Semiconductor package structure and manufacture method thereof

A packaging structure and manufacturing method technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as difficult, difficult to detect packages, production costs and time waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The detailed description is as follows, and the preferred embodiment is only for illustration and not intended to limit the present invention.

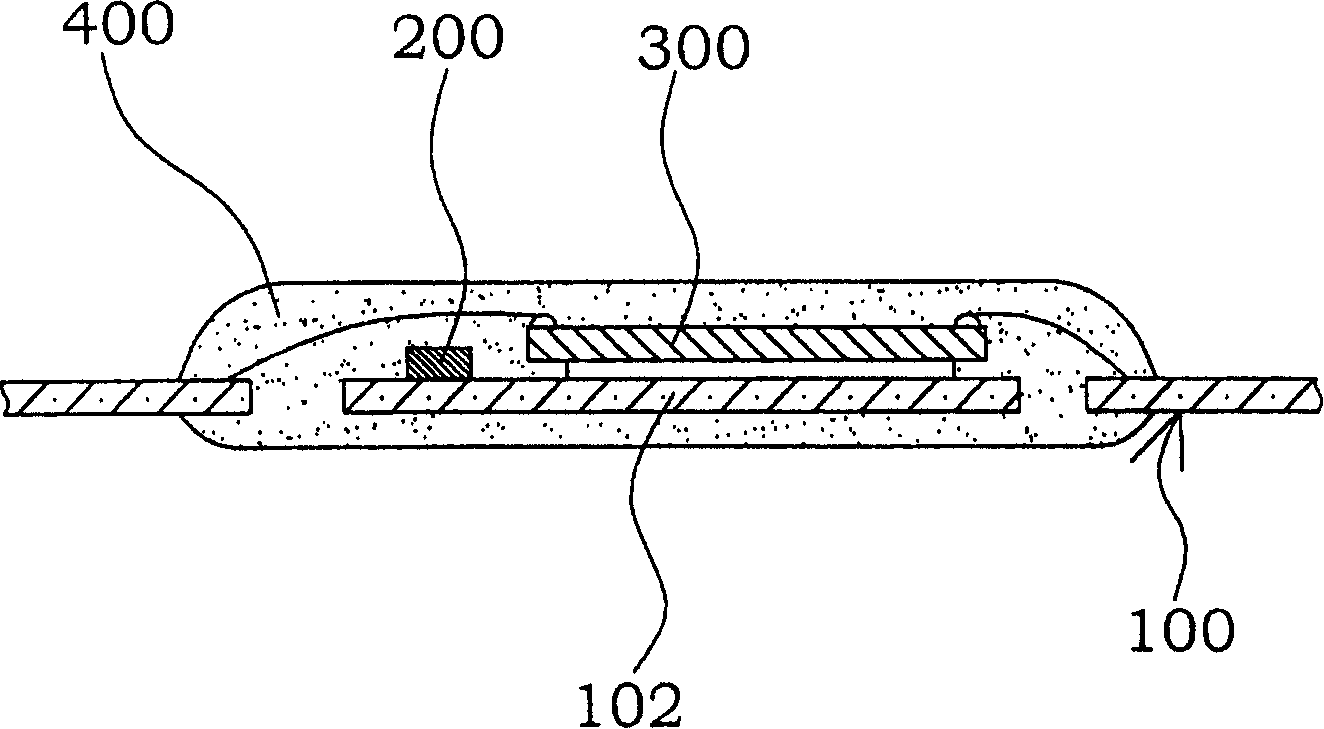

