Article loading in case amount detecting and rejecting mechanism for package machinery

A technology for rejecting mechanisms and packaging machinery, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of unqualified packaging products, troubles, inconvenient product procedures, etc., and achieve the effect of improving product qualification rate and reducing work burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

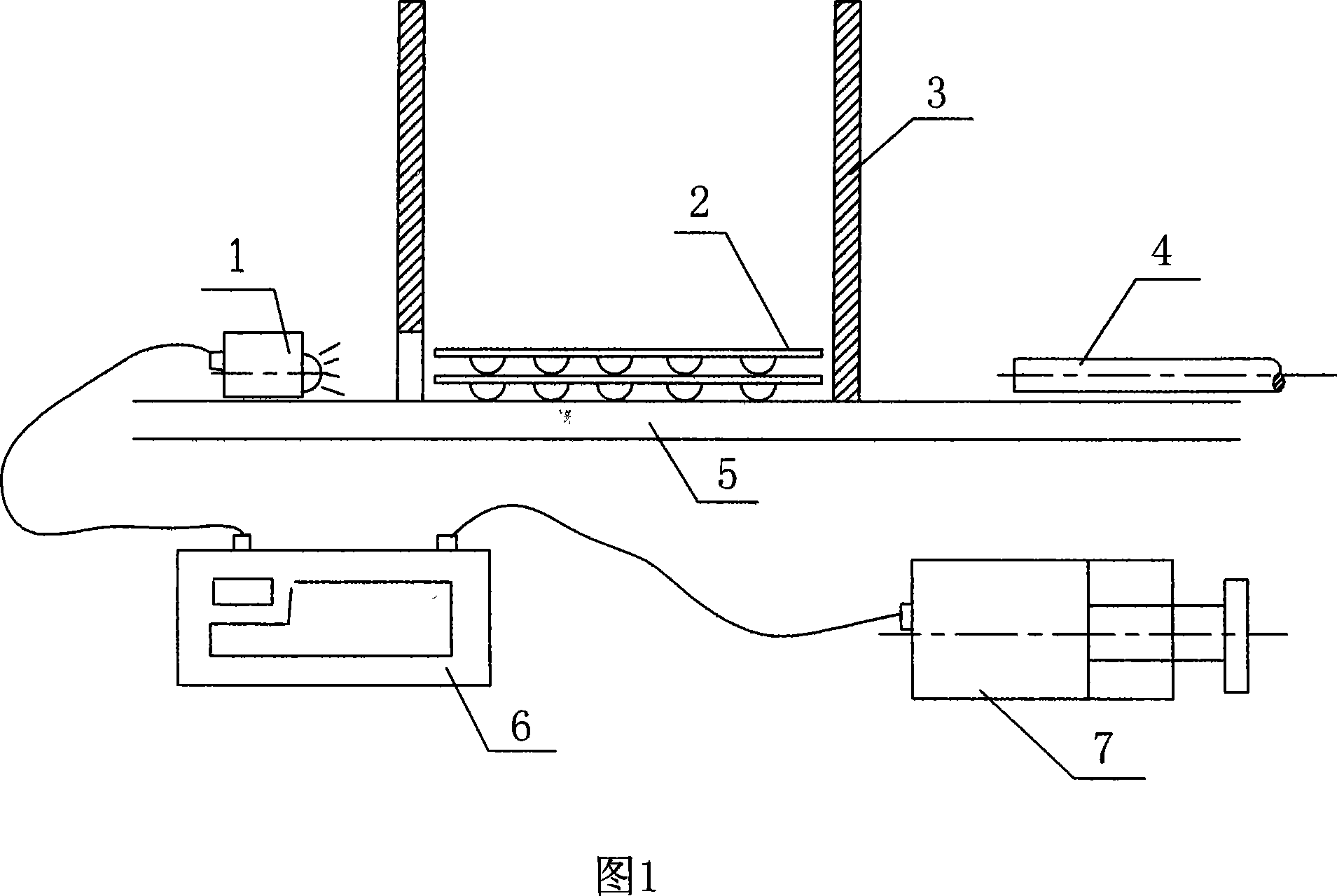

[0011] Referring to Fig. 1, a CCD light head image detection mechanism 1 is installed near the pushing mechanism 4 (i.e. near the feed medicine plate), the light head of the CCD light head image detection mechanism is facing the cross section of the feed medicine plate 2, and the CCD light head image detection The mechanism is connected to the CPU controller 5 by the control line, and the CPU controller is connected to the automatic rejecting mechanism 7 by the control circuit. The automatic rejecting mechanism is installed at the delivery part of the packaged product output. The automatic rejecting mechanism can be a hydraulic propulsion device or an electric propulsion device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com