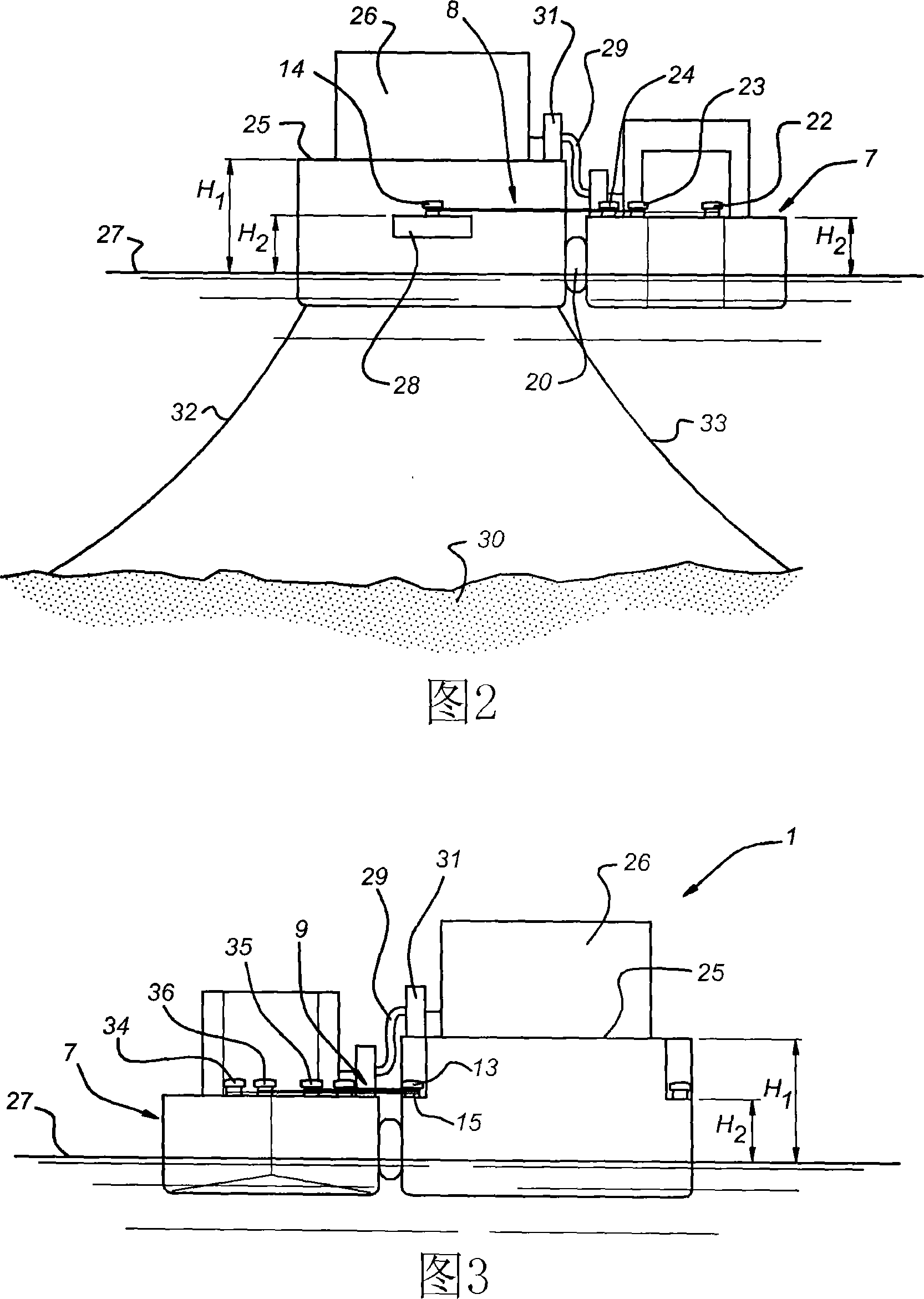

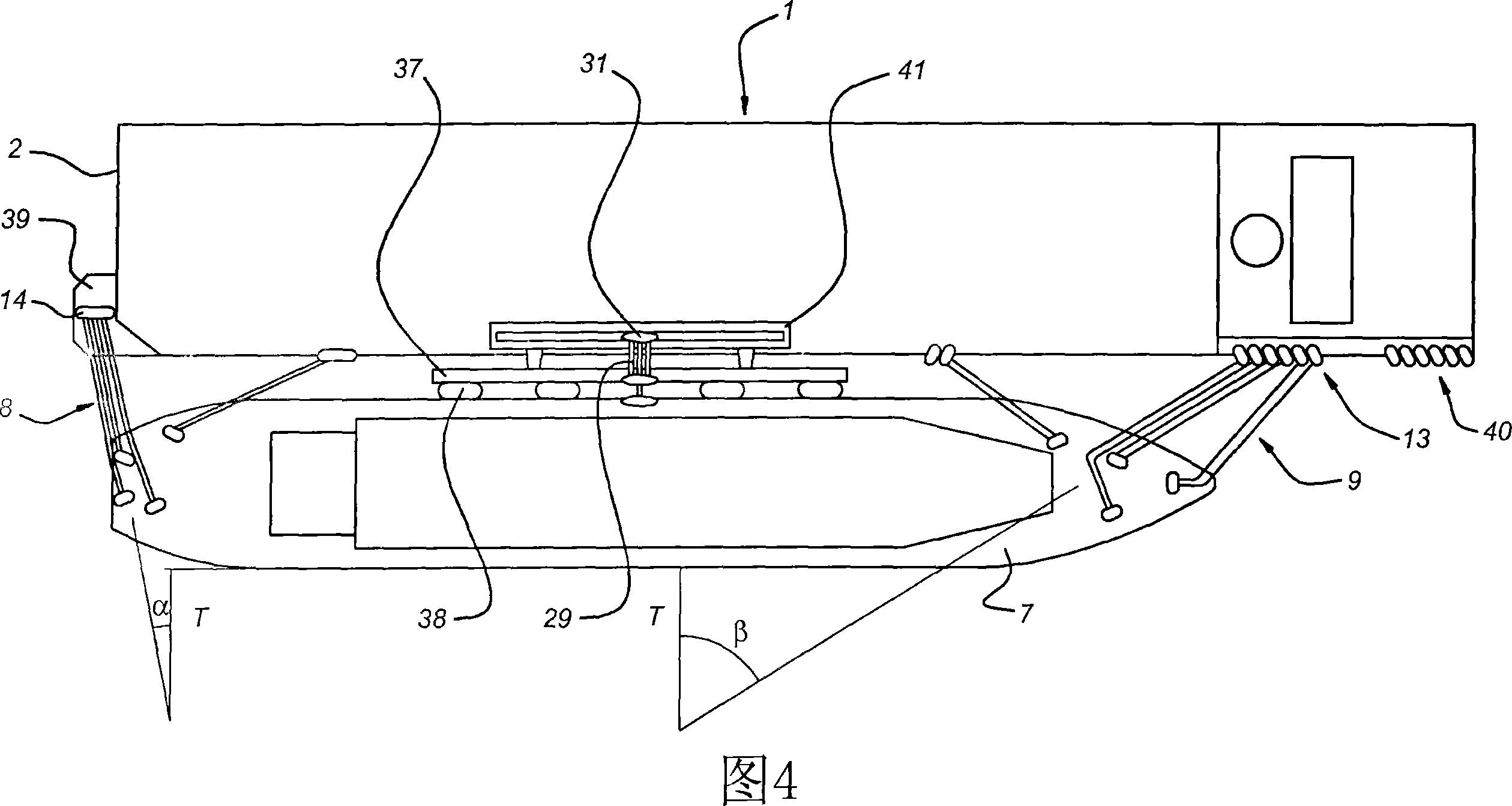

[0024] Figure 1 shows an offshore structure 1 such as a newly constructed FSRU or a newly constructed floating production storage offloading unit FPSO that changes orientation with the wind. The structure 1 comprises a hull 2 with longitudinal sides 3, 4 and transverse sides 5, 6 at the bow and stern. A tanker 7 is moored along the structure 1 via groups of mooring lines 8, 9 at the bow and stern. The bow mooring lines 9 (beam lines) comprise three groups 10 , 11 , 12 of two parallel mooring lines each, which are attached to six bow anchor points 13 on the structure 1 . The rear mooring lines 8 (cross lines) also comprise three groups of two parallel lines each, attached to the stern anchor points 14 on the structure 1 . Elastic mooring lines 16, 17 extend from aft and forward positions respectively on the vessel 7 towards anchor points on the structure 1 near midship. A number of elastic fenders 20 , 21 are located between the tanker 7 and the structure 1 against which th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com