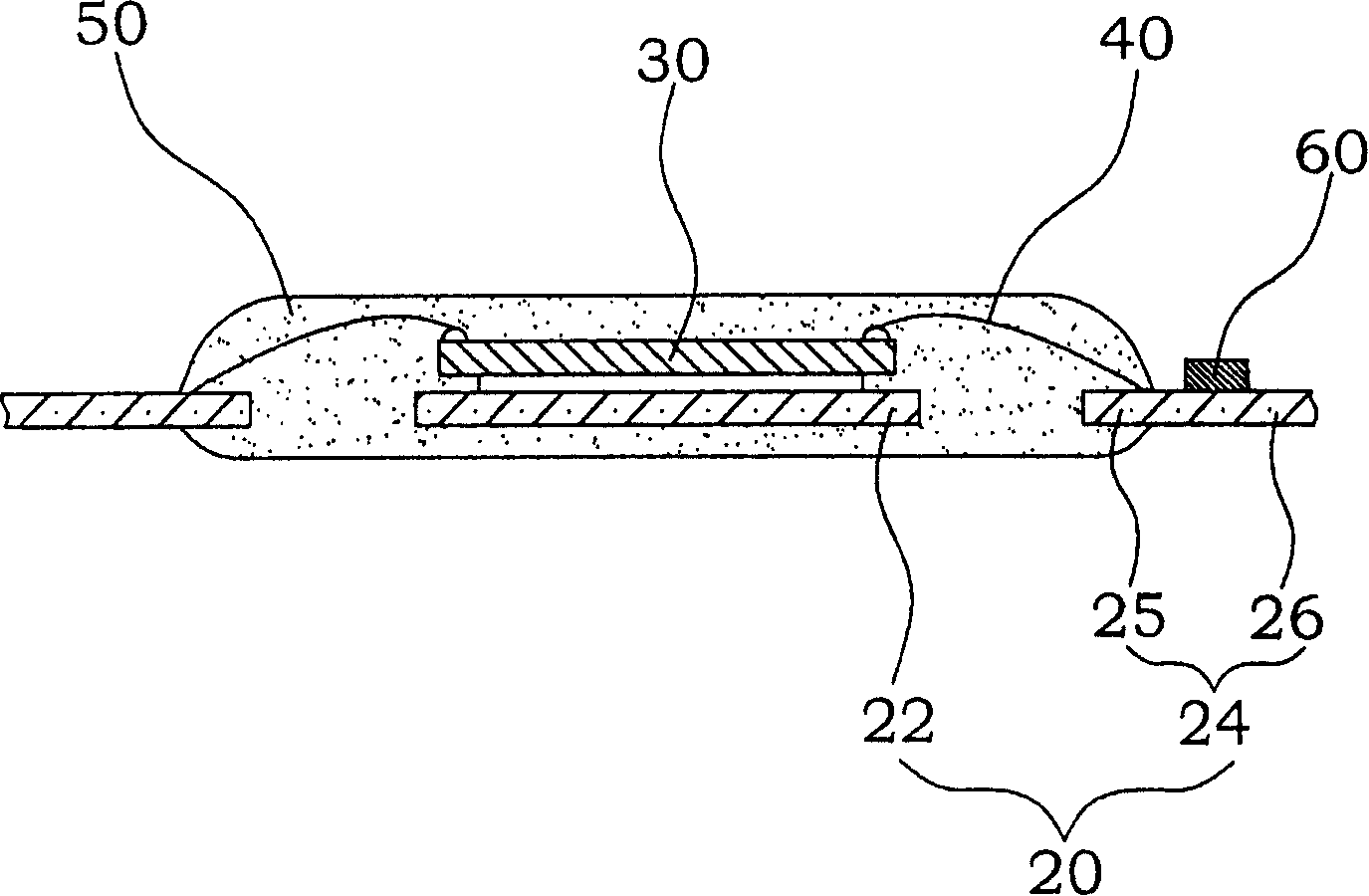

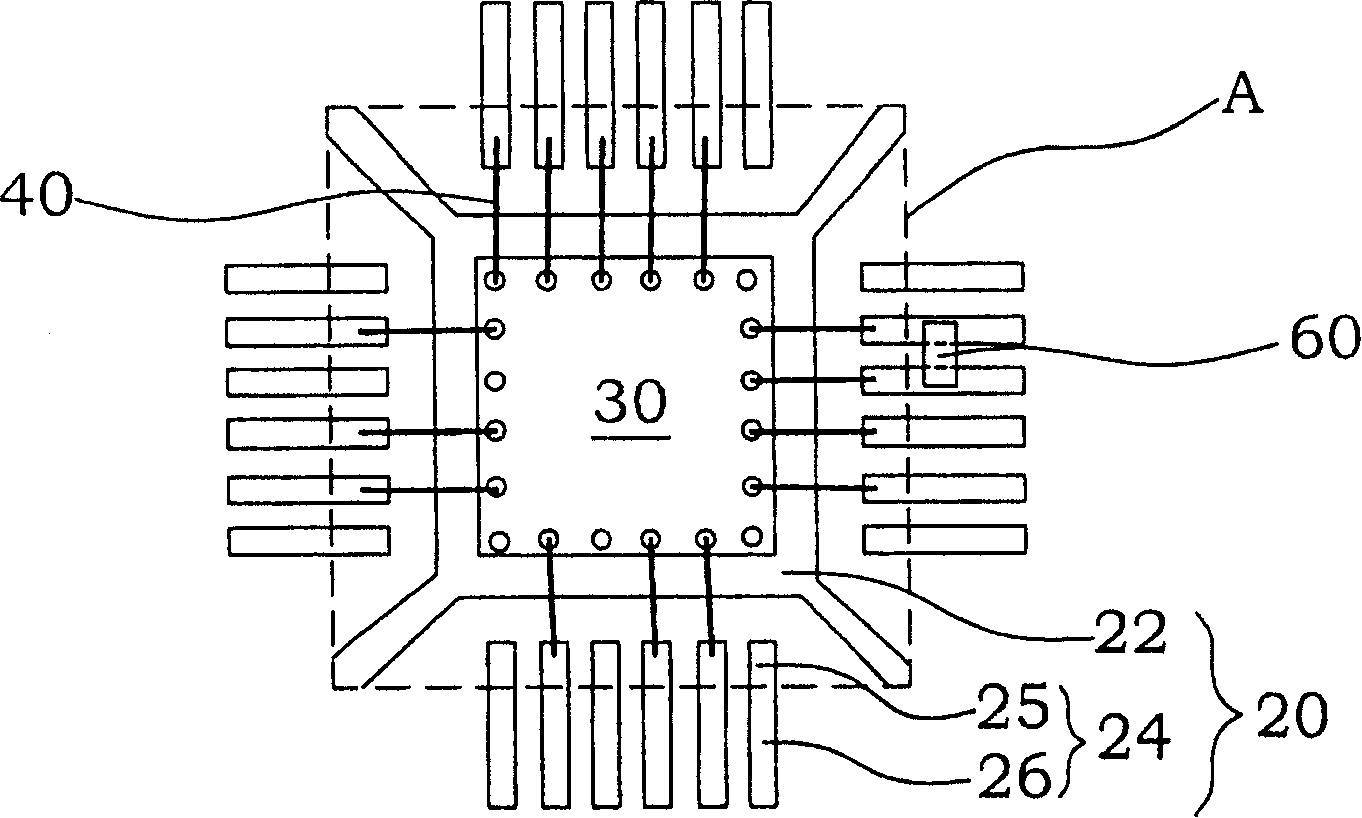

[0036] figure 2 Shown is a cross-sectional view of a semiconductor package structure according to an embodiment of the present invention. In this embodiment, the semiconductor packaging structure includes a lead frame 20 , a chip 30 , a molding compound 50 and a passive element 60 . like figure 2 As shown, the lead frame 20 contains a support member 22 and a plurality of pins 24, wherein any pin 24 contains an inner pin portion 25 and an outer pin portion 26; the chip 30 is in a suitable manner, such as a pasting method, It is arranged on the support member 22, and uses a conductive connecting element 40 to electrically connect the inner pin portion 25; a packaging compound 50, covering the chip 30, the conductive connecting element 40 and the inner pin portion 25 of the lead frame 20, on a In an embodiment, the material o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com