Temperature fuse connection structure

A technology of thermal fuse and connection structure, applied in the direction of protection switch operation/release mechanism, emergency protection device, heating/cooling contact switch, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0057] In order to reveal the purpose, features and effects of the present invention in detail, the present invention will be further described in detail according to the following preferred specific embodiments and accompanying drawings as follows:

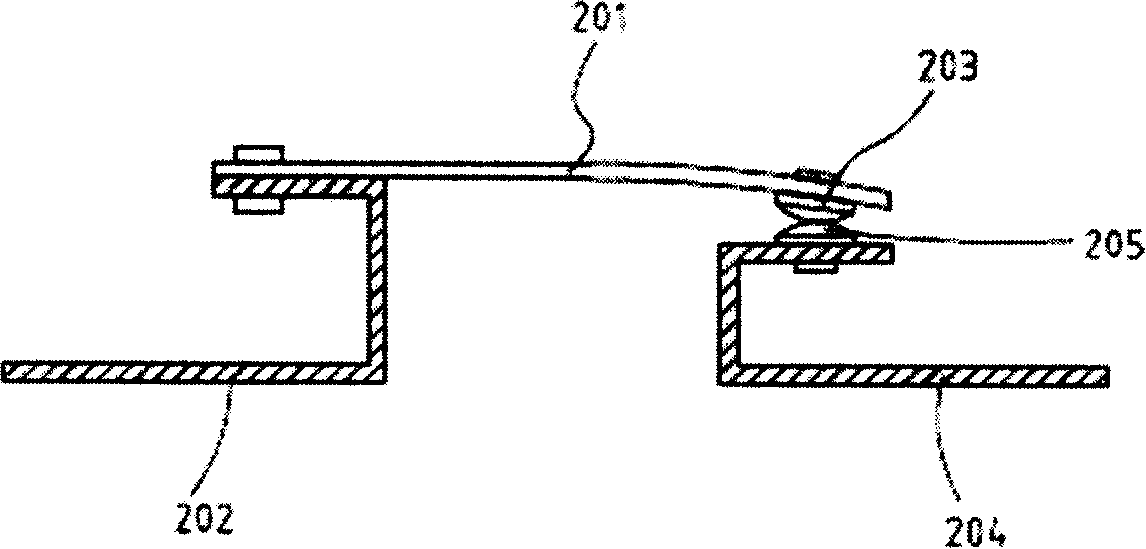

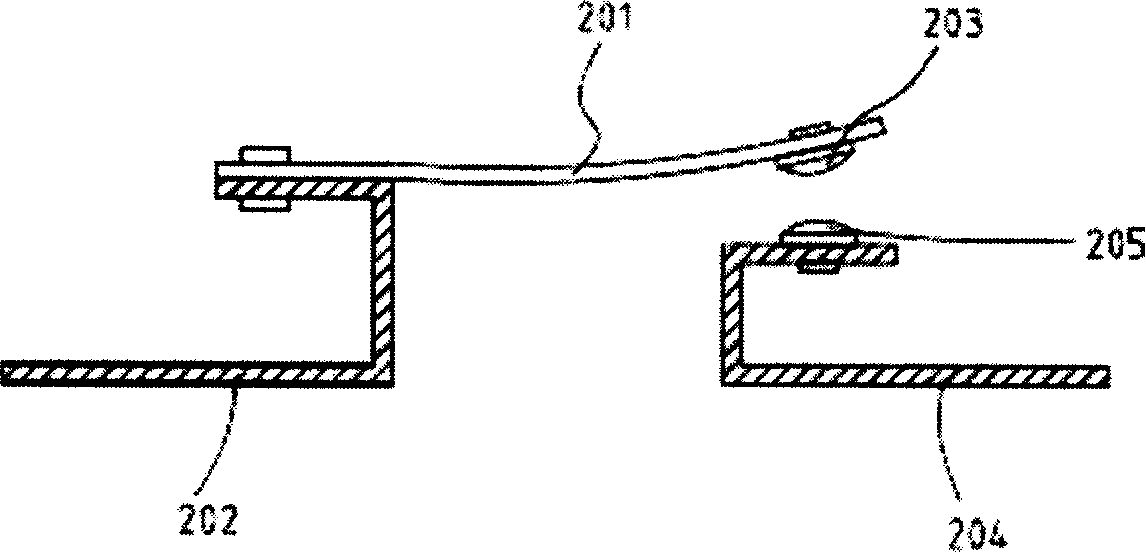

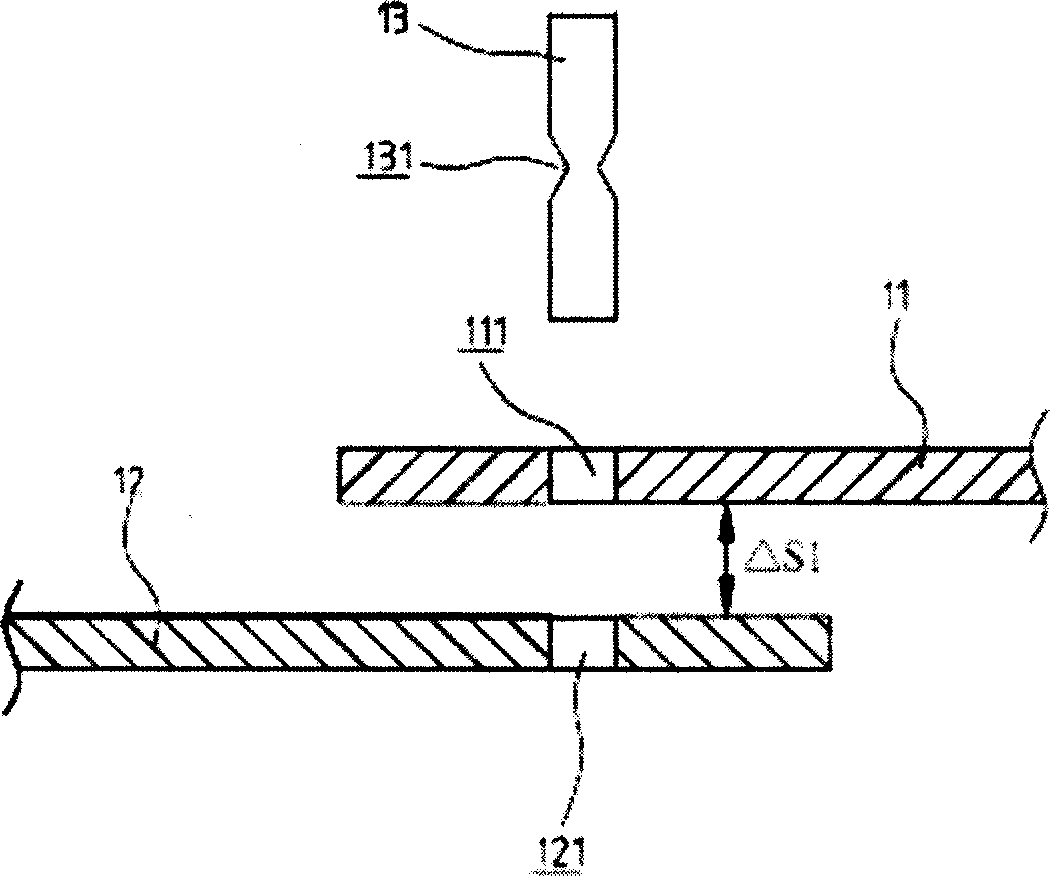

[0058] Such as image 3 , Shown in 4, is an anatomical view and a combined cross-sectional view of an embodiment of the present invention; Figure 5 When the current is overloaded or the circuit is overheated, the hot melt metal is heated and the temperature rises and melts and breaks. The free ends of the two terminals are not connected to each other, and the circuit becomes an OFF state schematic diagram; The temperature fuse connection structure mainly includes two terminals (11, 12) and a hot melt metal (13); among them,

[0059] The two terminals (11, 12) are fixedly arranged in the circuit line, and the two free ends of the two terminals (11, 12) are respectively provided with traversable openings (111, 121), the openings (111,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com